Furnace Flues for Construction of Boilers

fig and flanged

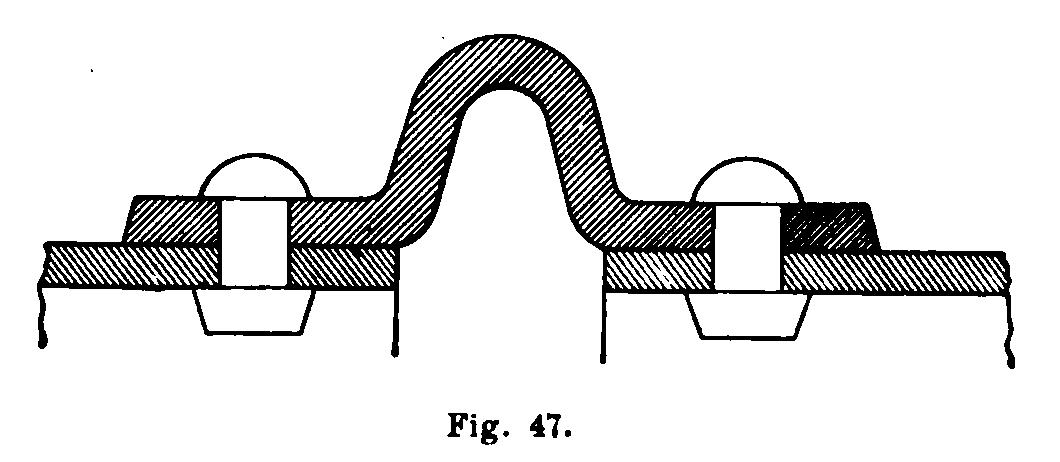

FURNACE FLUES FOR CONSTRUCTION OF BOILERS Flues which are subjected to external pressure should always be cylindrical. Fig. 45 shows the section of the Adamson flue. This was an improvement over the plain furnace, as it is more elastic and allows expansion ; the flanged rings also strengthen and stiffen it against collapse. The methods of building furnaces shown in Figs. 46 and 47 are not considered as good as the Adamson arrangement. Fig. 46 is too rigid, and does not allow a free expansion and contraction. Fig. 47, on the other hand, permits of such extremely well, but both have the fault of exposing a double thickness of plates and two rows of rivets to the fire.

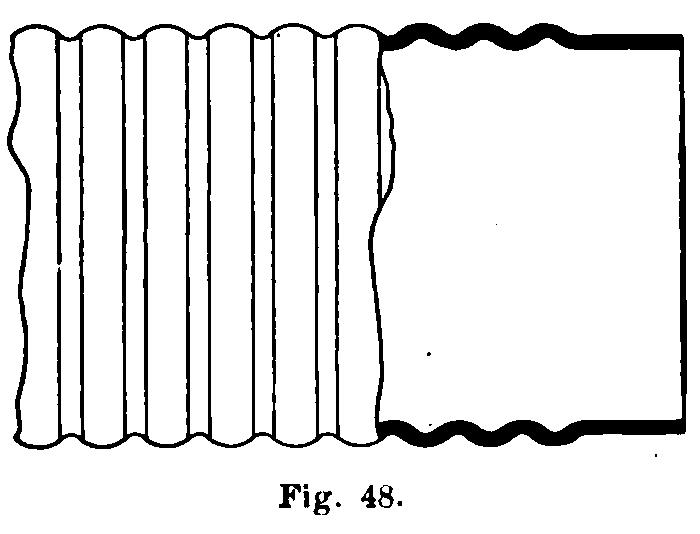

The corrugated flue shown in Fig. 48 is popular and, furthermore, is excellent. There is freedom for expansion throughout its whole length, thereby reducing the strains on the boiler.

The plates should be thick enough to prevent sagging in the middle, the thickness usually varying from 5/16 inch to 5/8 inch. Corrugated furnaces are riveted to the rear tube sheet in the return tube boiler of the marine type, the end of the furnace being flanged at the front; and the head of the boiler is flanged around the opening cut for the furnace, which fits well into the flange.