Fire-Tube Boilers Upright Boilers Vertical Many Small Fire Tubes Fire Box

boiler and steam

FIRE-TUBE BOILERS UPRIGHT BOILERS: VERTICAL, MANY SMALL FIRE TUBES, FIRE BOX Upright boilers are used when floor space is valuable and there is sufficient height. In small sizes, they are used for hoisting engines, pile driving, for supplying steam for pumps, and similar work; in large sizes when it is necessary to have a powerful battery in a small space. In general they are not as economical as the horizontal multitubular boiler unless they are carefully designed and of considerable height. If the tubes are short, the hot gases escape before they give up much of their heat.

One of the simplest forms of upright boiler is shown in Fig. 15. It has a cylindrical shell with a large fire box at its lower end. This fire box is formed by the inner cylinder which is fastened to the outer shell by short screw stay bolts as shown. A flanged ring connects the fire box with a large flue which conducts the hot gases away. The necessary handholes, gages, safety valves, etc., are provided. This form is not economical but is used on account of the little attention required.

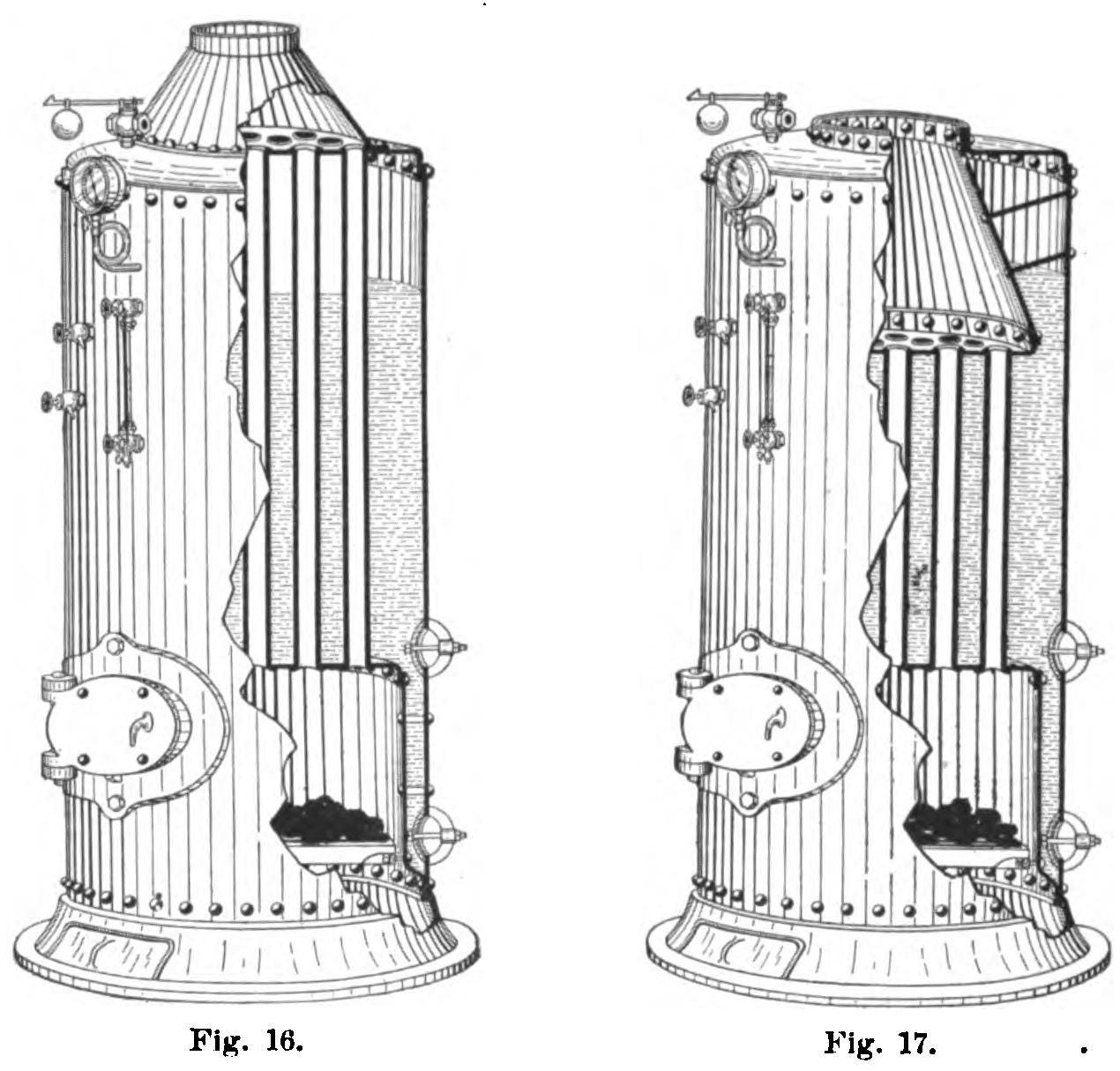

More economical forms of the small upright boiler are illustrated in Fig. 16 and 17. The boiler shown in Fig. 16 is a common form; externally it is like the boiler represented by Fig. 15, but within, it has a somewhat different construction. It resembles a multitubular boiler placed on end. The fire box is made of an inner cylinder stayed to the outer. The top of the fire box, called the lower tube sheet, is connected to the upper head by tubes, through which the hot gases pass to the smoke pipe. It will be readily seen from Fig. 16, that the 'upper ends of the tubes are surrounded with steam while the lower portions are covered with water. As steam is a poor conductor of heat, the ends of these tubes are liable to injury from overheating.

In the class of boiler shown in Fig. 17 the upper ends of the tubes are below the water level, thus avoiding the weakness described in connection with Fig. 16. The upper tube sheet is submerged and is flanged and riveted to the frustum of the cone which forms the smoke box. The chief defect in this boiler is that the lower part of the cone is often placed too near the shell; this is done to admit more tubes. This construction restricts the space so much that there is not sufficient room for the steam to rise as it is formed on the tubes. The cone, which is subjected to external steam pressure, is likely to be weak and is usually carefully stayed.

These small upright boilers require no brick setting, as the fire box is within the boiler and the cast-iron foundation forms the ashpit.