Fire-Tube Boilers Manning Boiler Vertical Many Small Fire Tubes Fire Box

water and shell

FIRE-TUBE BOILERS MANNING BOILER: VERTICAL, MANY SMALL FIRE TUBES, FIRE BOX The Manning boiler is illustrated in Fig. 18. In order to get a large heating surface, it is made 20 to 30 feet high. It is, in general, similar to the upright boiler shown in Fig. 16. At the lower portion, the shell is of greater diameter than at the top in order to provide a large grate area. The inner fire box is stayed to the shell by screw stay bolts. As the fire box is surrounded by water and there are many long tubes there is a large heating surface. The tubes are arranged in concentric circles with a space for circulation in the middle.

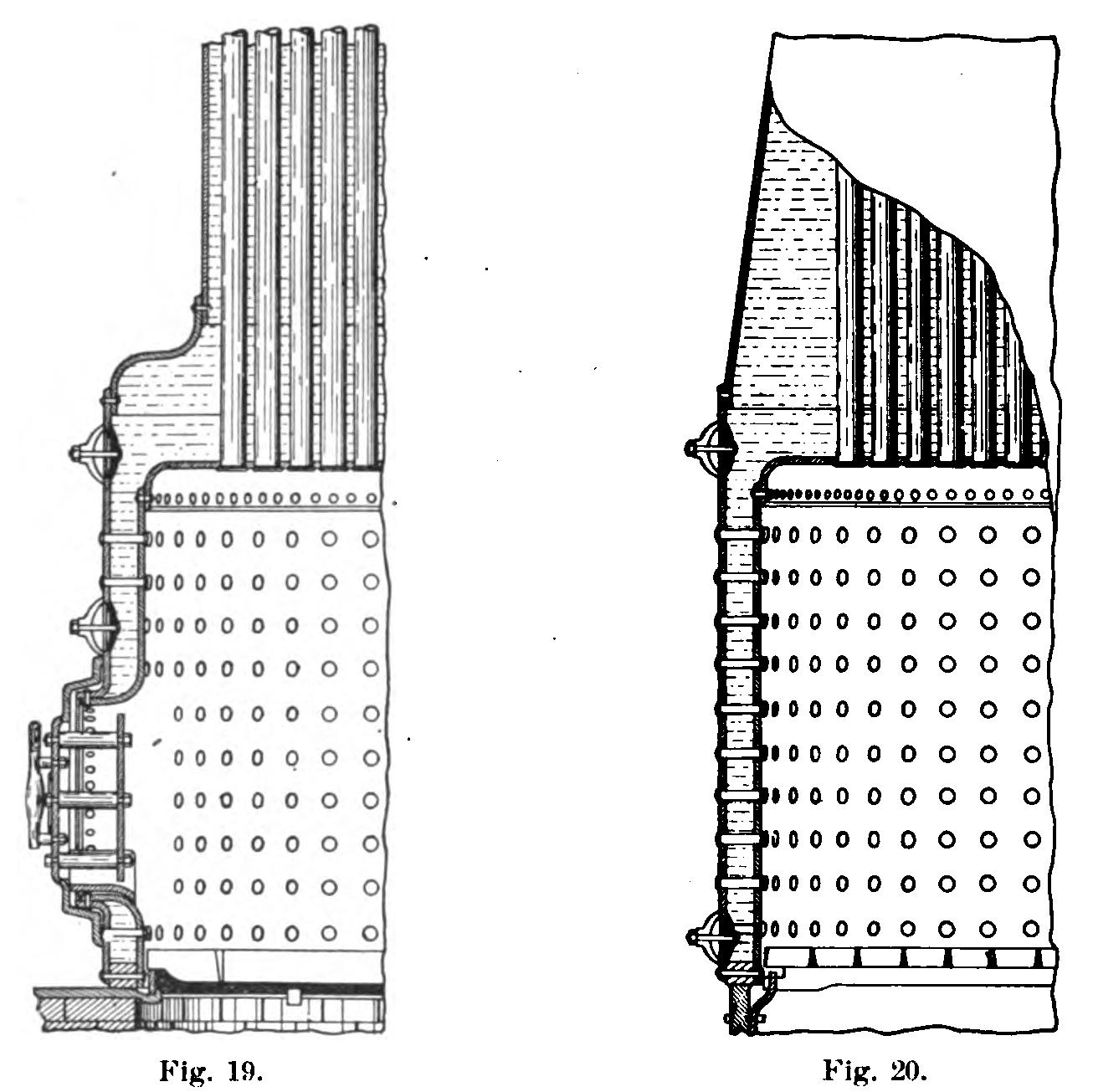

The external fire box is joined to the shell by a double flanged ring as shown in Fig. 19; or, by the cone-shaped section as illustrated in Fig. 20. The top edge of the internal fire box is riveted to the lower tube sheet which is flanged. The bottom of the inner fire box is connected to the outer shell by a welded ring (shown in section in Figs. 19 and 20) called the foundation ring. The water space between the inner and outer fire box plates, called the water leg, should be large.

This boiler is cleaned by means of handholes. They are placed in the shell plates near the lower tube sheet, in the external fire box just over the furnace door, and at the bottom near the foundation ring. As there are no manholes for cleaning, the boiler is suited to good feed water only.

The feed pipe enters the shell at the side near the middle of the water space, and extends across the boiler; it is perforated to distribute the water.

The heating surface consists of the inside of the fire box and the tubes up to the water level, and the tube sheet. That part of the tubes the water line is the superheating surface; that is, the heat from the gases passes through the metal of the tubes to the steam, thus raising its temperature without raising its pressure. Steam heated under these conditions is called superheated steam. In small vertical boilers this superheating surface is not desirable because the work of the small boiler does not require superheated steam and the tubes are likely to be burned by the intense heat. With the long tubes of the Manning, the gases are not as hot when they reach the top, and as this boiler is built in large powers (200 horsepower being common) the engines supplied are built for economy and require dry if not superheated steam.