Tubes for Construction of Boilers

tube and shown

TUBES FOR CONSTRUCTION OF BOILERS Boiler tubes are made of steel or wrought iron, but most commonly of charcoal iron and lap welded. In the formation of the lap the plate is upset, then bent around until the thickened edges lap sufficiently. It is then heated successively about 8 inches at a time, and welded over a mandrel, which is a cast-iron arm with a slightly convex top, over which the tube is placed Tubes are measured by their. outside diameters, and are usually true to gauge, so that holes for them may be bored without taking measurements from the tubes themselves.

The holes for the tubes in the tube sheet are usually made in one of two ways. One method is to punch the tube holes the proper size by means of a helical punch. With this punch the metal is cut away by a shearing cut. The holes ought to be punched a little under size, and then reamed out, so that the surface against which the tubes are expanded may be good. The other method is to punch or drill a small hole at the point marking the center of the tube. hole. A drill with a post in the center. which fits the small hole, then drills the desired size of hole.

Ordinary tubes are fastened to the end plates by expanding the metal of the tube against the tube plate. This is done by a tool called an expander, of which there are two common forms. One form consists of a steel taper pin and a number of steel segments, held in place by a spring. The outside of the segments have the form to be given to the expanded tube, and the inside is a straight hollow cone, into which the steel taper pin fits. The segments are forced apart by hammering on the steel pin. In order that the metal of the tube may not be injured, the hammering should be done gradually and carefully, and the expander turned frequently. Another form, shown in Fig. 89, has a set of rolls that are forced against the inside of the tube by driving in the taper pin. The pin and rolls rotate as the pin is driven, and the rolls gradually expand the tube against the tube plate.

Two forms of tube expansion are shown in Figs. 40 and 41. That shown in Fig. 41 is preferable to that in Fig. 40, as the latter bears at the corners only, while the former bears against the entire thickness of the tube sheet.

After the tubes are expanded, the ends are beaded over, as shown in Figs. 40 and 41. This adds to the strength of the connection between the tube and tube sheet. The tool commonly used for this beading is shown in Fig. 42.

Ferrules are often placed in the ends of fire tubes, and serve to protect the ends from the intense heat of the fire. The arrangement is shown in Fig. 43, the ferrule F being placed within the tube for a short distance. The space A is merely an air space.

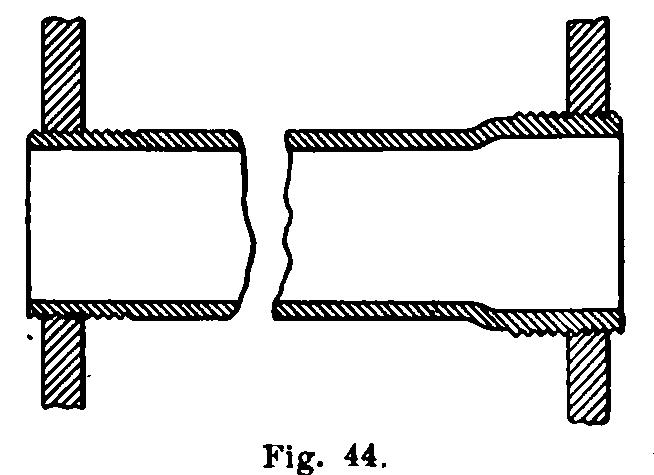

Stay tubes are not used as extensively at the present time as they were formerly. They were very common at a time when the holding power of expanded tubes had been experimented on but little. It is now apparent from such tests that the holding power of tubes expanded, as shown in Fig. 40, is more than equal to the pressure on the spaces between the tubes of an ordinary tube plate. Stay tubes are simply heavier tubes, with the ends pro.

jetting beyond the tube sheet and threaded for shallow nuts. The ends of the tubes are frequently upset or thickened, and screwed into the tube sheet as well. This form is shown in Fig. 44.