Boiler Accessories Tube-Stoppers

stopper and tube

BOILER ACCESSORIES: TUBE-STOPPERS It frequently happens, when tubular boilers are under pressure, that leaks occur in the tubes through pitting, defective welding, or the development of cracks. Formerly, when this occurred, the fire was drawn, and the ends of the tube plugged with hardwood bungs driven hard home or with iron plugs calked in. With high pressures, such procedure is impossible. Tube-stoppers used for high pressure are joined together by a tie-bar of some sort. They are usually wedge-shaped; and the tie-rod, passing through the stopper at one end, with a plug at the other end, can be screwed hard up.

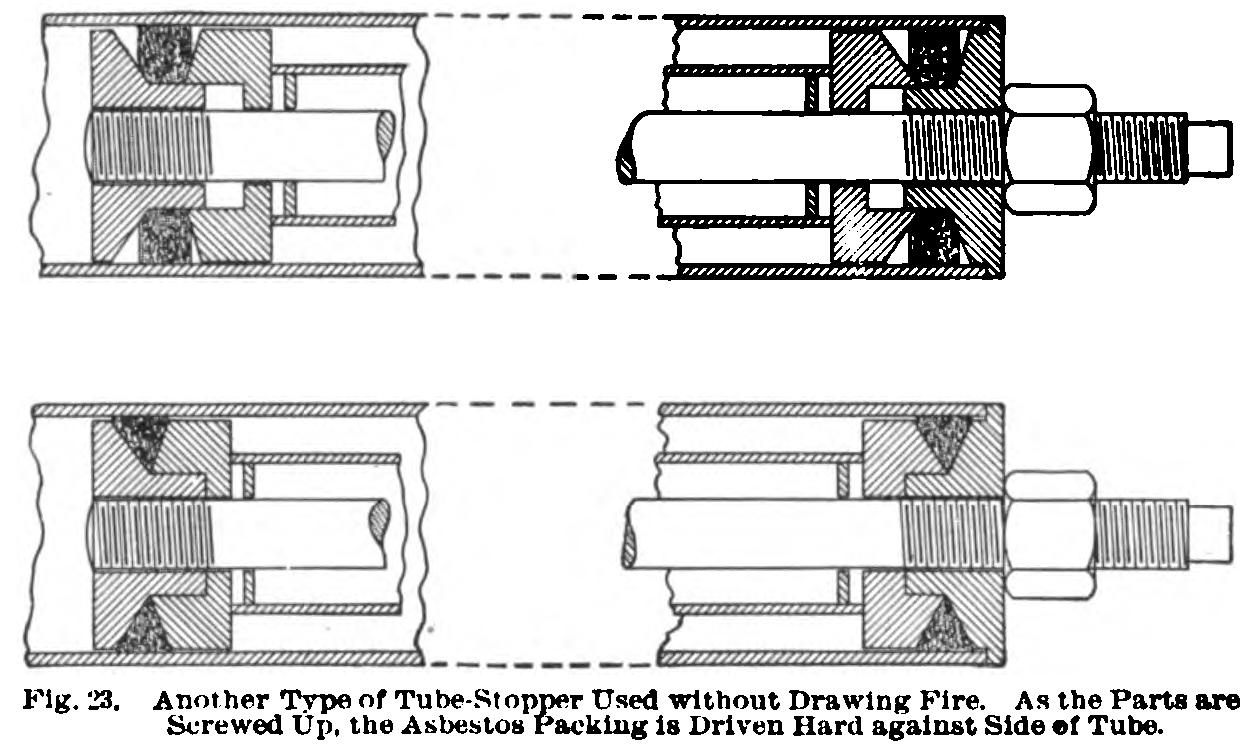

The simplest form of stopper has to be inserted from the rear, and necessitates drawing the fire; but Fig. 22 illustrates a stopper which can be inserted without drawing the fire. At the end of the rod is hinged a folding bung, which can be passed through the tube and which opens out in the combustion chamber before being pulled into position. At the smoke-box end .of the boiler, an india-rubber washer, pressed between two pieces of metal, affords temporary protection while the plug is being put in position. The stopper can then be screwed up tightly with a handle provided for that purpose.

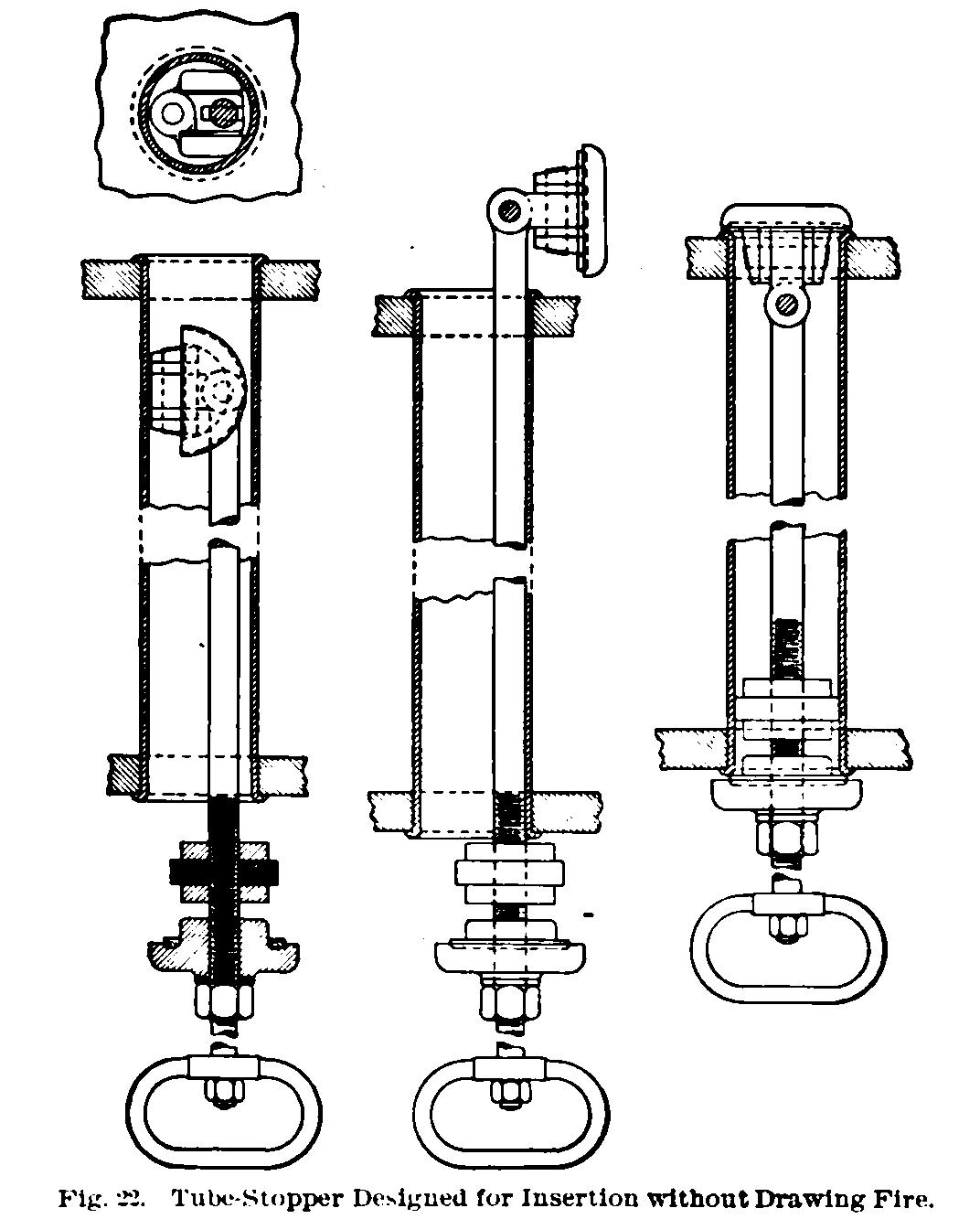

Fig. 23 illustrates another arrangement which can be inserted in the leaky tube without drawing the fire. The ends, being in the form of stuffing glands, press an asbestos packing hard against the side of the tube.