Rivets and Riveting

joint and butt

RIVETS AND RIVETING.

Rivets are formed by forging, from round iron bar or mild steel, with a cup or pan shaped head. The cylindrical part, called the shank, is a little smaller than the hole and has a slight taper. Fig. 3 shows common forms of rivets. As rivets are not as reliable in tension as in shear, they are used mainly at right angles to the straining force. If the stress is parallel to the axis, bolts are used, since they are strong in tension. The shearing strength of steel rivets is about 45,000 pounds per square inch, and of iron rivets about 40,000 pounds per square inch. Steel rivets are often used with steel plates, but many boiler makers prefer to use iron rivets in all cases.

Three types of rivets in use are shown in Fig. 4, the following table giving the dimensions: Formerly all joints of boilers were riveted by hand, but now all riveting is done by machines, except those joints to which a machine cannot be applied. If done by hand, the red-hot rivet is inserted in the hole, and the second head formed by two riveters working with hammers. This head is either made conical by the hammers alone or finished with a cup-shaped die called a "snap." This latter is the more usual method. The disadvantages of hand riveting are slowness and a tendency to form a shoulder before the rivet fills the hole.

Machine riveting is preferable, as the work is done better, faster and more accurately ; the pressure coming gradually on the entire rivet, compresses it completely into the hole before the head is formed. Before riveting, care should be taken that the plates are close together, so that a shoulder will not be formed between the plates and prevent a good joint. Rivets should always be put in while red hot, for in this condition they are more easily worked, and when they cool they contract, nipping the plates together in a tight joint.

Hydraulic riveting is more gradual and is generally preferred to steam riveting. The pressure from the steam riveter often comes as a sudden blow and does not allow time for the rivet to completely fill the hole.

It is sometimes desirable to rivet with a countersunk head; that is, the rivet does not project above the plate. The countersunk head is formed by hammering down the end of the rivet into the countersink in the plate. This form is shown at D, Fig. 3. This joint is often used in shipbuilding and in boiler making when it is necessary to attach mountings. It should always be avoided, if possible, on account of its weakness, and especially when the straining force acts in the direction of the length of the rivet, as the head has a very insecure hold and is likely to be pulled through the hole.

Rivets may be tested in a boiler shop as follows : the rivet to be bent cold in the form of a hook around another rivet of the same diameter, and show no flaws or cracks ; to be bent hot down upon itself and show no cracks, head to be flattened while hot until its diameter is 24 times the diameter of the shank, and show no flaws.

The uniform heating of steel rivets is of more importance than in the case of iron rivets, where it is sufficient to heat the points only.

Steel rivets also should not be heated to a white heat, as iron rivets are, but to a bright cherry red, for if heated beyond this point they will burn. The fire in which steel rivets are heated should be kept thick, and the draught moderate. This should also be observed in heating steel plates for flanging.

There are various forms and strengths of riveted joints. It is obvious that in punching or drilling, a plate is weakened to the extent of the sectional area cut out, and that if the holes are punched, the metal between the holes is weakened. In treating the strength of a joint it is customary to speak of it as a percentage of the strength of an unpunched plate.

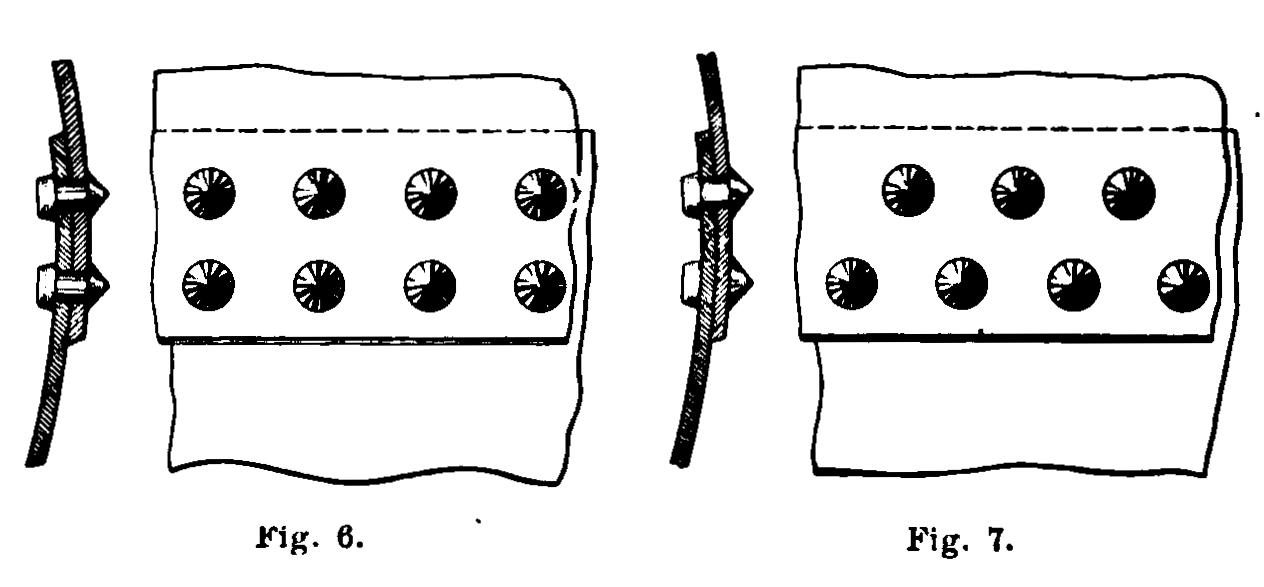

If one plate overlaps another and is riveted to it by a single row of rivets, as shown in Fig. 5, it is called a single-riveted lap joint. This joint has about 56 per cent of the strength of a solid plate. If another row of rivets is added, it is called a doubleriveted lap joint; Fig. 6 shows the double-riveted lap joint chain riveted, and Fig. 7 the double-riveted lap joint zigzag riveted.

Double riveting is done in two ways : zigzag, or staggered, and chain. When rivets are put in so that the rivets of one row are opposite the spaces of another row, it is called zigzag riveting or staggered riveting. If the rivets are placed immediately opposite each other, it is called chain riveting.

If the two plates are kept in the same plane and a cover or butt strap riveted on, it is called butt riveting (Fig. 8, in which A and B are the boiler plates, and C is the butt strap). If an inside butt strap is added, it is called a double butt joint (Fig. 9). Fig. 10 shows a treble-riveted butt joint. A single butt joint is about equal in strength to a lap joint having but one row of rivets, but a double butt joint is considerably stronger.

In this latter form of joint the rivets have double shearing surfaces, since they tend to shear off in two planes. This either makes a stronger joint or allows the use of smaller rivets. In the single butt joint the butt strap is usually about 1 the thickness of the plate, and if the inside butt strap is added, each butt strap is made about the plate thickness. Butt joints are now being used in the best class of boilers, and are used almost entirely for plates less than inch in thickness.

Lap joints are used for circumferential seams, and the stronger joint, the butt, for longitudinal joints. For high pressures in marine boilers, triple riveting is frequently used.

If a cover plate is riveted on the outside of a lap joint, it is called combined lap and butt join t. In this case there are three rows of rivets, the middle row having twice as many rivets as the outer rows. Fig. 11 shows the combined joint.

The distance between the centers of rivets is called the pitch." The mathematical calculation of pitch and the distance between the rivets and the edge of the plate will be taken up later.

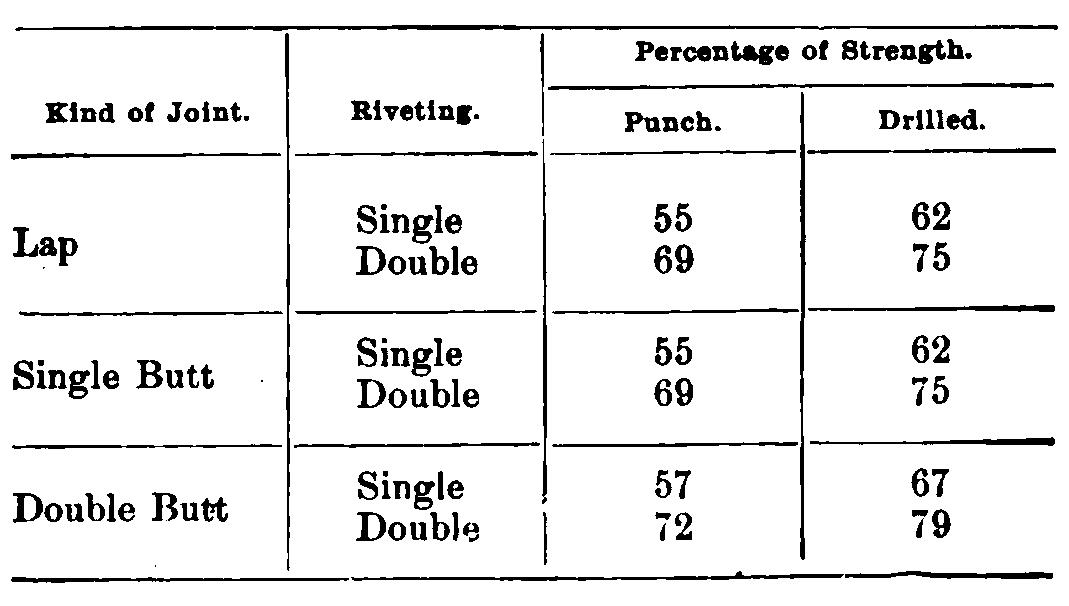

The following table gives an idea of the relative strengths of riveted joints :