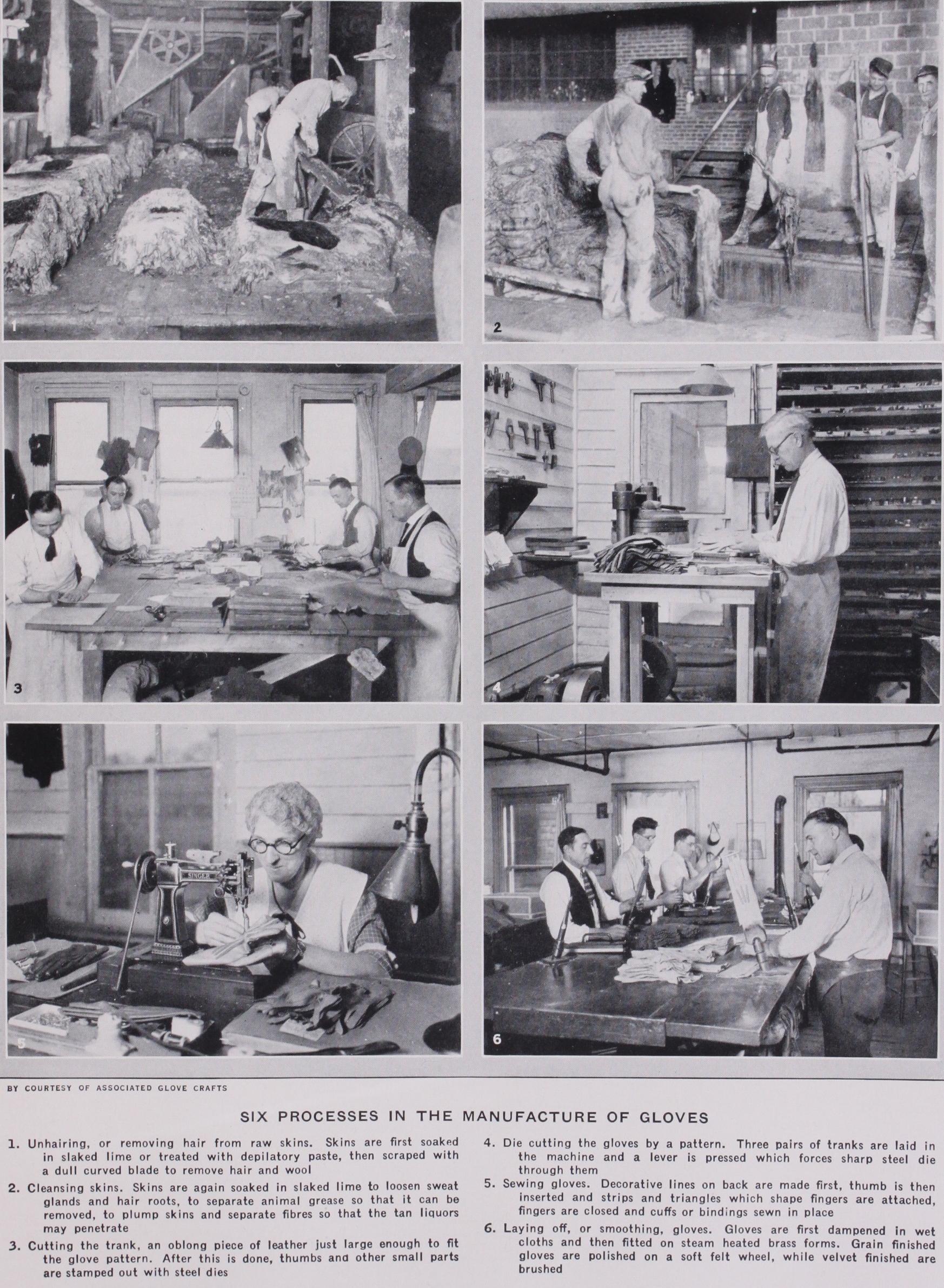

Glove Manufacture

GLOVE MANUFACTURE. Modern gloves fall naturally into two main groups: (I) leather gloves; (2) fabric and knitted gloves. The character of a leather glove depends partly upon the type of skin used, but more particularly upon the processes by which the leather is produced.

Glove Skins.

A large variety of skins are used by the trade; but the humble sheep supplies the bulk of the raw material. Apart from sheepskin, the principal skins used for grain (or glace) glove leathers (i.e., those finished on the hair side of the skin) are kid, goat (chevrette) and lamb. French "national" skins from milk-fed kids are used extensively for ladies' high grade gloves ; Tuscany, French "regord" and Kasan (Russia) lambskins are of high repute. In the grain group, also, the genuine Cape or South African hairy sheep furnish a strong, pliant leather for men's gloves. Many so-called "Capes," however, are made from Spanish, oriental or domestic sheepskins. Pig-skin and colt skin are used for gloves to some extent in America, and dog-skins are occasionally made into glove leather.

For velvet finished gloves, reindeer and buckskins yield the finest leathers, but they are expensive. The diminutive North African gazelle (a tiny creature, so small that three skins barely suffice for a single pair of gloves), the Arabian (or Mocha) sheep, and Sudanese sheep also furnish capital leather for velvet finishes. Suede leathers (i.e., those finished on the flesh side of the skin) are produced from kid, lamb and sheep-skins. Sheep-skins, again, furnish most of the raw material for so-called "chamois," or washleather gloves, and also for what in the trade are called "doeskins." Many glove manufacturers dress and dye skins for their own use; others purchase glove leather ready dressed. The skins are first partly cleansed in tanks or pits filled with water. They are then de-haired, the flesh side of the skins being painted with a solution of slaked lime and sodium sulphide or lime and red arsenic, which loosens the hair or wool and facilitates its removal by hand or machine. Any flesh adhering to the skin is next re moved by "beaming" or "fleshing." Beaming is a hand operation, the skin being laid across a sloping beam let into the floor and the operative shaving away the flesh with a beaming knife. In the fleshing machine, which performs the same operation, the knives are mounted spirally upon a revolving cylinder, under which the skins are passed as through a mangle. The cleansed skins are steeped for some weeks in pits or vats containing a solution of slaked lime to loosen the sweatglands and hair cells and to re move grease, dirt, etc. Liming also makes the skins plumper. More washing follows, and the hides are then placed in a "puer" (or "bate") consisting either of a solution of dog manure, or a chemical solution of pancreatic extracts in combination with ammonium salts. "Drenching" is the next stage, wherein the raw material of the glove is immersed in vats containing a fer menting infusion of flour, pea-meal or bran, in which the skins swell or "rise" still more. Alternatively skins are pickled in a weak solution of sulphuric acid and salt. "Puering" and "drench ing" or "pickling" complete the reduction of the hides to a soft, porous, pulpy, gelatinous condition which facilitates the entry of the dressing ingredients into the fibres of the skins. Further rinsings and cleansings follow, and the skins are then gently scraped with a scudding knife to remove the last vestige of hair or scum.

Dressing.

Dressing proper follows. There are several proc esses which may be adopted, according to the type of leather re quired and the practice of the factory. Different factories use different methods to produce the same kind of leather.The "tawing" method, or white dressing, is very commonly used. A typical tawing mixture consists of 4 parts alum, 2 parts salt, I part egg-yolk and 5 parts flour. Sometimes a little vege table oil is added. The mixture is dissolved in water (about i 2 lb. to 2 gal.) and is applied by means of a drum-tumbler—a vessel shaped like a drum, the inner sides of which are fitted with pegs. The drum rotates on its own axis, and the pegs knead the mixture into the skins. Subsequently the skins are "stoved," or dried in heated chambers and emerge in the "crust" stage, re sembling a piece of damp washleather which has dried hard in the sun. They are softened by "staking," a process in which the hides are drawn (flesh side downwards) over a blunt metal tool, fixed to a short stake or post set in the floor. Machine staking is now much used, especially for strong skins. The skins are later pared to an even thickness and usually stored for long periods before dyeing. Colour is applied either by brushing the dye on the outer surface of the leather, or by immersion in a drum tumbler. Vegetable or bark dyes are much used; but aniline and coal tar colours are suitable.

The foregoing process is much used for dressing glace leathers, such as kid, lamb, nappa (a German term used to distinguish a drum-dyed article from a brush-dyed) , and many so-called "Capes." Glace or grain leathers are finished by polishing the grain side with a lamb's wool pad, a glass slicker or a revolving felt wheel. Suede (named after Sweden, the country of its origin) is tanned by an alum and salt process, but it is finished by buffing the flesh surface on an emery wheel. Real "mochas" are dressed with lactic acid, alum and egg yolk; but the grain is first frized (raised with a frizing knife) and the grain side finished by buffing with emery and pumice.

Bark tanning (in which oak, chestnut, gambier, sumach and other barks are used) is adopted for leathers like genuine "Cape," goat, colt, pig and similar heavy-weight skins.

An oil tannage is used to produce so-called "chamois" leather and washleather. For these, "fleshers" (the flesh section of the split sheep-skins) are dressed with cod-oil in a "stocking" machine, which pummels the oil into the leather. The process is sometimes termed "samming," and it involves repeated applications of oil, each dressing being followed by stove drying. Reindeer and buckskins are often oil-dressed, as are some "degrains"—leather with the grain "frized" or shaved off. These are then dyed as re quired. White washable leather is tanned by drumming skins in a solution of sodium carbonate and formaldehyde, later treating them with an emolient of egg-yolk and neat-foot or olive-oil. Much progress has been made sir`ce 1920 with chrome dressing, and an entirely new range of coloured washable gloves is available in consequence. This process is much used for washable grain leathers, particularly in America; but velvet finished, especially "degrains" made from frized gazelle or Cape, Spanish and Suda nese sheep are successfully treated in this way. The tannage is effected by drumming in a solution of chrome salts, after which the skins are treated with an oil emulsion. "Doe-skins" are usually oil-dressed sheep-skins or laml"-skins dyed with a liquid clay dye. In America, they are dressed by the formaldehyde process. Gazelle, antelope and the various deer-skins are of ten "degrained" (or frized) and dressed with a velvet finish. Sometimes the white tannage is used and sometimes the formaldehyde or chrome process.

Glove-cutting.

Glove-cutting is a twofold operation. The cutters first stretch and manipulate the skins, and then cut them into oblong "tranks" of leather. Several tranks are placed to gether in a punching press fitted with a "calibre" (knives shaped like a double thumbless hand) and the shaped glove is punched out at one operation. "Fourchettes" (pieces for the sides of the fingers) and thumb pieces are punched out separately.The work of sewing is principally a cottage industry. Hand sewing is preferred for the highest class of work; but machine sewing is general. Three special types of stitch are used :—(i ) "round seam" (for light-weight gloves), in which the edges of the leather are brought together, back to back, and each stitch goes through the leather, and over the edge; (2) "prix-seam" (for heavy-weight gloves), in which the edges are brought to gether and the stitching goes through and through, parallel to the edge ; and (3) "pique," in which one edge is lapped over the other, and the stitches sewn through. When sewn, the gloves are dressed on heated metal "hands" and ironed and polished ready for boxing. Fur gloves are made in much the same way, except that the fur is cut by hand.

The annual production of leather gloves fluctuates consider ably; fashion and the severity of winter weather have an impor tant bearing on demand. The principal centres of manufacture are France, the United States, Italy, Germany, Czechoslovakia, Eng land, Belgium, Luxemburg and Canada.

The French industry dates from the i i th century. It is carried on at Grenoble, Millau, St. Junien and Niort, and there are large dressing yards at Annonay in the Ardeche. Though France is the largest glove manufacturing country in the world, no figures of the annual production are available. The output is chiefly in kids, lambs and light-weight suedes and washables, and more than 75% of the output is exported.

The glove industry of the United States dates from 1760, when Sir William Johnson introduced a colony of Scottish glovers from Perth. These founded the town of Gloversville, Fulton county (N.Y.), the chief seat of the industry. Production (chiefly of heavier types) has increased very rapidly since the World War, and has reached 3,500,000 dozen pairs annually. The majority are sold in the home market.

Czechoslovakia (Bohemia) manufactures mainly kid, nappa and chamois gloves. Annual output exceeds 1,250,00o dozen pairs, and the bulk are exported. Prague is the chief centre, and Kaadan (or Caadan) is famous for cheap washables.

The German industry is centred in Bavaria, Munich being the principal centre; and there are factories in Berlin. A large part of the output (kid, suede, nappa and lined gloves) is exported, shipments totalling over 500,00o dozen annually. The output of leather gloves is about I,soo,000 dozen pairs.

The chief Italian glove town is Naples (where cheap kid and lamb gloves are made) ; Milan, Turin and Genoa are smaller centres producing better quality gloves. Over 5o% of production is exported, and annual shipments increased from 200,000 dozen pairs in 1921 to 75o,000 dozen in 1925, but fell to soo,000 dozen in 1926.

The British leather glove industry is centred mainly at Wor cester and Yeovil ; but it is carried on in many scattered hamlets in the west country and in Oxfordshire. Annual output fluctuates between 750,00o and i,000,000 dozen pairs; large quantities of lined and heavy-weight gloves being made.

Fabric Gloves.

Fabric gloves are of two kinds : (I) gloves cut from knitted cotton or silk fabric; and (2) knitted woollen gloves or "Ringwoods." The fabric for the former is knitted on warp-knitting machines of the Atlas or Milanese type, bleached or dyed and sometimes finished to simulate suede or washable or any other velvet-finished leather by treatment on an emery or other buffing wheel, or by teazles. The fabric glove is cut out and sewn much in the same way as a leather glove. Germany manu factures the bulk of the world's supplies, about 7,000,00o dozen pairs. The industry is centred around Chemnitz (Saxony). The annual production is largely exported, the value of the annual shipments fluctuating between 4o,oOo,00o and 7o,O00,00o marks. Fabric gloves are also made in France at Paris and Lyons and in the English glove centres. Superfine silk gloves are made in New Jersey, U.S.A.Woollen gloves are made in hosiery mills. The seamless type is produced, partly on circular knitting machines (wrist and hand) and partly on flat hand-operated machines (thumbs and fingers). Wrought gloves are usually knitted on straight bar machines, which enable various designs to be worked. The gloves are seamed on a cup-seaming machine. Leicester, Nottingham and the Scottish border towns are the main centres of manufacture.