Gasholders

GASHOLDERS. As the manufacture of gas must be main tained at an approximately even rate throughout the 24 hours, while the rate of consumption varies considerably at the different hours of the day, it is necessary to provide storage for the gas produced during the periods of minimum demand, and also to provide against any temporary breakdown in the manufacturing plant. In the early days of the gas industry the vessel in which the gas was stored was known as a "gasometer," as this vessel had to serve the dual purpose of storing and measuring the amount of gas made. With the advent of the station meter in the year 182o for measuring the volume of gas, the name of "gasholder" was adopted, but even now in Great Britain journalists and others invariably use the technically obsolete word "gasometer." The capacity of the gasholder should be equal to at least 75% of the maximum daily output. There are now f our distinctive types of gasholders: (I) frame guided, (2) spirally guided, (3) dry or tankless, (4) spherical. The frame guided and spirally guided holders may have one or more lifts, the one lift type being known as a single lift holder, and the other as a telescopic gasholder, the latter type being generally adopted for economic reasons. The movable vessel in which the gas is stored is known as the floating gasholder. The steel structure which guides the floating holder as it ascends or descends is termed the guide framing, and is erected round the circumference of the steel or brick tank which contains the water for sealing the sides of the floating gasholder, thus preventing the escape of gas. Gas is admitted into the holder by means of an inlet pipe which passes through the bottom of the tank, and extends to a height of about 6 in. above the water level; another similar pipe is provided as an outlet for the gas to the district mains; both pipes being con trolled by slide valves.

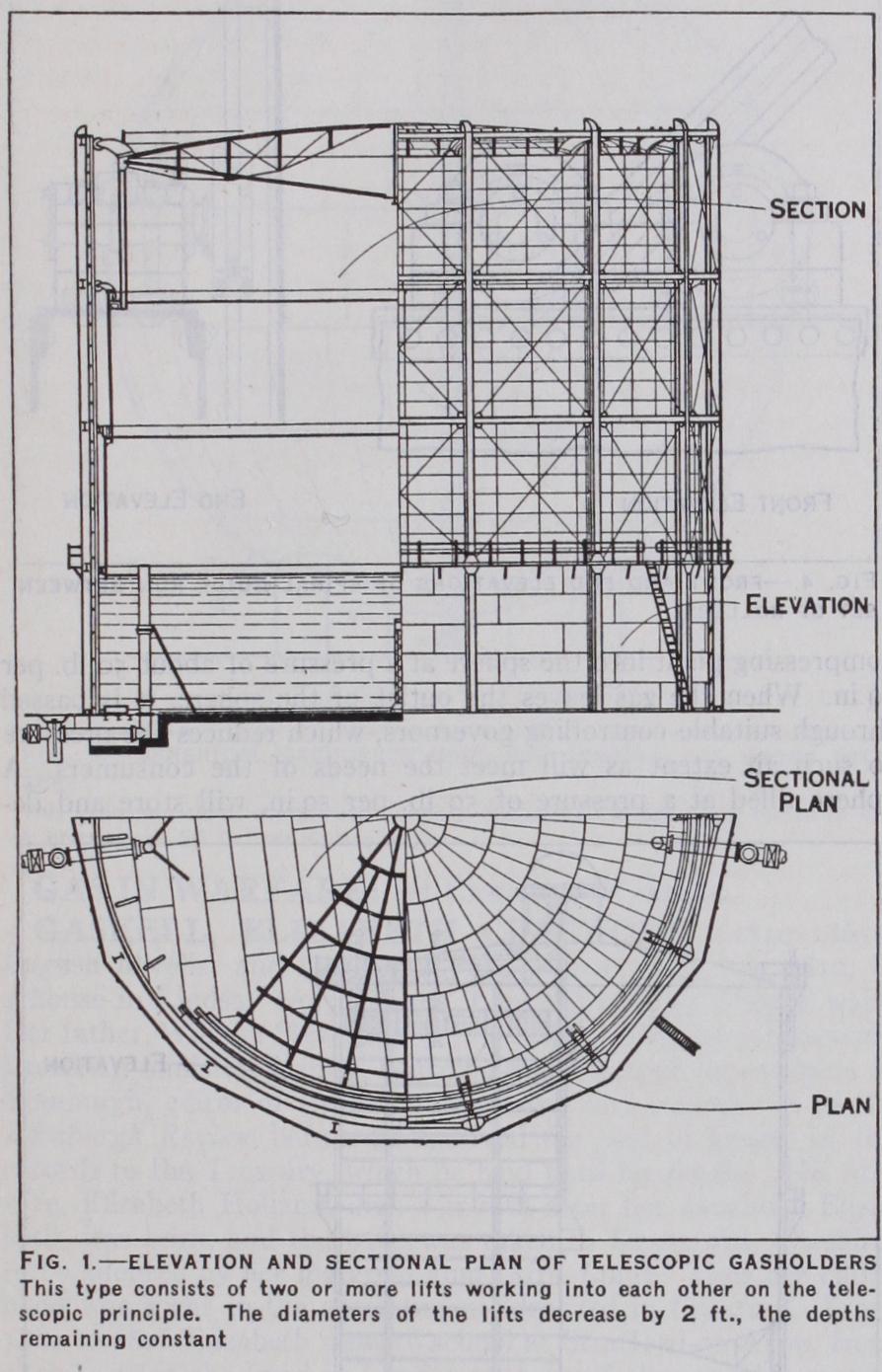

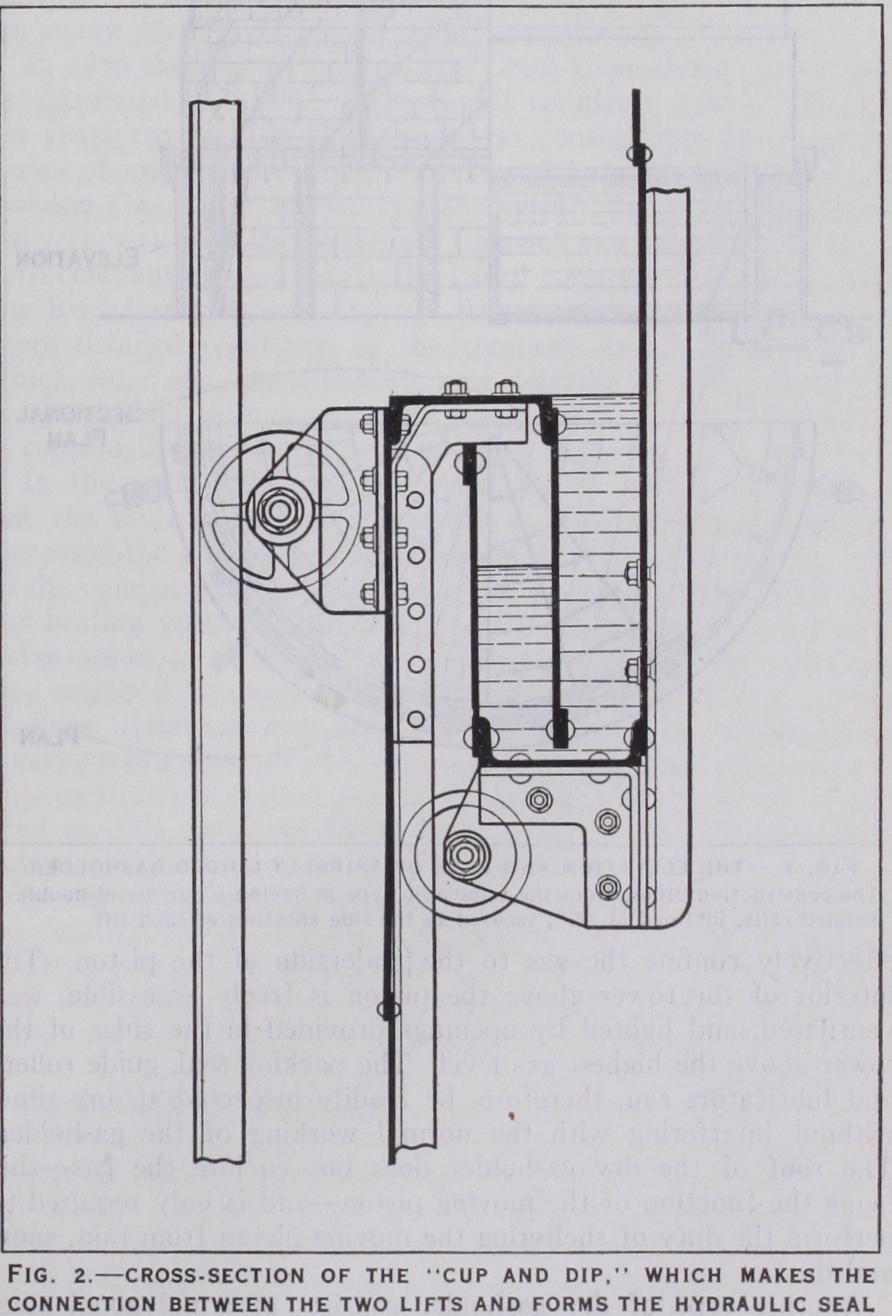

The telescopic form of holder (fig. i) consists of two or more lifts, which work or slide inside one another, much in the same way as an ordinary telescope. The inner or first lift is constructed to a certain diameter, according to the capacity required, and the diameter of each succeeding lift is increased by about 2 ft., whilst the depth of each lift would be constant, and equal to about one fifth the diameter. In order to secure a gas-tight joint between the lifts as they leave the tank, the bottom row of sheeting of the inner lift is prepared with a channel cup about 18 in. deep, whilst the top row of sheeting of the adjoining lift is fitted with an inverted channel cup, usually termed the "dip" (fig. 2) . As the inner lift rises out of the water in the tank, the channel cup engages with the dip, thus making a gas-tight water-sealed joint between the lifts. Each succeeding lift is fitted with a dip at the top, and a cup at the bottom, with the exception of the final or outer lift, which is provided with a dip at the top only, and a strong angle steel curb at the bottom. The crown of the holder is dome-shaped, and when at rest in the tank, is either supported by a trussed steel roof forming part of the inner lift, or upon a permanent steel or timber framing erected in the tank. The sheeting of the sides and crown of the holder is about in. thick, with the exception of the rows of sheets adjoining the cup and dip, and also the junction between the crown and sides of the inner lift, which are much thicker, in order to allow for extra wear and strain at these points. The tank may be constructed in brick, concrete or steel. Brick and concrete tanks are usually constructed by excavating the ground and building up the sides of the tank, so that the top of same finishes about 6 in. above the ordinary ground level. Water-tight ness is obtained by encasing the bottom and side walls of the tank in a layer of clay puddle, or by coating the inside surface of the tank walls with cement. Steel tanks are usually erected on a flat bed of concrete, laid at a foot or so below the normal ground level, the sides being formed of a number of tiers of steel plates varying in thickness to suit the pressure due to the depth of water in the tank. Steel tanks are much less costly than either brick or concrete tanks, and can be much more quickly erected.

Frame Guided Gasholders.

These consist of a series of columns or standards fixed at equal distances round the circum ference of the tank, which are connected together by one or more tiers of horizontal girders or struts, and a series of diagonal brac ing rods, thus forming a continuous tie all round. The guide framing may be carried up to the full height of the holder when fully inflated, or to the top of the second lift only, thus allowing the inner lift to run clear of the guide framing, which is then known as a "flying lift." Channel guide runs are fixed to the inner face of the standards, to form a pathway for the guide rollers— which are attached to the crown and the dip of each lift—to work up and down for the purpose of guiding the gasholder and enabling it to withstand the overturning force of the wind. The underside of each cup is fitted with a corresponding number of radial rollers, which run in channel guides fixed to the inside of the next ad joining lift ; the curb of the outer lift is also fitted with similar rollers working in channel guides fixed to the sides of the tank.

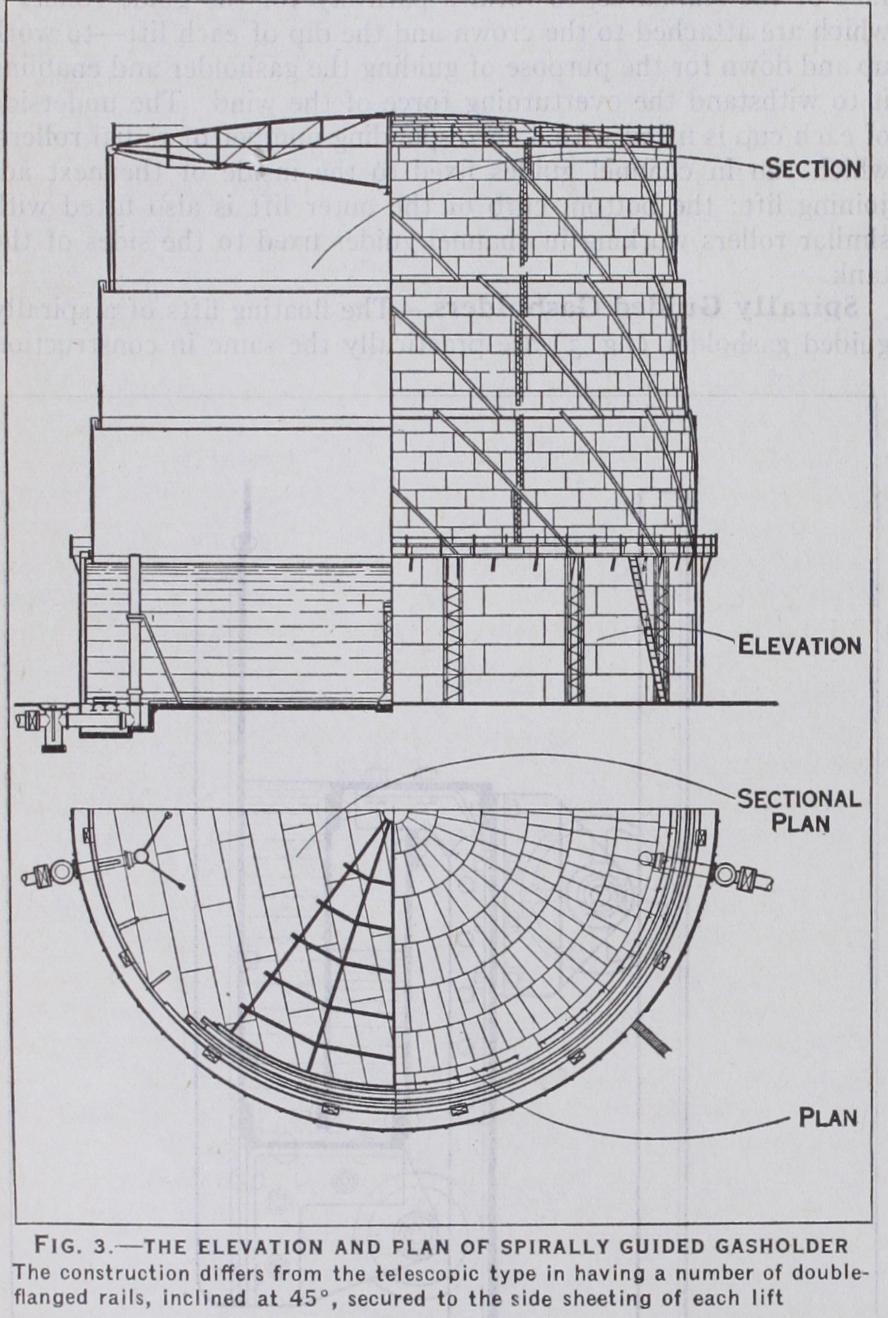

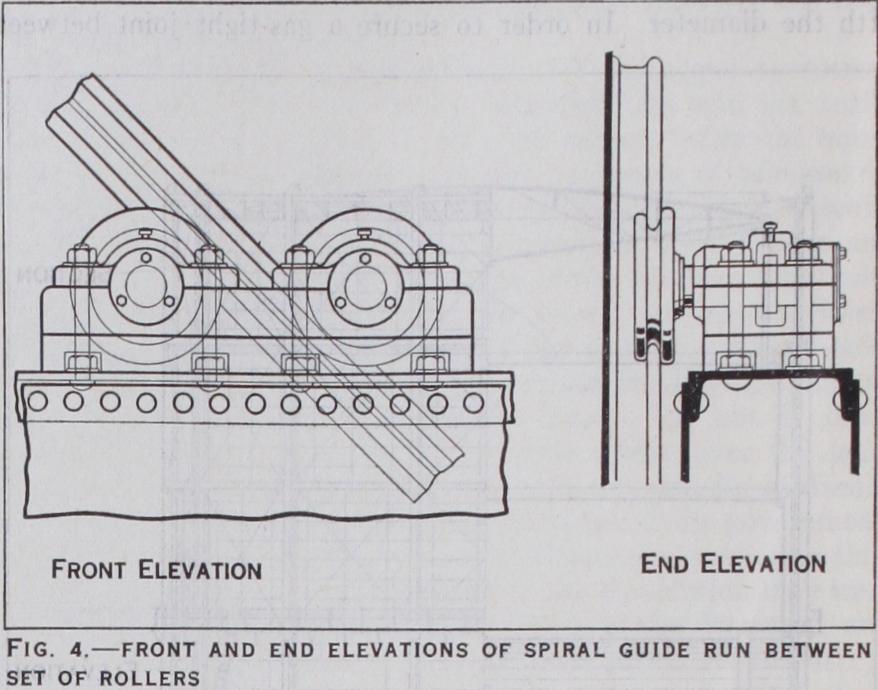

Spirally Guided Gasholders.

The floating lifts of a spirally guided gasholder (fig. 3) are practically the same in construction as the frame guided holder, with the exception that a number of double flanged rails, inclined at an angle of 45° are secured to the side sheeting of each lift at equal distances round the circum ference. The spiral guides run between a corresponding number of sets of rollers (fig. 4) mounted in adjustable carriages, secured to the dips of the holder and top curb of the tank. The action of the holder in rising or falling is comparable with the action of a coarse threaded screw, and the spiral motion thereby imparted to the floating vessel is sufficient to maintain the holder in a level condition, and enables it to resist the overturning force produced by the wind. This form of holder costs from io to 15% less than the frame guided holder.

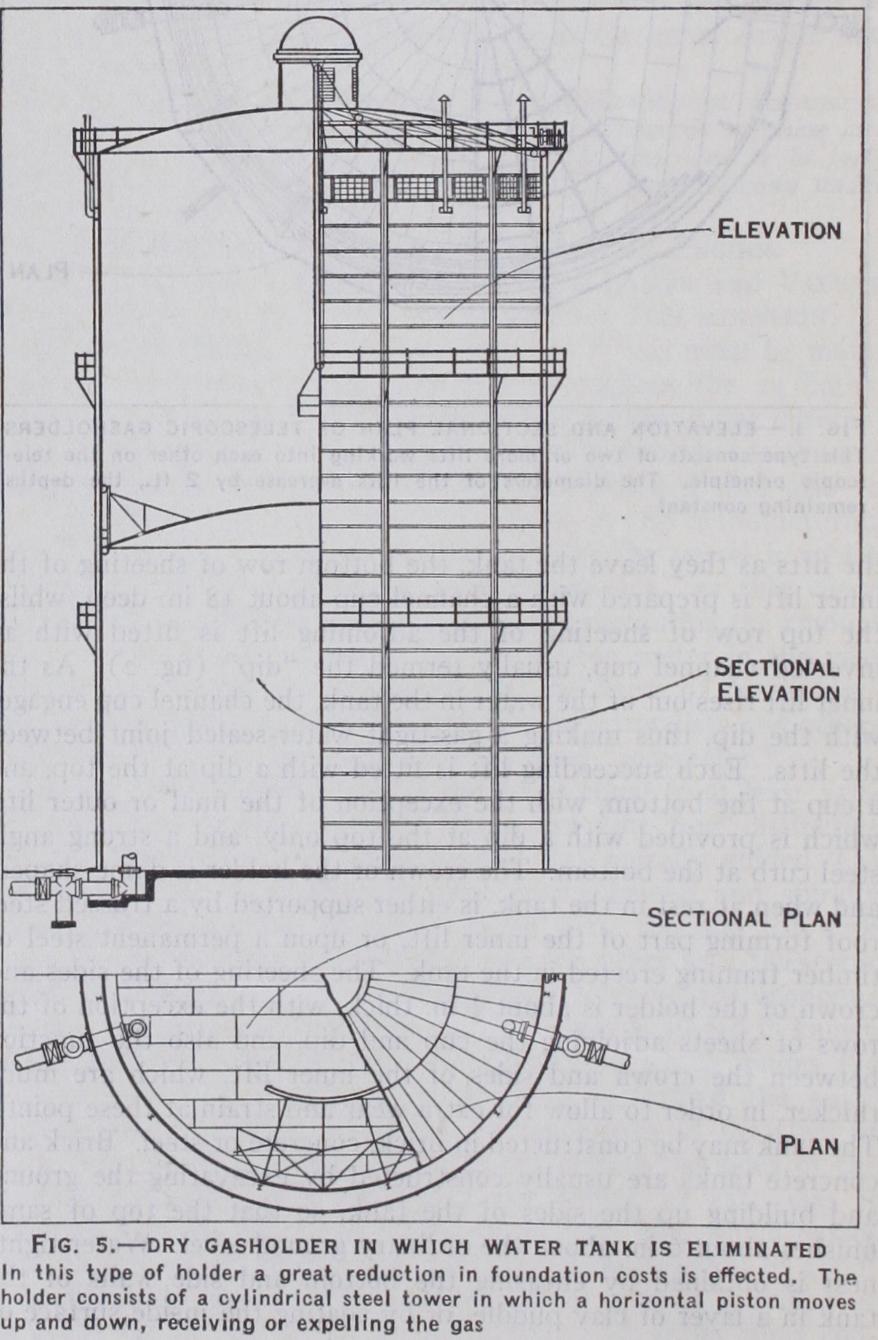

Dry Gasholders.

In this type of holder (fig. 5) the tank with its water content is dispensed with, thereby greatly reducing the cost of foundations. The tankless gasholder consists of a cylindri cal steel plate tower, within which a horizontal disc or piston moves up or down, receiving or expelling the gas. The piston is guided in its vertical movement by a system of rollers, travelling up or down the inner sides of the steel cylinder. The periphery or outer edge of the piston is lubricated and maintained gas-tight by means of several layers of moulded rubber packing rings, which effectively confine the gas to the underside of the piston. The interior of the tower above the piston is freely accessible, well ventilated, and lighted by openings provided in the sides of the tower above the highest gas level. The packing seal, guide rollers and lubricators can, therefore, be readily inspected at any time, without interfering with the normal working of the gasholder. The roof of the dry gasholder does not enclose the gas—this being the function of the moving piston—and is only required to perform the duty of sheltering the moving piston from rain, snow and dust.

Another type of dry gasholder consists of a polygonal steel tower, with movable piston, similar in construction to that previously described, but in this design the periphery of the piston is maintained gas-tight by means of a light gas-tar of moderate viscosity, contained in an annulus formed on the outer edge of the piston. As this seal is not absolutely tar-tight, a small quantity of tar escapes and flows to the bottom of the cylinder, where it is collected in a series of chambers, and is pumped up again by a number of automatically controlled electric pumps, to the top of the tower.

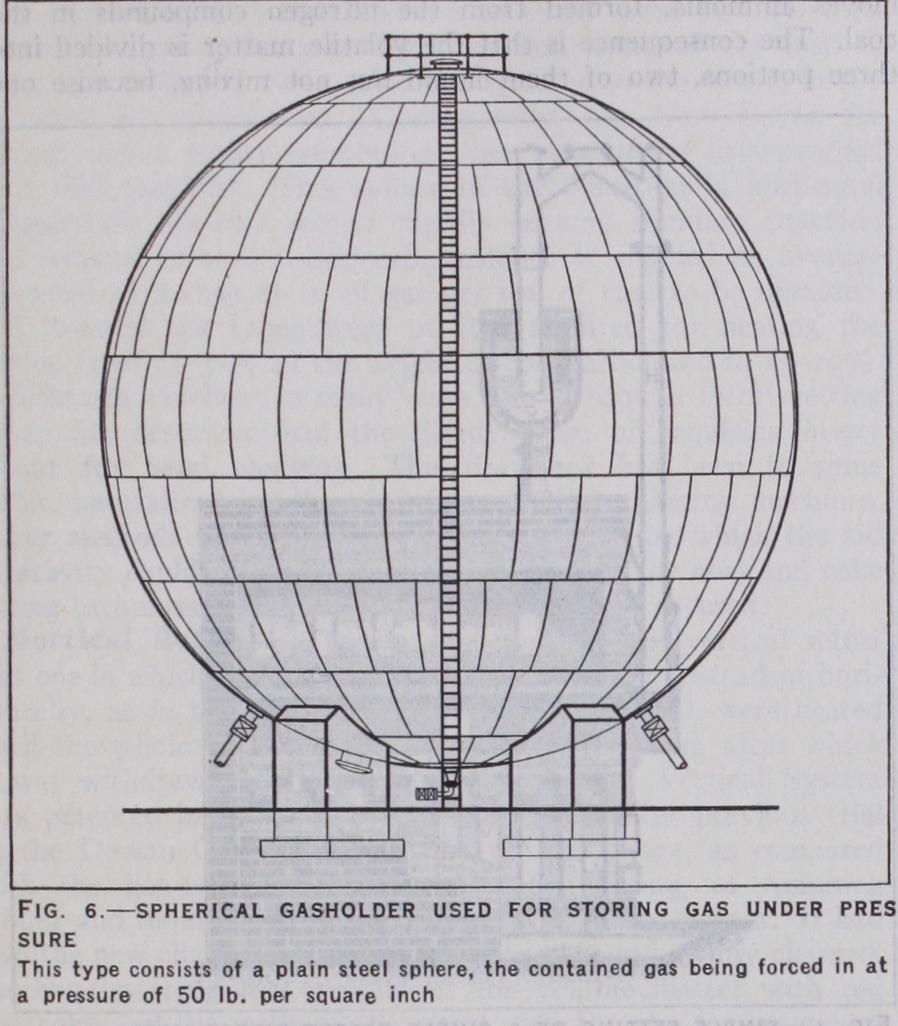

Spherical Gasholders.

This type (fig. 6) is principally used for storing gas under pressure. It is a plain sphere of simple con struction, usually about so ft. in diameter, formed of steel plates about of an inch thick. The gas to be stored is forced by a compressing plant into the sphere at a pressure of about 5o lb. per sq.in. When the gas leaves the outlet of the sphere, it is passed through suitable controlling governors, which reduces the pressure to such an extent as will meet the needs of the consumers. A sphere filled at a pressure of 5o lb. per sq.in. will store and de liver about 33 times its cubical content at the lower pressure re quired in the distributing mains.

See R. J. Milbourne, Gasholder Design and Construction.

(R. J. Mi.)