Boiler Accessories Blow-Out Apparatus

bottom and valve

BOILER ACCESSORIES: BLOW-OUT APPARATUS Boiler feed-water, if taken from rivers or ponds, is likely to contain vegetable matter as well as solid materials. The vegetable matter will usually float to the surface, while the solids will collect at the bottom. To keep the boiler clear of such sediment; it is necessary to provide two blow-ouls—a surface blow-out, to take care of what rises to the top; and a bottom blow-out, to take out the sediment that collects at the bottom of the boiler. The surface blow-out usually consists of a dish or funnel-shaped receptacle set with its face vertical, as shown in Fig. 49. When the water-level is in line with this blow-out opening, the opening of the valve at the bottom will skim the impurities from the surface of the water quite readily. Oil may get' into the boiler through the feedwater, and a considerable portion of it can be removed in this manner.

The bottom blow-out consists merely of a pipe leading from the bottom of the boiler outward. Both these blow-outs may be connected into one outlet.

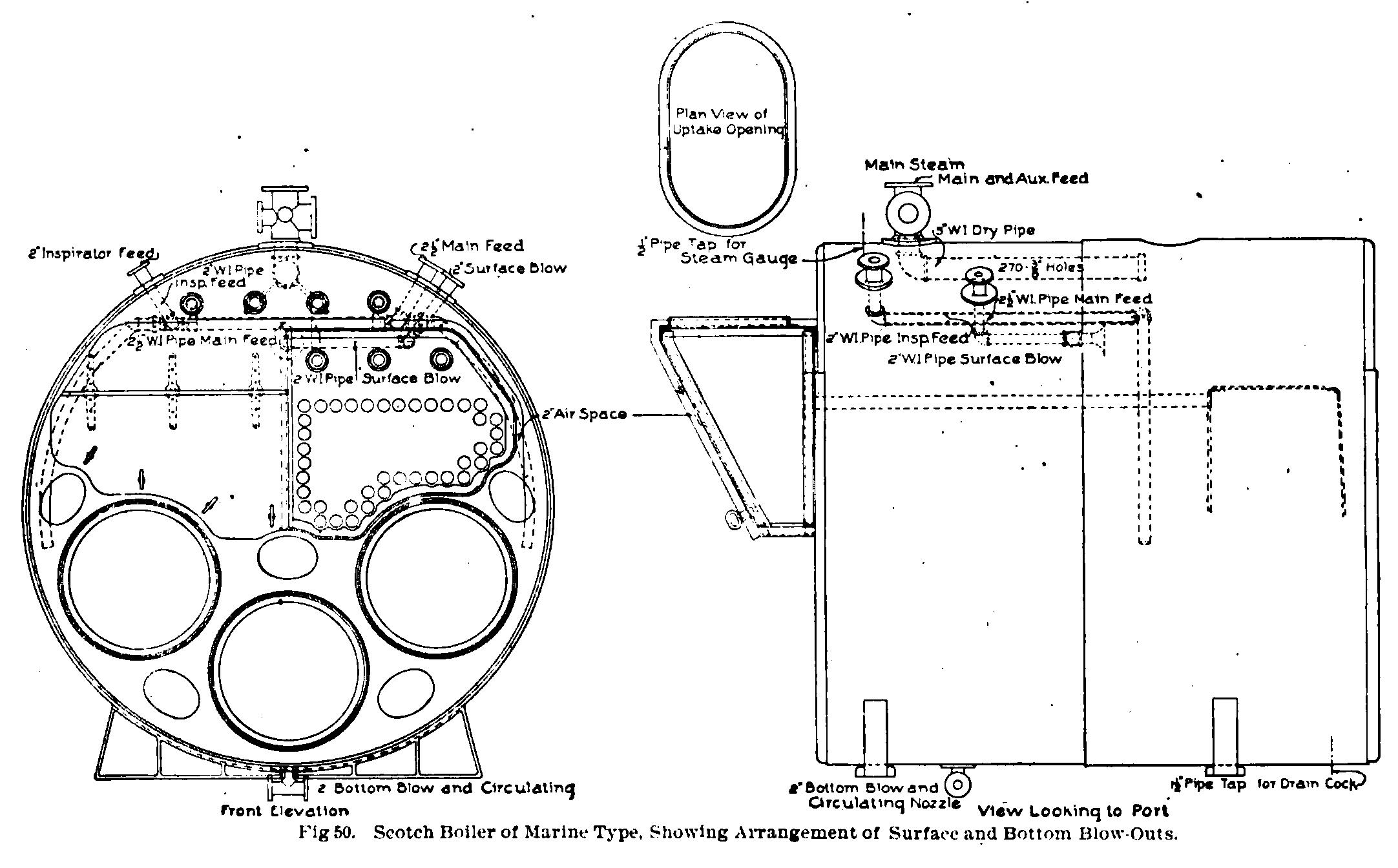

In water-tube boilers a mud-drum is usually installed, which readily collects the solid matter, and the bottom blowout is then connected with this mud-drum. Fig. 50 shows an arrangement of surface and bottom blow-outs as usually installed on a Scotch boiler of the marine type.

If the feed-water contains which may frequently happen in marine practice, it is necessary that the boiler should frequently be blown out in order to remove the excess of salt. The density of the boiler water, if salt feed is used, should be carefully determined by a salimeter. The loss due to this frequent blowing out is considerable, as a large amount of heat is necessarily wasted ; but it cannot be avoided, except by the use of fresh water, which sometimes may be impossible at sea.

The blow-out pipe leading from the bottom of an externally-fired boiler through the brick setting, if not properly protected, may be burned off, owing to the heat of the fire. This pipe is frequently covered with asbestos or other material; but it can be best protected by the means shown in Fig. 51. A pipe connected to the boiler slightly below the water-level, runs out through the brick setting and connects into the main blow-out pipe. This causes a circulation of water continually to pass through the system, and prevents destruction of the blow-out pipe. When it is necessary to use the bottom blow-out, the valve if is closed, and the blow-off valve B is opened; otherwise, B is closed, and :1 is open while the water circulates..

The blow-out pipe is usually shut off by a cock, which, although not so easily operated as a valve, is more trustworthy. Frequently both a cock and a valve are provided. Should a small particle of sediment lodge on the valve-seat, it would be impossible to close the valve tightly, and a considerable leakage would result, while an inspection of the valve would not indicate whether it were completely closed or not. But a glance reveals the fact whether or not a cock is tightly closed. The cock is likely to stick because of corrosion or unequal expansion, hut, if frequently opened, this difficulty is not of great weight. The plug and casing of the cock should not he mule of the same material, as in that ease they will more readily stick if the cock remains closed any length of time.