Horizontal Water-Tube Boilers - Niclauss Water Tubes Nearly Horizontal Steam Drum Horizontal Straight-Tube Double-Tube Sectional

tube and header

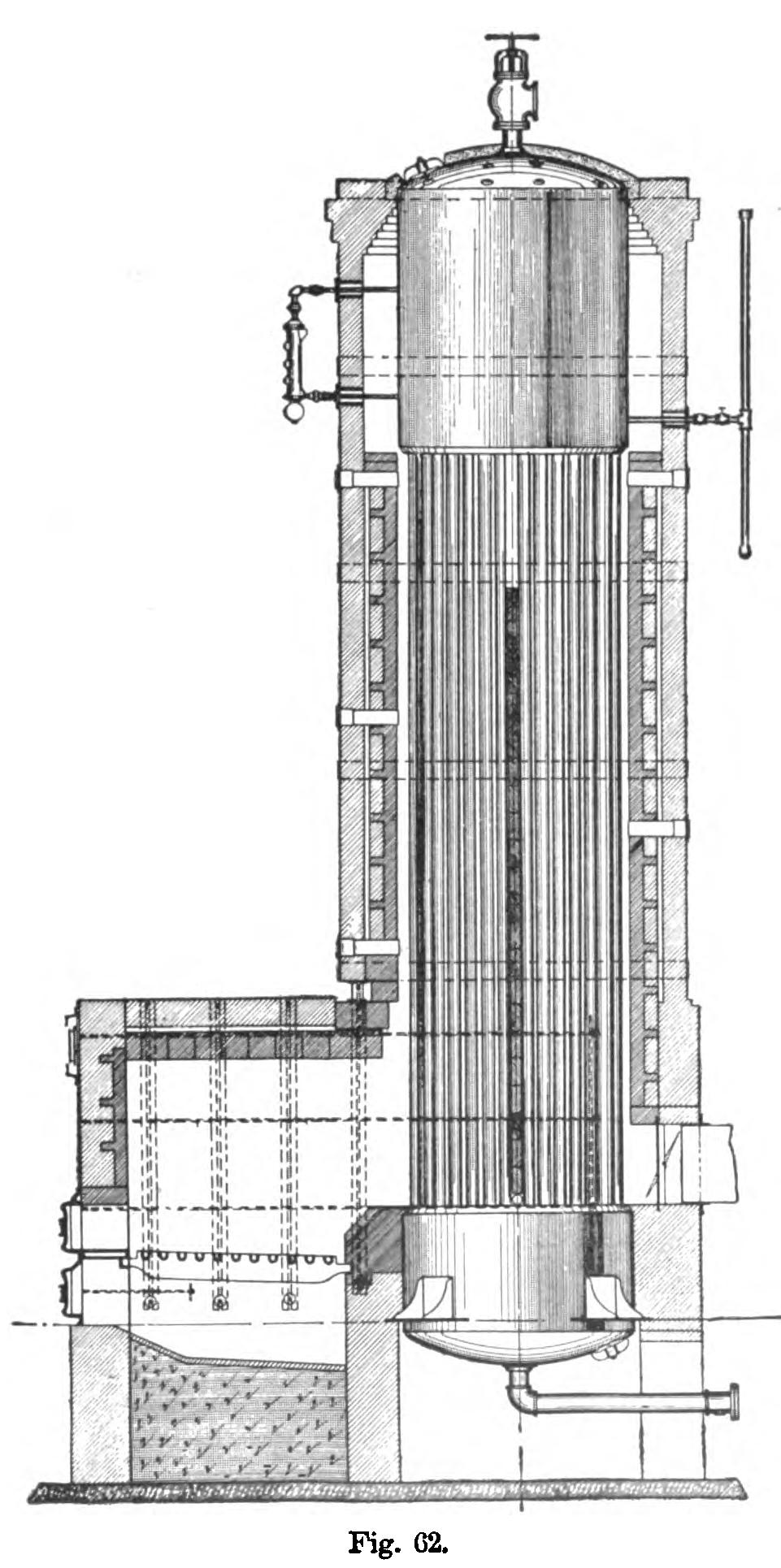

HORIZONTAL WATER-TUBE BOILERS - NICLAUSS: WATER TUBES NEARLY HORIZONTAL, STEAM DRUM HORIZONTAL, STRAIGHT-TUBE, DOUBLE-TUBE, SECTIONAL This boiler differs essentially from those already described in that it is of the double-tube type. In general, it consists of a number of elements which form a vertical header, to which tubes are connected. The tubes are set at an angle of about 6 degrees to the horizontal. Above the elements is a transverse steam and water drum which is in communication with the headers. The general arrangement of parts is shown in Fig. 59.

Construction.

The interesting features of this type of boiler are the design and construction of the tubes and headers. To increase the circulation the principle of the "Field" tube is employed. In this construction, the outer, or generating, tubes (3-1/4 inches in diameter) are closed at one end. Each generating tube contains an inner circulating tube which is 1-19/32 inches in diameter.

This tube is open at both ends. The closed ends of the generating tubes are supported by resting in holes in a plate or rack at the rear of the boiler. The forward end of the circulating tube is attached to a cap which screws into the outer end of the generating tube. A recess in this cap provides a bearing for an arch bar which spans two tubes, keeps them in place, and is itself secured by a nut on a bolt which is screwed into the header. See Fig. 60.

The front end of the generating tubes is of peculiar shape. •To allow the water to enter the circulating tubes, and to fasten the tubes to the header without expanding them, each generating tube is provided at the open end with two cone-shaped portions; these are about eight inches apart. The first cone fits into a taper hole flanged outward in the front face of the header, and the second cone fits a similar hole in the rear face of the header. Both the holes and tubes are ground to the same size and taper. About midway between the cones, a third expanded portion occupies the tube hole in the diaphragm or middle plate of the header. See Fig. 60. The portion of the tube within the header is called the "lantern". At this point the tube is cut away so that water may freely enter the tube, the openings being above and below. In Fig. 60, the upper tube is in its normal position, but the lower tube has been turned through 90 degrees to show the construction.

To stand high steam pressures, the elements of the headers are made of wrought steel and are sinuous in shape. Fig. 61 shows the shape of the header and the positions of the tubes.

Each element contains 24 tubes in two vertical rows of 12 each In the middle of the headers, there is a diaphragm for dividing the interior. The front passage serves as a "downcomer" for the water, and the rear is the or riser, for the mixture of steam and water.

The lower ends of the headers are closed, and the upper ends flanged to connect with the steam and water drum, which is 42 inches in diameter.

Circulation. Fig. 60 gives an idea of the direction of circulation. Water from the drum descends in the front compartment of the header, flows into the circulating tubes, which communicate with the front compartment only, and after flowing the length of the circulating tubes, enters the generating tubes. The water then comes back through the annular spaces in the generating tubes to the rear compartment of the header, because the generating tubes communicate with, the rear compartment only; while in the annular space it is partially evaporated. The mixture of steam and water then rises to the drum.