Horizontal Water-Tube Boilers - Heine Water Tubes Nearly Horizontal Steam and Water Drum Parallel to Tubes Straight-Tube Single-Tube Non-Sectional

leg and mud

HORIZONTAL WATER-TUBE BOILERS - HEINE: WATER TUBES NEARLY HORIZONTAL, STEAM AND WATER DRUM PARALLEL TO TUBES, STRAIGHT-TUBE, SINGLE-TUBE, NON-SECTIONAL Construction. The Heine water-tube boiler is not a sectional boiler. Instead of being expanded into small headers grouped to form a boiler, all the tubes are expanded into the inside plates of a water leg at each end. The construction of this water leg is shown in Fig. 50. It is composed of two parallel plates flanged and riveted to a butt strap. The plates are strengthened by short hollow screw stays similar to those used in the water-leg construction of fire-box boilers. At the top, the water leg is curved and joined to the steam and water drum by riveting. Opposite each tube is a hand hole for cleaning or replacing a defective tube.

Circulation.

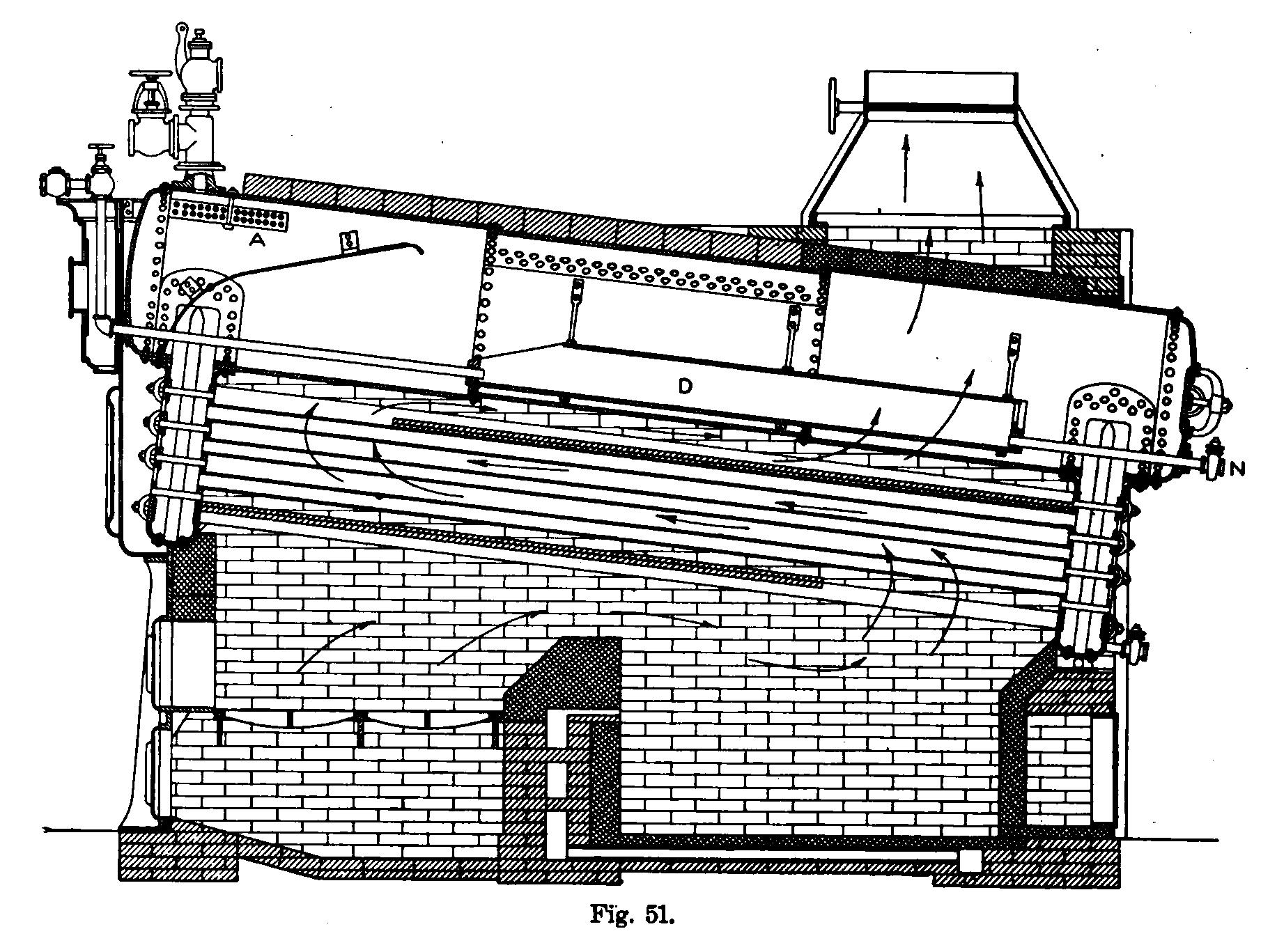

The feed water enters at the front of the steam and water drum and flows into the mud drum D, from which it passes to the rear header with much less velocity. The water is warmed while passing through the pipe leading to the mud drum, and as it flows slowly through the mud drum it deposits its sediment. The accumulated sediment is blown off by means of the blow-off pipe N. The water, as it becomes heated in the mud drum, rises and passes to the front of the mud drum, from which it flows in a thin sheet to the rear of the steam and water drum and to the rear water leg. From- the rear water leg, it enters the tubes in which it is partially converted into steam. The mixture of steam and water enters the higher end of the drum from the water leg, and as there is but a thin layer of water in the steam and water drum, the steam readily rises through it. A deflection plate prevents water from being carried to the perforated steam pipe A.The flow of hot gases from the fire is directed by light tile placed on the upper and lower rows of tubes as shown in Fig. 51. The hot gases flow nearly parallel with the tubes instead of across them as in the Babcock and Wilcox.