Fire-Tube Boilers Return-Tube Boilers Horizontal Many Small Fire Tubes Internally-Fired

boiler and combustion

FIRE-TUBE BOILERS RETURN-TUBE BOILERS: HORIZONTAL, MANY SMALL FIRE TUBES, INTERNALLY-FIRED The boilers hitherto described are used mainly for stationary work, the exceptions being so few that they need not be even mentioned. Let us now discuss another modification of the fire-tube boiler—one that has been and is now extensively used in marine work. The parts of the return-tube boiler are essentially the same as those of flue boilers (Cornish and Lancashire) and the multitubular boiler. They are, however, arranged differently in order to be used on board ship.

The earliest forms

of marine boilers, working with pressures of 15 to 30 pounds per square inch, were square or box-shaped. They were economical and of convenient form for ships. When higher steam pressures became necessary, the flat surfaces required so much staying that they were abandoned and the cylindrical type introduced, as this form is the best of the practical shapes to resist internal pressure. The cylindrical form may not be as conveniently stowed aboard ship, bat it will stand much higher pressures. The cylindrical marine boiler is frequently built for 170 pounds per square inch.

The

boiler, shown in Fig. 21, combines the internal furnace flue of the Cornish type and the numerous small fire tubes of the multitubular. The cylindrical shell is made up of plates riveted together and to the flat ends of the boiler, which are flanged to fit the shell.

The furnace is cylindrical, three to four feet in diameter and about seven feet in length. The front end of the furnace flue is riveted to the front end plate, which is flanged for the purpose. The back end is riveted to the combustion chamber plates. Formerly, the flue was a plain cylinder, but as a plain cylinder, unless of small diameter, cannot stand much external pressure, it soon became necessary to strengthen it. This was done by means of the curved ring shown in Fig. 5 and other methods; but at present the corrugated flue is used, one form being shown in Fig. 6.

The grate is placed at about the center of the height of the furnace flue; the space above this grate is occupied by the fire and hot gases, below it is the ashpit. As will be seen from the arrows in Fig 21, the hot gases fill the space above the fire, the combustion chamber, the tubes and the uptake.

The combustion chamber in which the products of combustion are completely burned, is formed of flat and curved plates flanged at the edges and riveted together. The shape of the plates is shown in Fig. 21, which is a sectional view of a single-ended marine boiler. The back tube sheet forms the front of the combustion chamber. The space around the tubes, furnace flue, and combustion chamber is filled with water, the water level being six to eight inches above the top row of tubes. The space above the water level is called the steam space.

As the return-tube boiler has several flat surfaces, this type requires careful staying. The flat ends above the water level are prevented from bulging by long stay rods which are similar to those in the multitubular type. Below the water level, the furnace flue and the tubes aid in holding the flat plates together. In addition, a few of the tubes (shown by the heavier circles in Fig. 21) are made thicker so that a thread may be cut on the ends which are screwed into the tube sheets and held by thin nuts. The combustion chamber plates are stayed to the rear end plate and the shell by short screw stay bolts. The flat top of the combustion chamber is supported by girders or crown bars.

Number of Furnaces.

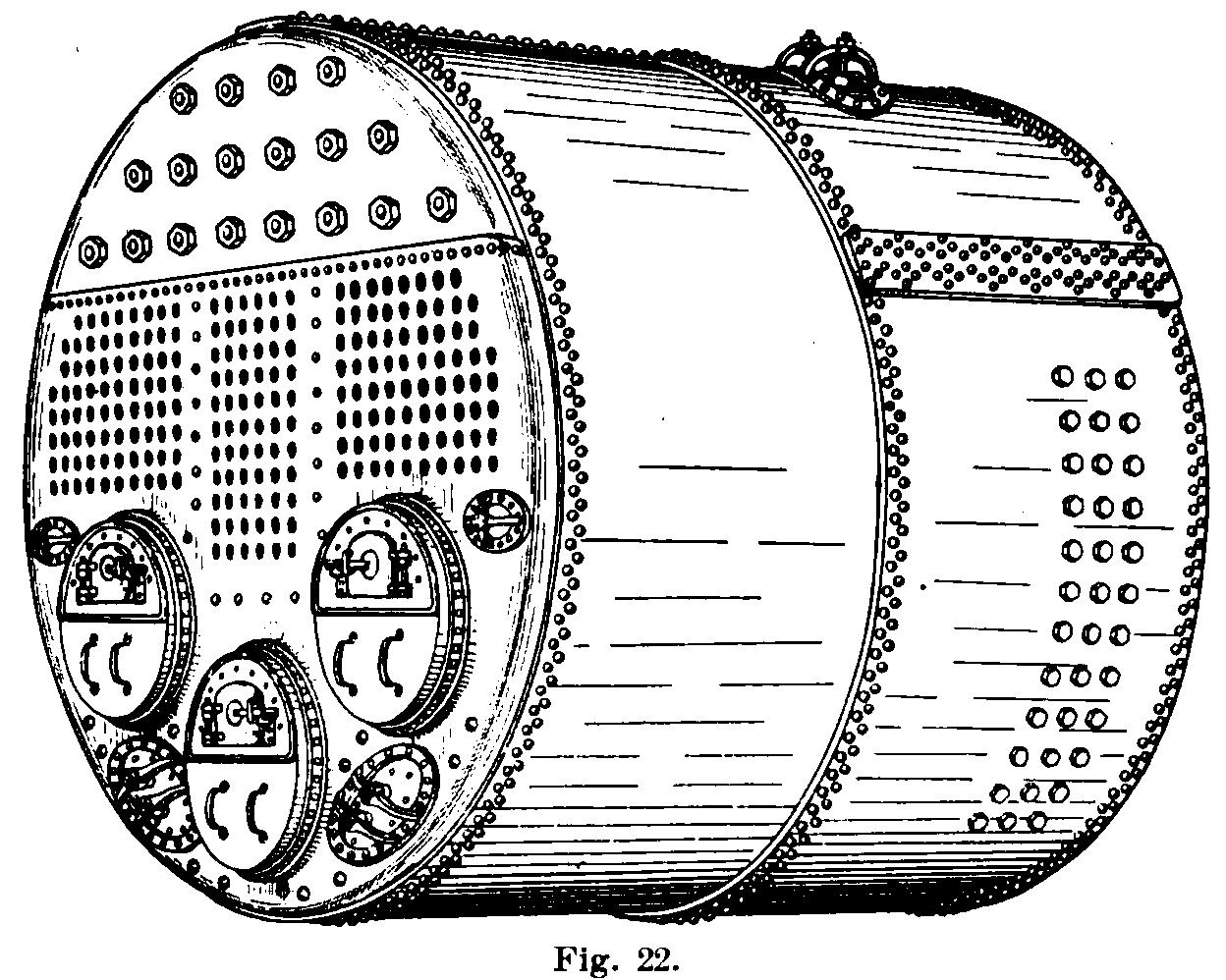

The boiler shown in Fig. 21 has only one furnace, but return-tube boilers frequently have two, three, or four furnaces.

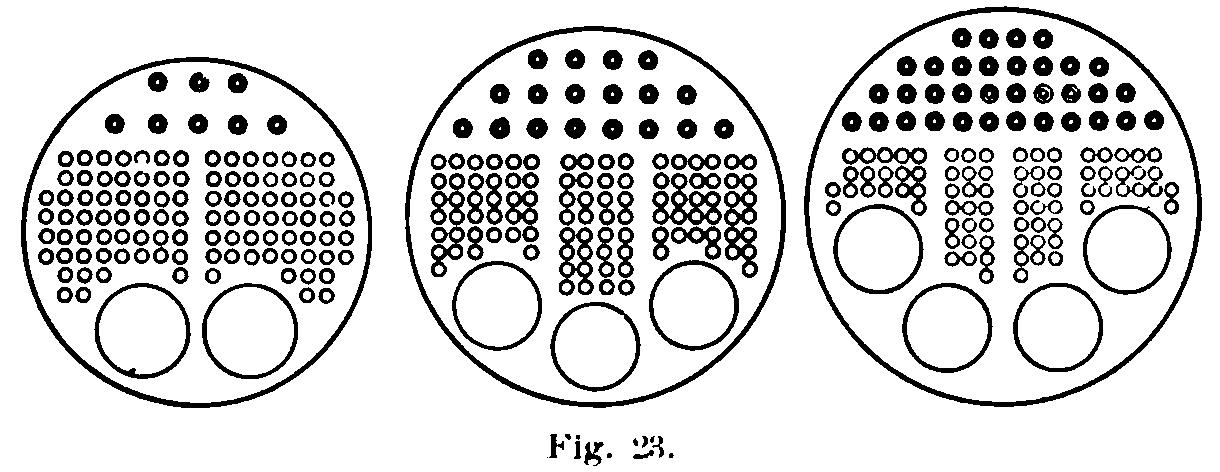

Fig. 22 shows a boiler with three furnaces. Large furnaces are more efficient than small ones because the grate area increases directly as the diameter, while the air space above the grate increases as the square of the diameter. The greater space aids combustion. The length of the grate bars is nearly constant for all sizes of flue because it is limited by the distance a fireman can throw coal. Furnace flues are usually from 36 to 54 inches in diameter. As the size of furnaces is fixed, the number depends upon the size of the boiler, for a large boiler must have a large grate area which can be obtained only by using several furnaces. The various arrangements are shown diagrammatically in Fig. 23.