Woollen Manufacture

swift, wool, rollers, stripped and card

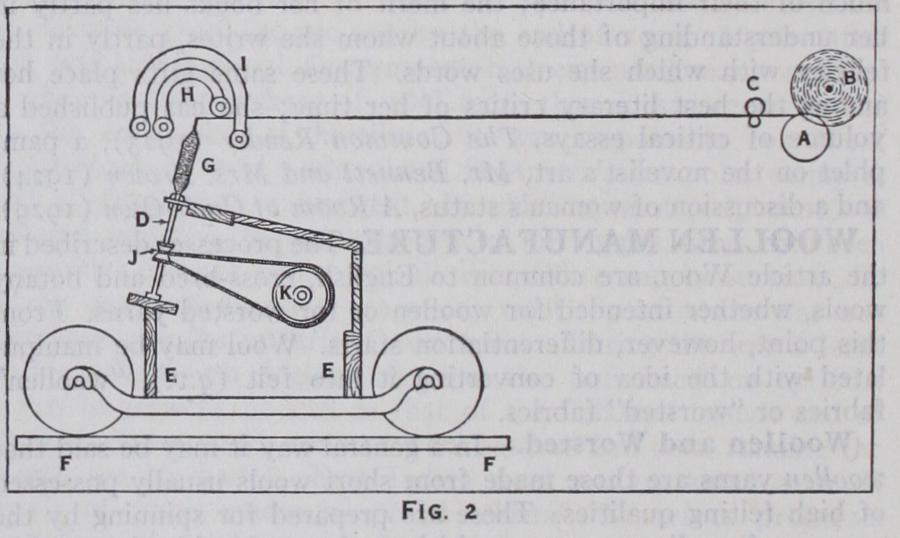

Carding.—Carding was originally effected by hand, two flat boards with convenient handles, covered with teeth or card cloth ing, serving as a means of teasing out lock by lock, fibre by fibre, reversing root to tip and tip to root, so that a perfect mixing of the fibres resulted. It was but natural that, when an attempt was made to render the carding operation more mechanical, the opera tion should be converted into a continuous one through the adop tion of rollers in place of flats. Flats combined with rollers still maintain their position in cotton carding, but in wool carding the pure roller card is employed. The factors of carding are size of rollers, speeds of rollers, inclination and shape of teeth and density of card clothing. Probably no operation in the textile industries is so little understood as carding. Thus the long wool carder would think a man an idiot who suggested the running of the teeth of the various cylinders actually into one another, while the short mungo carder regularly carries out this idea, and so on. The underlying principle of carding, however, is shown in fig. 1, in which a sec tional drawing of part of a card is given. The wool is carried into the machine on a travelling lattice and delivered to the feed rollers A, A', A" of which A and A" in turn are stripped by the licker-in B working at a greater speed point to smooth side. This in turn is stripped by the angle stripper C again working at a greater speed point to smooth side, which in its turn is stripped by the breast D —the "carrying-forward" and swiftest carding cylinder in the ma chine. The swift carries the wool forward past the stripper E— which as a matter of fact is stripped by the swift still working point to smooth side—into the slowly retreating teeth of the first worker F, which, being set a fair distance from the swift, just allows well laid-down wool to pass, but catches any projecting and uncarded staples. The worker in its turn is stripped by the strip per E, which in turn is stripped by the swift as already described. The passage of the wool forward through the machine depends up on its being carried past each worker in turn. Thus from beginning to end of a machine the workers are set closer and closer to the swift, so that the last worker only allows completely carded wool to pass it. Immediately on passing the last worker F' the wool is brushed up on the surface of the swift by the "fancy" G—as a rule the only cylinder whose teeth actually work into the teeth of the swift and the only cylinder with a greater surface speed than the swift. The swift then throws its brushed-up coating of wool into the slowly retreating teeth of the doffer H, which carries it forward until angle stripper C' strips the doffer, to be in its turn stripped by swift D' and so on. The speeds of the cylinders are in the first place obviously dependent upon the principle of carding adopted, the greater speed always stripping (save in the case of the fancy). As to whether the speed shall be obtained by actual revolutions or by a larger diameter of cylinder depends upon the nature of the wool to be carded (long or short), the part which each cylinder has to play in the card, and upon the question of wear of clothing and power consumed. •As a rule the strippers are all driven from a smaller circumference of the swift to obtain conveniently the necessary reduction in speed, and the slowly revolving workers are chain driven from the doffer, which indirectly receives its motion from the swift. The principles involved in the relative inclinations of teeth are very apparent, but the principles involved in the relative densities of teeth on the respective cylinders are again much involved and little understood.

A complete scribbler or first card engine consists of a breast, or small swift, and two swifts with the accompanying workers, strip pers, fancies, doffers, etc. The wool is stripped from this card as a thin film by means of the doffing comb. This film is sometimes weighed on to the next machine—whether intermediate or con denser—a given weight giving a definite count of condensed sliver.

Should an intermediate carder be employed, there must be an automatic feed, taking the wool, as stripped from the last doffer of the intermediate, and cross-feeding it evenly on to the feed sheet of the condenser. It is now more usual to automatically weigh into the scribbler and automatically feed the condenser or, if an inter mediate is employed, both the intermediate and condenser. The condenser is a one-swifted or two-swifted card, the only difference in principle being that, whereas the sliver comes out of the scribbler or intermediate in one broad film, it is broken up into a number of small continuous slivers or films as it issues from the condenser, each one of which will ultimately be drafted or drawn out and twisted into a more or less perfect thread. These slivers— which are delicate and pith-like in substance—are wound on to light bobbins, and these bobbins are placed on the mule for the roving, or final spinning operations. There are many forms of condensing mechanisms such as the single-doffer, the double doffer and the tape-condensers, which cannot be described here.

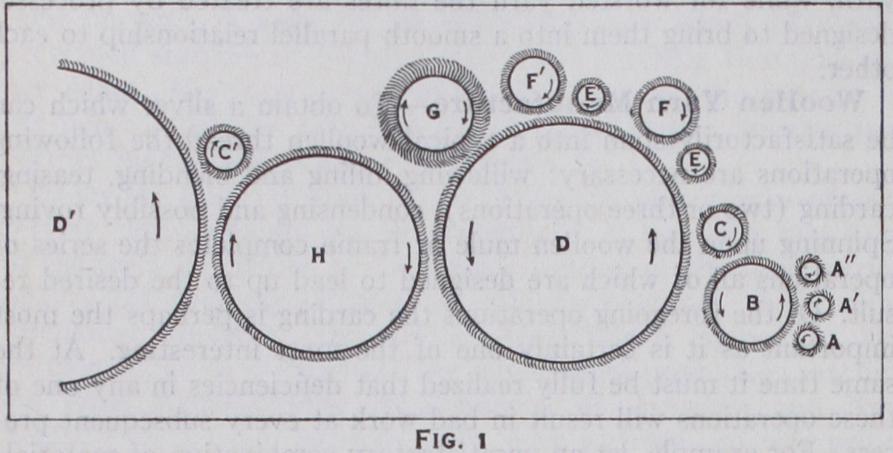

Mule Spinning.—The principles involved in mule spinning are comparatively simple, but the necessary machinery is very com plex; indeed it is questionable if a more ingenious machine than the mule exists. The pith-like slivers received from the card must be attenuated until the correct count of yarn is obtained; they must be twisted while this attenuation or drafting is in process, otherwise they would at once break; and after being attenuated to the required fineness the requisite number of turns must be in serted. Great stress must be laid on the effects of what is termed the "drafting-twist" noted above; it is probably this simultaneous drafting and twisting which develops the most pronounced char acteristics of the woollen yarn and cloth, and differentiates it en tirely from the worsted yarn and cloth. The mule (see fig. 2) con sists fundamentally of the delivery cylinders A, upon which the sliver bobbins B from the condenser are placed, which deliver the slivers as required to the front delivery rollers C (these rollers controlling perfectly the delivery of sliver for each stretch of the carriage), and the carriage EE carrying the spindles which may be run close up to the front delivery rollers and about two yards away from them to effect the "spin," which is of an intermittent character. The spindles D are turned by bands passing round a tin drum K in the carriage, but this motion, and every other mo tion in the mule, is controlled perfectly from the headstock. In brief, the operation of spinning is as follows : as the carriage be gins to recede from the delivery rollers these rollers deliver con densed sliver at about the same rate as the carriage with its spindles moves out, the spindles putting in a little twist. When the carriage has perhaps completed half its traverse (say 36") away from the front rollers these suddenly stop delivering the condensed sliver, the carriage travelling more and more slowly outwards until it completes its traverse, drafting the sliver out to perhaps double the length. This drafting could not be effected but for the "draft ing-twist," which, running into the thin parts of the yarn during drafting, strengthens them and thus from beginning to end equal izes the thread. Upon the completion of drafting the spindles are thrown on to "double speed" to complete the twisting of the 72" of yarn just spun as rapidly as possible, the carriage being allowed i to run inwards for a few inches, to allow for the take-up due to twisting. The mule now stops dead, backs-off the turns of yarn from the top of the spindle to the bottom, the faller H wire falls into position to guide the thread on to the spindle to form the re quired cop G, and the counter-faller I wire rises to maintain a nice tension on the yarn. The carriage now runs in, the spindles being revolved to wind up the yarn, and, in conjunction with the guiding on of the faller wire, builds up a firm cop or spool.