Staying for Construction of Boilers

stay and stays

STAYING FOR CONSTRUCTION OF BOILERS The shell is now ready to receive the stays. When under steam, a cylindrical shell is strained by internal pressure in two directions, namely : transversely, by a circumferential strain due to the pressure tending to burst the shell by enlarging its circumference, and longitudinally, by the pressure on the ends. If a boiler were spherical it would require no stays, because a sphere subjected to internal pressure tends to enlarge but not to change its shape. All flat surfaces in boilers must be stayed, otherwise the internal pressure would bulge them out and tend to make them spherical in shape. The ends of steam drums on high-pressure water-tube boilers are often made hemispherical.

The first and most important point in staying is to have a sufficient number of stays so that they will entirely support the plate without regard to its own stiffness. The second is to have them so placed as to present the least obstruction to a free inspection, and third, to have them so arranged as to allow a free circulation of water. Too much care. cannot be taken in fitting stays and braces, as they are out of sight for long periods, and a knowledge of their exact condition is not always easily obtained. In the ordinary fire-tube boiler the principal surfaces stayed are: the flat ends, crown sheets, flat sides of locomotive boilers and combustion chambers of cylindrical marine boilers. In t h e case of most marine or Scotch boilers, the diameter is large compared to the length ; hence the flat surface is considerable, and needs careful staying. All the plates that are not cylindrical or hemispherical must be stayed. The details should be arranged for each boiler ; a few general methods and cautions can, however, be given.

The most common and simple form of stay. is a plain rod. It is used to stay the flat ends of short boilers. This stay is a plain rod passing through the steam space and having the ends fastened to the heads. The ends are fastened and the length adjusted in a variety of methods ; the simplest being nuts on both sides of the plate, as shown in Fig. 28. The copper washers a and b

strengthen the plate and prevent abrasion by the nuts. In place of the nuts the rod is often bolted to angle irons, which are riveted to the plates. In this case, turn buckles similar to the one shown in Fig. 29 are used for adjusting the length.

The stays are usually from 1/4 inch to an inch in diameter, and are made of wrought iron or steel, with an allowable stress of 5,000 to 7,000 pounds per square inch. If the ends are fastened to riveted angle irons, the combined area of the rivets is made a little greater than that of the rod.

If a boiler is long, that is, more than 20 feet, long stays would sag in the middle and not take up the full stress on the end plates. For long boilers, gusset and diagonal stays are used. This form of boiler stay, shown in Fig. 30, is made of wroughtiron plate riveted to angle irons ; the angle irons being riveted to the end and shell. Boilers of the Cornish, Lancashire and Galloway types often have this kind of stay. These boilers are internally fired, and as the 'variation of temperature causes expansion and contraction, great care should be used in placing the gusset stay. If the stay is too near the flange or too many stays are used, the head will be too rigid and have a tendency to crack.

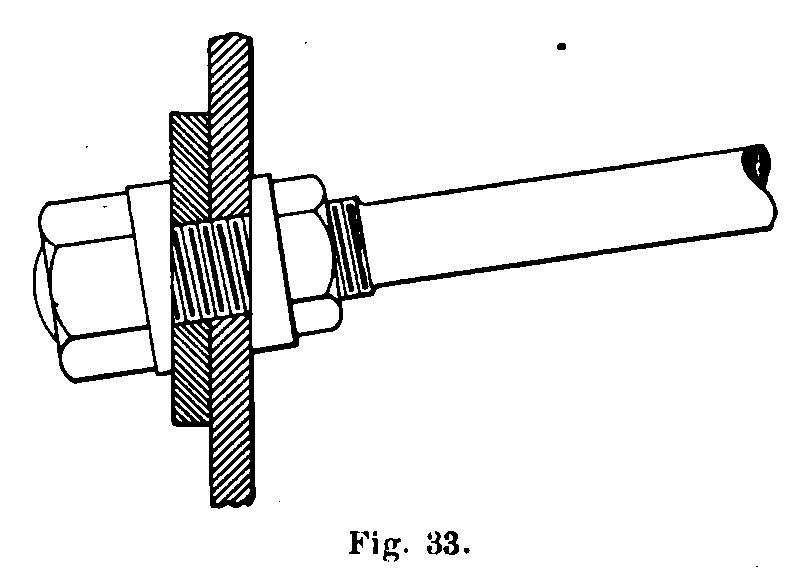

A form of diagonal stay is shown in Fig. 31. The plain rod is connected to angle irons by means of split pins. The angle irons are fastened to the shell and end by rivets or bolts. Another form of diagonal stay, called the crowfoot, is shown in Fig. 32. The two ends are bolted or riveted to the end and shell.

The angle between the shell plate and stay rod should be small,— not more than 30 degrees. The rod itself is designed for tensile strength, since the diagonal pull may be easily reduced to an equivalent direct pull. A large factor of safety is used to provide for future corrosion.