The Basis for Grades of Lumber Grading

cut and defects

THE BASIS FOR GRADES OF LUMBER GRADING Lumber is separated into grades on the basis of the defects which it contains; and the first step in the formulation of a grading system is to define the admissible defects. Defects usually recognized are: knots, knot-holes, shake, wane, rot, stain, etc. Poor manufacture is also a defect; and grading rules generally require that lumber must be properly manufactured, with parallel edges and square ends.

In the determination of lumber grades, two general classes of usage are considered: First, those in which the lumber is used in its entirety; and second, those in which the lumber is cut to new dimensions in the process of re-working into other products. Into the first class falls the larger proportion of the softwood lumber used for general construction. Dimension, for example, is used for studding, joists, sills, rafters, etc.; and boards are used for siding, sheathing, roof-boards, partitions, and the like. In either case, the lumber is used in essentially the form and size in which it is first manufactured; and the grades provided for it require that the defects shall not be of such character or in such quantity as to impair the usefulness of the piece as a whole. In other words, a piece of dimension may contain knots, shake, pitch streaks, or decay; but these defects must not be so located or so numerous as to render the piece too weak to be used for studding, joists, and similar purposes.

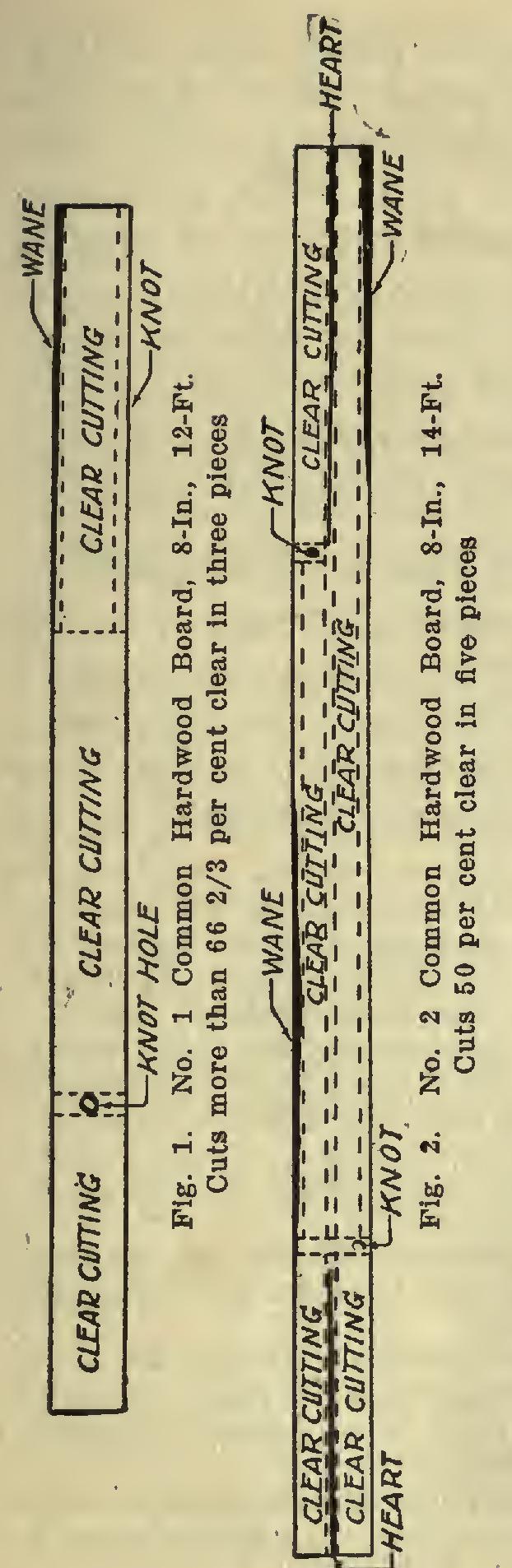

The cutting grades of lumber find their largest use in factories where they are cut to smaller dimensions and re-worked into a multitude of articles, such as furniture, sash, doors, interior finish, packing boxes, etc. Many of the products of these factories contain only sound, clear lumber when finished; but, since the lumber is cut into very differed sizes from those in which it was originally manufactured, it is possible to cut out the portions which contain knots, rot, and other defects, and to obtain clear, sound pieces of the sizes needed for the finished articles. A common requirement in grades of this sort, therefore, is that a certain grade of lumber must contain a specified percentage of clear stock in sections of specified sizes. For example, the grade of No. 1 Shop Common in white pine must contain not less than 50 per cent nor more than 70 per cent of cuttings suitable for use in the manufacture of doors, these cuttings to be of specified lengths and widths. Again, the rules of the National Hardwood Lumber Association require that the grade of No. 1 Common must contain clear stock in pieces 3 and 4 inches wide and 6 and 7 feet long; and that the larger boards of this grade must be of a character which will permit their being cut into a certain number of clear pieces equivalent in total size to two-thirds the area of the original. board.