Sand-Lime Brick

strength and lime

SAND-LIME BRICK Sand-Lime Brick. About the year 1880, some German experimenters discovered the fact that brick made of sand and lime could be hardened in a few hours by heat and the pressure of steam. At that time they had no vessels of sufficient size and strength to withstand the required pressure, and the patents were allowed to expire before the process became a commercial success.

Within the last ten years many plants is nothing in the process of manufacture to make them warp or crack. It is claimed that age improves their strength and hardness, and that they are strong enough for any ordinary work. The makers are constantly improving their product.

Sand-lime brick, as known on the market to-day, are made from a mixture of sand and lime, varying in proportions from 85 to 94 parts of sand to from 15 to 6 parts of lime, according to the respective characters of the limes and sands used. The nature of the lime is probably the most important factor. The successful manufacture of the product depends largely on the perfect mixing of the two materials. The majority of sand-lime brick are made on presses similar to the dry-press machinery used for day brick, but of ex ceptionally heavy construction, the strain on the machinery being so much greater. Rotary presses of German design are also used successfully.

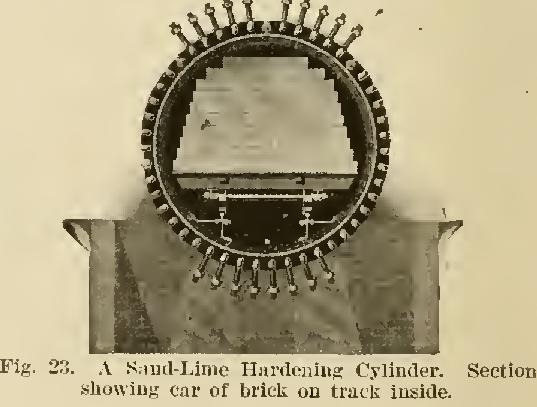

The brick, when molded, are loaded onto cars holding about 1,000, and run into huge cylinders of steel from 45 to 70 ft. long and about 6 ft. in diameter. When the cylinder track is filled with ears, the cylinder-head is bolted, and steam is introduced. The brick are subjected to a pressure approximating 125 lbs. for from 9 to 12 hours. During this time, under the influence of the heat and moisture, most of the lime unites with the sand, and forms a hydrosilicate of lime.

Sand-lime brick are made to conform to the sizes of clay brick, especially dry-press brick. A brick measuring by 4 by in. weighs 5 lbs. When submitted to the absorption test, wellmade brick will show from 4 to 10 per cent. The average crushing strength is from 2,500 to 3,000 lbs. per sq. in. Tests on special kinds of sand-lime brick have shown a crushing strength of over 6,000 lbs. per sq. in.

Sand-lime brick are naturally white or gray in color. Manufacturers arc, however, placing on the market red, buff, chocolate brown, and pink brick. The colors used are similar to those employed in coloring cement products.

There are about 75 sand-lime brick plants in successful operation in the United States. Their number is steadily increasing, and the product is being standardized.

Table I gives data regarding the strength, absorption, etc., of sand-lime brick.

Each of the numbers in the table is the mean of several tests. The sequence of the numbers is of no significance; that is, the numbers in the first line are there by chance.

The modulus of rupture was obtained by breaking the brick, placed on edge between supports six inches apart, the load being in the middle.

The compression pieces were halfbricks, imbedded on both sides in plaster of Paris.

The absorption test was made by heating the bricks to dry them out, and then keeping them in water for 48 hours. Upon being taken from the water, they were wiped dry and then weighed; and the increase in weight was divided by the weight of the dry brick, and the result multiplied by 100.

It would seem, by comparison with the results of tests given in Tables III and IV, that the results for sand-lime brick are about what would apply to rather soft or salmon brick as regards strength, while the rate of absorption is somewhat less for the sand-lime brick. On many accounts such brick are esteemed by many as being superior to clay brick of equal strength, as they are of finer appearance, and they may be used for the facing of interior walls such as hallways, corridors, vestibules, etc.