Peculiar Forms of Vertical Water-Tube Boilers - Harrison Sectional Hollow Cast-Iron Spheres Instead of Tubes

units and boiler

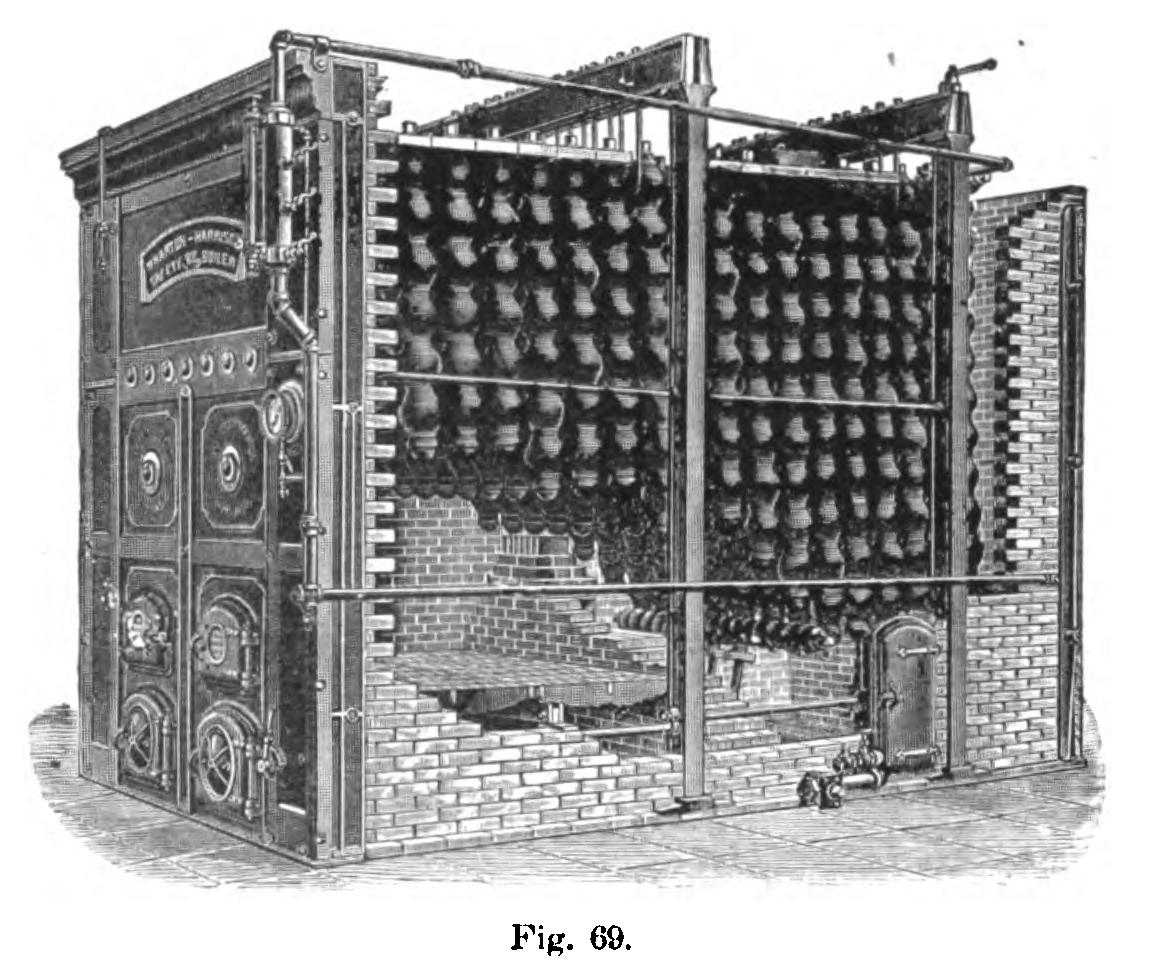

PECULIAR FORMS OF VERTICAL WATER-TUBE BOILERS - HARRISON: SECTIONAL, HOLLOW CAST-IRON SPHERES INSTEAD OF TUBES All boilers thus far described have employed tubes as a means of dividing the water into small masses in order to make the heating surfaces more effective. In the Harrison Safety Boiler (Fig. 69) tubes are not used; instead, the water is contained in hollow cast-iron spheres, called units. These units, see Fig. 68, are arranged in vertical rows, called slabs, which are suspended side by side, about one inch apart, from an iron framework. The brickwork setting is merely a covering to keep the hot gases in contact with the units; it does not support the boiler, and can be repaired without disturbing the units.

The use of units in place of tubes combines great strength and a large heating surface. They are strong because small and spherical and on account of the division of the water into small masses, the heating surface is effective. The units are held together by long bolts which pass through the centers as shown in Fig. 68. The machined faces make a steam-tight joint without packing. This boiler requires the same fittings as other boilers.

The great advantage of this boiler is safety. From the construction, it is apparent that rupture cannot extend beyond the unit; thus disastrous explosions cannot occur. They are claimed to be durable, economical, rapid steamers, and easily handled. The capacity can be increased by merely adding more slabs.