Boiler Accessories Steam and Vacuum Gauges

pressure and gauge

BOILER ACCESSORIES: STEAM AND VACUUM GAUGES The steam pressure in the boiler is measured in pounds per square inch. When we say the boiler is working or steaming at 80 pounds' pressure, we mean that the gauge pressure is 80 pounds; that is, the pressure in the boiler is 80 pounds above atmospheric pressure. It could be measured by a water or mercury column; but, as these would need to be very high to measure the pressures used at the present day, they are not practicable, and so a spring-pressure gauge is used instead.

The dial gauge, now used almost universally, was invented by M. Bourdon. It is designed in accordance with the principle that a flattened, curved tube dosed at one end tends to become straight when subjected to internal pressure.

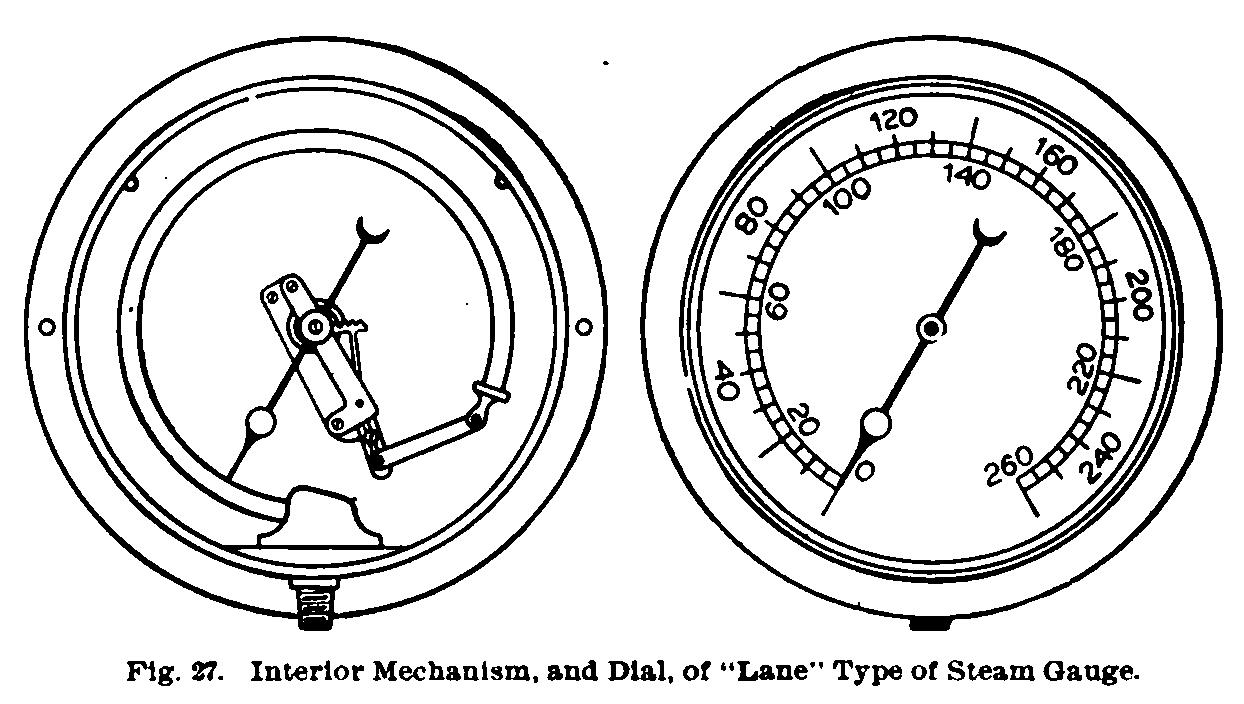

The tube, which is usually oval in section, is bent into the arc of a circle as shown in Fig. 26. One end is fixed, and is in communication with the boiler. The other is closed and free to move. By means of levers, a curved rack, and a pinion, the motion of the free end is multiplied and indicated by a needle, which is attached to the pinion. The needle moves over a dial which is graduated to agree with a mercury column, or with a standard gauge. The back-lash of the levers is taken up by a hair spring. Fig. 27 shows the interior and face of a Bourdon steam gauge manufactured by the American Steam Gauge Company.

Fig. 28 shows the exterior and interior of a steam gauge with a light tube for low pressures; the face of the dial is graduated corresponding to the mercury column. The only difference between this gauge and the vacuum gauge, is that in the latter the curved tube is turned in the opposite direction so that the needle will move clockwise with a decrease of pressure.

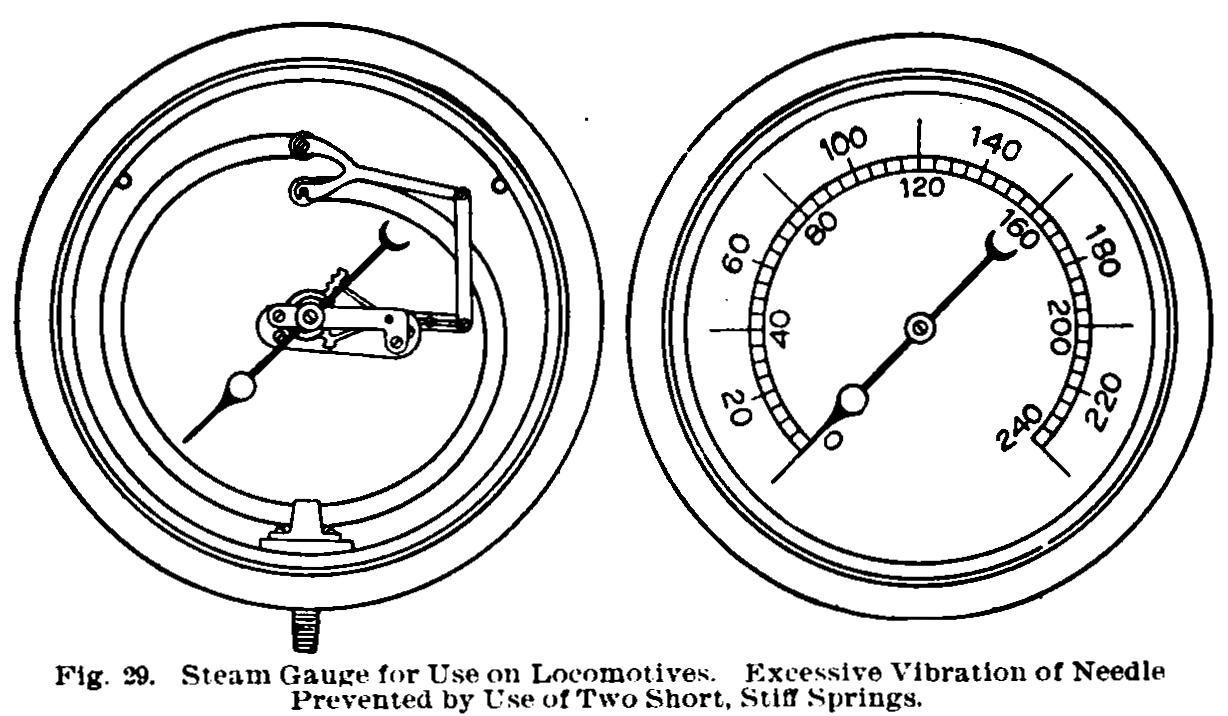

On account of the jarring, the gauge for locomotives must be very strong. To prevent excessive vibration of the needle, two short, stiffer springs are used, as shown in Fig. 29.

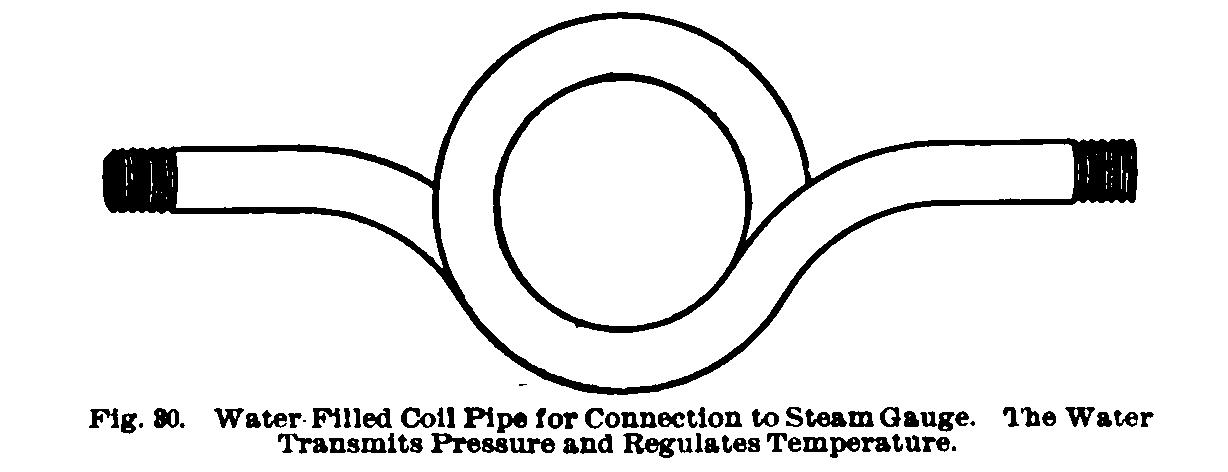

Sometimes two pressure gauges are fitted to a boiler, one indicating the working pressure, and the other graduated to about twice the working pressure. The latter is useful in testing the boiler under water pressure, and also serves as a cheek on the other. The pipe which connects the pressure gauge to the boiler should have bends in it near the gauge. These bends—or, better, a coil pipe, as shown in Fig. 30— are filled with water, which transmits pressure and keeps the spring at a nearly constant low temperature. Gauges should be placed where the water in the coiled pipe will not freeze; also, the gauge should not be exposed to strong heat. In order that the gauge may be removed from the boiler for examination, repairs, or calibration, when the boiler is under pressure, the connection should be provided with stop-cocks..

In a battery of boilers, each should have its pressure gauge, which should be connected directly to the boiler, not to the steam pipe.