Peculiar Forms of Fire-Tube Boilers

boiler and water

PECULIAR FORMS OF FIRE-TUBE BOILERS Return Tubular as Stationary. Boilers of the form shown in Fig. 34 resemble the locomotive, fire-box type, but in addition have return tubes. The hot gases reach the uptake by means of these tubes instead of passing to the chimney from the smoke-box end. Thus they combine the advantages of the fire-box type and the return-tube type without the brick furnace. The water surrounds the furnace on all sides except the front. They are built in sizes from 12 to 70 horse-power. As Fig. 34 shows the construction so clearly, further description is unnecessary.

The Cochrane Vertical Boiler

is somewhat like the returntube boiler in point of arrangement of heating surface. This boiler is shown in section in Fig. 35. The hot gases pass from the furnace to the combustion chamber, then through the tubes to the uptake. The heating surface consists of tubes and the plates of the fire box which is surrounded by water except the bottom. The crown of the boiler and of the fire box, being hemispherical, require no staying. The hemispherical crown also allows a large steam space. The flat plates (the tube plates) are held together by the tubes.

The Shapley

shown in Fig. 36, may be called a return-flue vertical boiler. The upper portion is a reservoir for water and steam and the lower contains the fire box. The crown sheet of the fire box is stayed to the top by through stays. The hot gases from the fire rise in the fire box, pass through short horizontal tubes to an annular space. This annular space is connected to the flue at the base by vertical tubes passing through the water space.

This boiler has a large combustion chamber; the fire box is surrounded by water, and the crown sheet and tubes are removed from the intense heat of the fire. This arrangement increases the heating surface, allows complete combustion and results in a durable boiler. The base is partially filled with water so that any sparks carried over will be quenched.

This boiler resembles the through-tube internally-fired boiler (see Fig. 27) in that the fire is within a corrugated flue and the tubes lead from this fine to the rear of the boiler.

The Robb-Mumford boiler consists of two cylindrical drums or shells, connected at each end by a neck. See Fig 37. The upper drum is a steam and water drum, the water level being at about the middle. The lower shell is larger and is inclined about one inch in twelve to increase the circulation, and facilitate wash. ing out. In this lower shell is the corrugated flue containing the grate. The fire tubes nearly fill the remaining portion of the shell as shown.

The furnace, in which the coal is burned, is surrounded by water; the hot gases pass through the tubes to the rear, return between the lower and upper shells and escape to the chimney from the front of the boiler. The steel casing keeps the gases in contact with the drums. The water circulation is shown by the arrows. The mixture of water and steam enters the upper drum; the steam here separates from the water which flows down the neck at the forward end. A semicircular baffle plate directs this water around The furnace to the bottom. The feed water enters at the rear of the steam and water drum.

As compared with the multitubular boiler one can readily see that the drums can be made much thinner on account of the small diameter. The tubes are short, straight, and easily cleaned. The internal furnace does away with much of the loss from leakage. As the water is well subdivided, steam can be raised rapidly and there is little danger of a disastrous explosion.

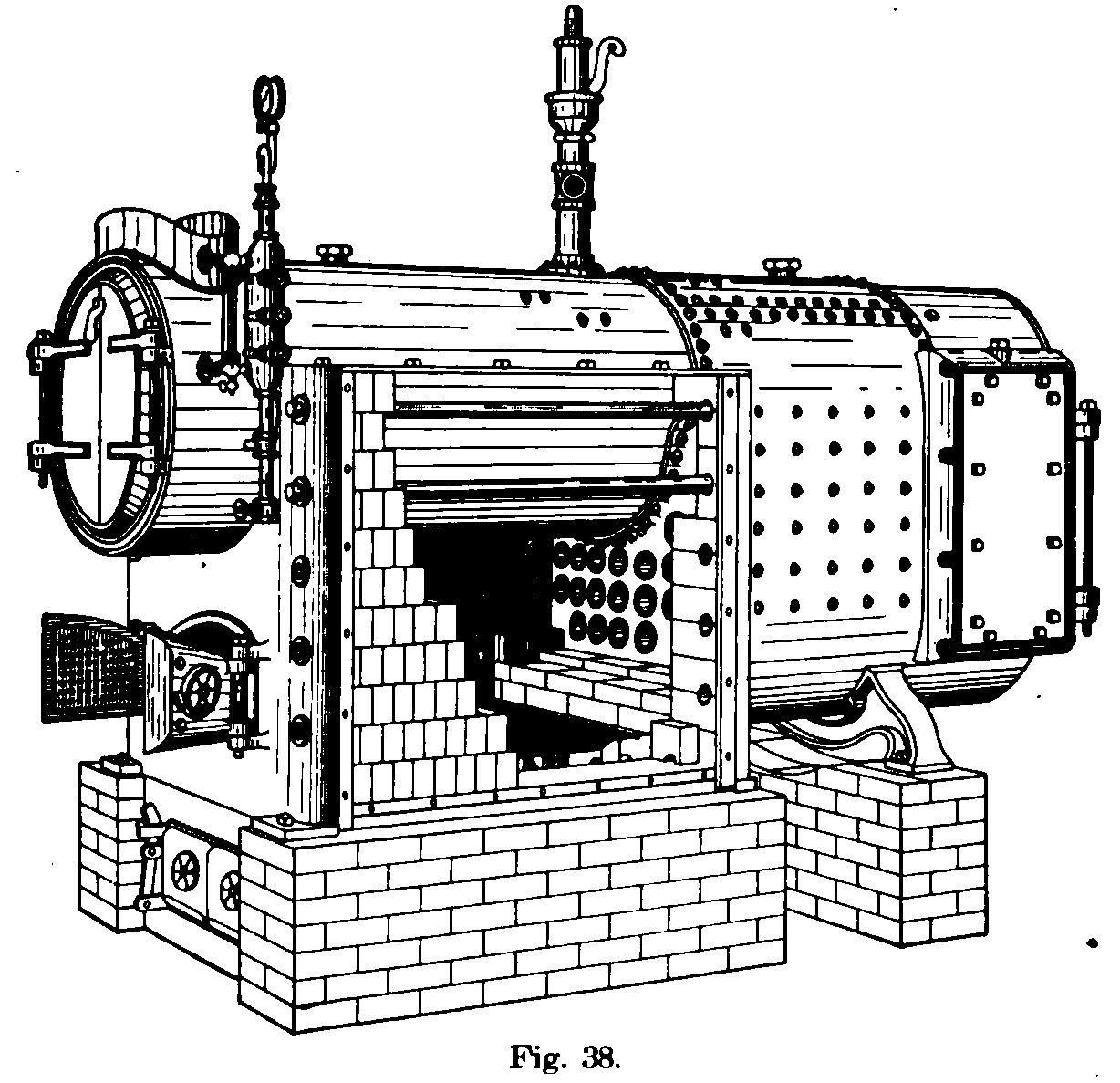

Directurn.

The Begg's "Directurn" boiler (Fig. 38) is, in brief, a horizontal, externally-fired, multitubular boiler in which tubes conduct hot gases through the space behind the bridge.

This boiler consists of a shell partly filled with 3-inch tubes. The rear of the furnace is a throat sheet in which 4-inch tubes are expanded. The other ends are expanded into the rear end plate which is made large enough for the purpose. The boiler is encased in steel plates lined with fire brick which is held in place by rods passing through the notches as shown. The manhole for entering the boiler is placed in the front head instead of iii the shell as is frequently done.