Fire-Box Boilers - Locomotive Type Horizontal Many Small Fire Tubes Externally-Fired

box and boiler

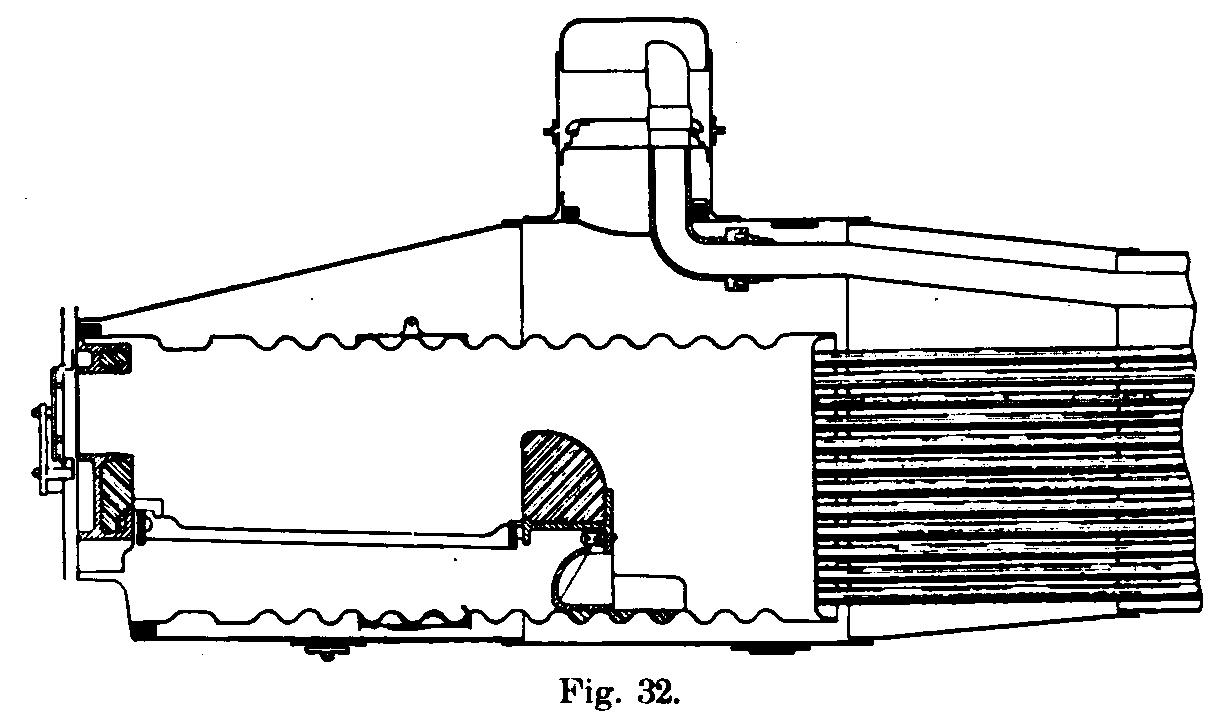

FIRE-BOX BOILERS - LOCOMOTIVE TYPE: HORIZONTAL, MANY SMALL FIRE TUBES, EXTERNALLY-FIRED Although vertical fire-tube boilers may be classed as fire-box boilers, yet the name fire-box boiler is usually applied to the locomotive type whether used with a locomotive or as a stationary boiler.

The usual form of horizontal fire-box boiler consists of a cylindrical shell, or barrel, partly filled with tubes, and a rectangular fire box. The shell is prolonged beyond the rear tube sheet to form a smoke box. The front ends of the tubes open into the firebox, while the rear ends open into the smoke box. The hot gases from the fire pass through the tubes to the smoke box and from thence to the stack or uptake. For locomotive work, there are a large number of small tubes (usually 2-inch), but for stationary work the tubes are larger and less numerous. The reason for this difference is that in the locomotive boiler a greater heating surface is necessary, and to obtain sufficient draft to burn the large amount of coal for this heating surface, the exhaust steam is turned into the smoke box. The blast of steam carries the heated gases up the stack and a fresh supply of air passes through the grate.

The cylindrical shell is joined to the fire box by riveting to a flanged ring or to a cone-shaped portion as in the vertical boiler. The fire box has a rectangular cross-section and usually a flat top.

Like the vertical boiler there is an inner and an outer fire box, the inner having the same shape as the outer, except that the top is flat. The external fire box is connected to the inner by short screw stays. The space between is called the water leg. The flat top is stayed by girders or crown stays. These are sometimes attached to the shell by sling stays. The lower portions of the tube sheets are held in place by the tubes; the upper portions are stayed by diagonal stays.

The chief differences in the various forms of locomotive boilers are the shape of the fire box and the location of the grate. Locomotive boilers are either straight top or wagon top. The wagon top boiler, see Fig. 28, has a cone-shaped portion by means of which the boiler is larger at the fire-box end. This construction

is to give a greater steam space. The increase in size of boilers has raised the top so high above the rails that the wagon top is not now used extensively; the straight top, see Fig. 29, is more common.

Belpaire Boiler.

The shell and fire tubes of this type of boiler are practically the same as in any other fire-box boiler; the peculiarity lies in the fire box. The inner and outer fire-box plates are horizontal at the top, and the sides of the outer fire-box are continued so that the space above the crown sheet is rectangular in section. The advantage of this construction is that the staybolts holding the crown sheets and side sheets can be placed at right angles to the sheets. This reduces the tendency to bending when under pressure.

Wootten Boiler.

In this type also, the fire box is the chief portion to be considered. The size of the locomotive fire box is limited. With older types the width was limited to less than three feet and the length to less than seven feet. This was because of the frames and the distance between the axles. By placing the fire box above the axles, the width was increased by an amount equal to the thickness of the frames or about seven inches, and the length increased to about eleven feet. By raising the fire box still more and placing it above the wheels, the width can be still further increased.

A broad, shallow fire box is required if anthracite coal is used. The Wootten fire box, shown in Fig. 30 and 31, is very wide and is placed on top of the driving wheels. Formerly, a combustion chamber was placed between the end of the grate and the tubes, but as it was found to be unnecessary, it is not now used.