Boiler Accessories Boiler Setting

walls and foundation

BOILER ACCESSORIES: BOILER SETTING The setting for a stationary boiler consists of the foundation and as much of the furnace and flues as is external to the boiler shell. Some internally-fired boilers—the "Lancashire," for instance—have flues in the brick setting. The whole furnace and sometimes the flues, as is the case with the plain cylindrical boiler, are in the setting. Vertical boilers have simply a foundation; and locomotive boilers have no setting, since they are supported by the frames of the engines. Marine boilers are usually placed on saddles, which are built into the framing of the vessel.

In setting a boiler, there are three principal requisites that should be kept in mind: 1. A stable support or foundation for the shell, so arranged as to allow for proper expansion of the boiler. 2. Properly arranged spaces for both furnace flues and ash-pit. 3. A covering which will prevent loss of heat by radiation, and which will not allow moisture to accumulate in contact with the plates.

There are two principal methods for support—by brackets riveted to the shell plates, and by suspension from overhead girders by means of hooks, rings, etc. In any case the supports should be so arranged that each shall bear its proper proportion of the load and at the same time allow for expansion. If the boiler is short, brackets are generally used; while for long, plain cylindrical boilers the girder method is the more common. If a very long, cylindrical boiler is supported only at each end, the great weight between the two supports is likely to cause bending and an excessive strain on the middle plates, tension in the bottom plates, and compression in the top plates.

The first requisite for a setting is a good foundation. If the ground is firm and favorable to a solid foundation, the excavation need be only three or four feet below the level. If it is soft, the excavation should be deeper, and the extra depth filled in with broken stone mixed in with cement, gravel, etc.; or, for very heavy work, piles may be driven. The first course of the foundation should be large stones laid in cement; upon this stonework the walls may be built, either of stone or brick, to within about six inches of the floorlevel; and above this, brick should be used.

Sometimes the bed is made of concrete about two feet in thickness. If the soil is very firm, a foundation of large stonework about three feet wide may be built under the side, middle, and end walls only.

In determining the area of the bed, the weight that is to be put on each square foot should be estimated carefully. With ordinary condition of the soil, this should not exceed 2,000 pounds. For greater weights, special construction must be used.

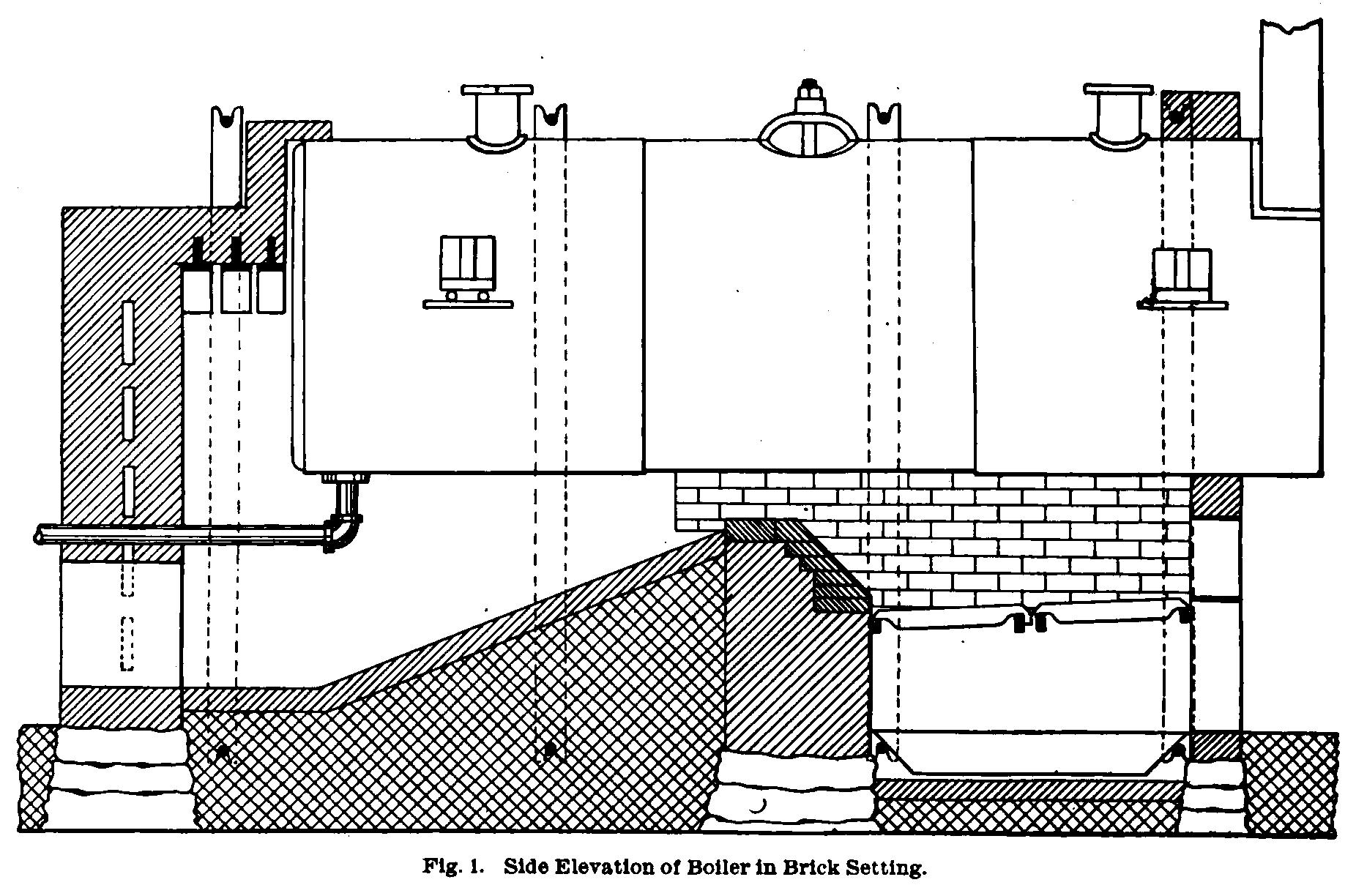

The supporting and enclosing walls are built upon the foundation, with the outer walls at the sides and rear double, the space between, usually about two inches, being an air-space insulation to prevent loss of heat. Projecting bricks, which extend from the outer until they just touch the inner wall, allow for expansion without decreasing the strength of the inner wall. The side walls are strengthened by buckstays or binders, which are kept in place by long bolts, secured by nuts on each end. Fig. 1 shows a boiler in the brick setting, supported by brackets, the front brackets resting on iron plates which are built into the walls; the rear brackets, being supported by rollers, are free to move as the shell expands. If designed for anthracite coal, the distance between the shell and the grate-bars is about two feet; for softer coal, this distance is increased a few inches.

The furnace is lined with firebrick, both front and sides; and sometimes portions back of the bridge, as well as the bridge itself, may thus be protected. The space between the bridge and the shell is from 6 to S inches, which brings the hot gases into close contact with the boiler before they enter the combustion chamber beyond, the rear and side walls being built a little higher than the top row of tubes. The fire-line must not be carried above the water-line; if it is, the intense heat is likely to injure the shell-plates. Never expose any part of the boiler not covered by water to the flames from the furnace. The side walls are built about the same height as the rear walls. The space at the rear is bridged over and stiffened by T-irons. In order to increase the heating surface, the top is arched so that the hot gases will pass over the steam space before they enter the chimney.