Bunkering of Ships

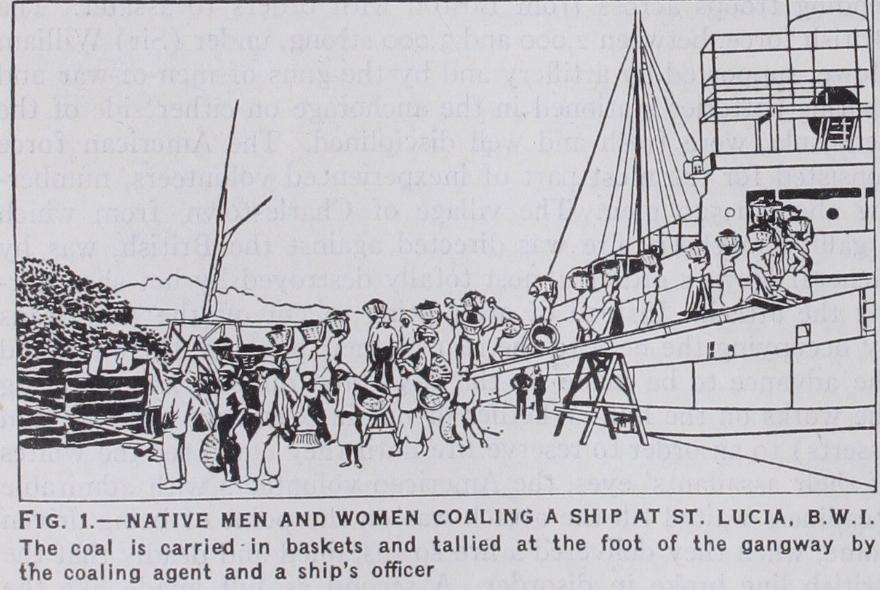

BUNKERING OF SHIPS. Coal bunkering has naturally been in use ever since steamships came into existence. In the early days it was performed by hand, which was an extremely slow process. It is no uncommon sight to see, even to-day, gangs of from so to i 5o men and women, carrying baskets of coal and handing them up the ship's side, see fig. i ; the output is 3 to 4 tons per carrier per day. Apart from the economic aspect, hand bunkering was not so bad when the loading and unloading of vessels was slow, but with modern devices for handling cargo, coal bunkering becomes a more important proposition.

Before discussing the different methods and devices in use, it must be mentioned that there are fundamental differences, depending upon the particular port concerned, its traffic, and the nature of the fuel employed.

At the Welsh ports, at Liverpool and at ports on the Tyne and Humber, the coal loaded is almost exclusively cargo ; it is all rail borne, and is transferred from the sidings by huge steel struc tures on the quayside, known as coal hoists. By raising the trucks individually and tipping them, the coal is loaded by means of a telescopic chute. These coal hoists are also occasionally used at these ports for bunkering vessels. On the other hand, at ports E. H. Lecky, History of England in the Eighteenth Century, iii. 428.

'General Gage's despatch. American Remembrancer 1776, part II., D. I12.

where general cargo is principally handled, water-borne coal is almost exclusively used for bunkering purposes, because the quay space is too valuable for the provision of coal hoists. The coal is unloaded into barges. and then transferred by manual labour or mechanical devices into the bunkers of the steamers.

At the Victoria and Albert docks—which may be taken as a typical example—about 3o% of the coal is still loaded by manual labour, while about 7o% is mechanically bunkered. The former process is performed by winch barges by the "whip and skip" method. An average of i oo tons per day of 8 hours can thus be transferred by a gang of g men.

Mechanical Bunkering Plants

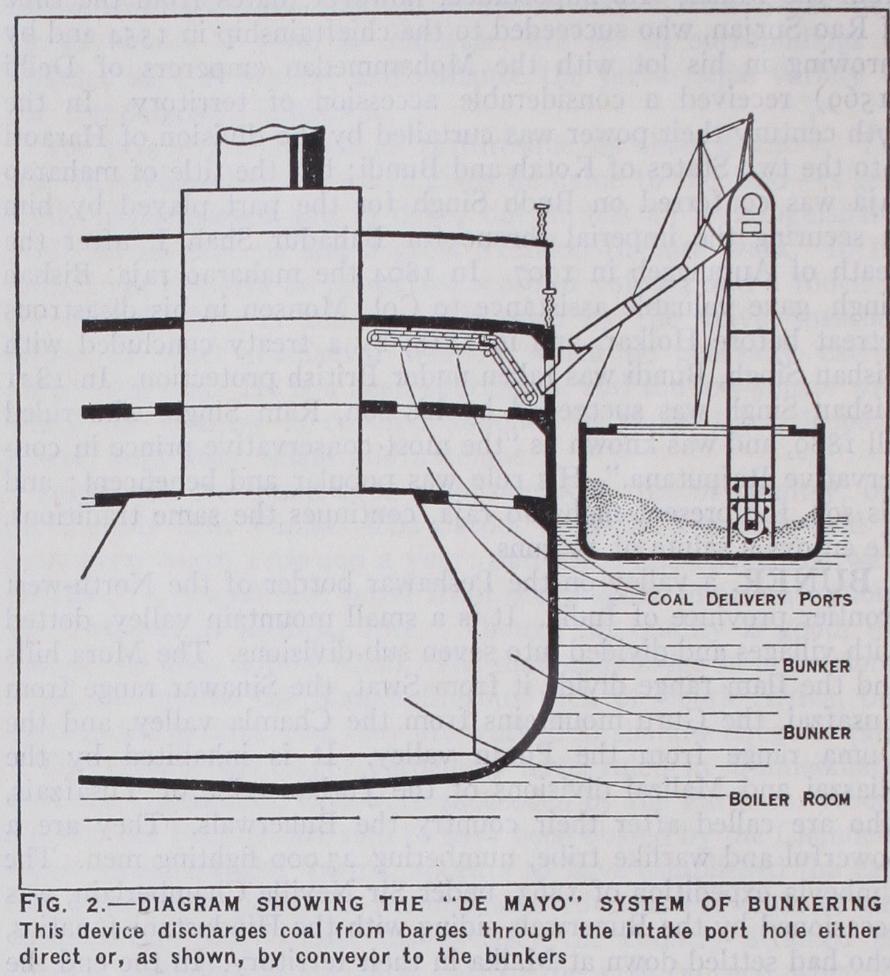

may be divided under two heads : A.—Portable loading devices, self-contained, but with no sup porting structure. They are attached temporarily to the ship to be coaled ; and B.—Floating loading devices mounted on pontoons.A. The "De Mayo" bunkering device, which is more partic ularly used in America, is a completely enclosed bucket elevator, suspended singly, or in series, from ships' tackle or from the boom of a coaling barge; it discharges coal from barges alongside, both in and off shore, and at the intake port-hole. With this system, portable conveyors are sometimes employed for trimming the coal in the bunkers, or for loading through deck hatches in con nection with an adjustable portable elevator. Such a combination is shown in fig. 2. This device is used in the Panama Canal for bunkering vessels which do not touch at the piers.

The "Michener?' coaling elevator (see fig. 3) consists of a spe cial type of bucket elevator, suspended from the side of the vessel, with the feeding end in the coal barge and the delivery end reaching right into the bunker port of the vessel. By an ingenious device the elevator can be dipped farther into the barge as the coal is unloaded, without altering the position of the de livery end. The receiving terminal revolves in the opposite direc tion to that usual in elevators; it is, therefore, termed under-fed. After a vertical run, beginning at the lower terminal, the chain forms a bight, negotiates the guide idler G, and assumes an essen tially horizontal position towards the power-driven sprocket E. During this short run the coal leaves the buckets, dropping into a slightly hoppered, bifurcated receptacle, from which it is led, by means of telescopic chutes, into the bunkers. The average capacity of one unit is 125 tons per hour, with an expenditure of r o h.p.

B. The "Temperley" transporter is used either slung from the ship's tackle or from special coaling barges. It is self-contained and consists essentially of an I-shaped boom having a traveller running on the lower flange. The boom is triced up to the mov able framework or shear legs and the traveller is worked by two ropes engaging with the two drums of a double-barreled winch. The boom is so arranged as to reach athwart the coaling barge and the vessel to be bunkered, in which coal can be dumped at any number of predetermined points.

The "Suisted" bunkering ele vator (see fig. 4) consists essen tially of a bucket elevator and band conveyor, mounted on two pontoons with room between for the coal barges; one of the pon toons contains the generating plant for power and light, while in the other is provided accommo dation for the crew. It is so built that the upper structure straddles the barges to be unloaded, de vouring their contents, and dis gorging them into the bunkers of a vessel. The important feature is the way in which the bucket elevator is mounted between the two pontoons, so that it can be raised and lowered, as well as racked mechanically from side to side, in order to pick up the coal with the minimum amount of trimming. The 58f t. elevator is driven by a 6oh.p. electric motor. Each bucket holds 4 cwt. of coal. The 48f t. band conveyor is 3ft. wide and runs at 400ft. per min ute. The plant has a capacity of 30o tons per hour and requires nine men to work it. Since the racking of the elevator is limited by the hatch coamings, some trimming of the coal is neces sary and this is performed by f our of the nine men.

In some instances devices of this type have been built with a single large trimming pontoon to carry the coal and thus dispense with the barges, but since the economy of such expensive bunk ering devices depends largely up on their being fully employed, it is short-sighted policy to use them for carriers also, unless they are of very large capacity. The best known of such devices are built in Holland by the firms of Schmulder, and Werft Conrad (see fig. 5) ; others are built by William Doxford & Sons, Ltd., Sunderland.

At Rotterdam, where the harbour is exceptionally spacious, the mechanical devices used are floating hoists on high steel struc tures which are fitted with grabs, but a great deal of dust is created during operation.

Harrisons (London) Ltd.'s bunkering pontoon (see fig. 6), is a device, unlike the "Suisted," mounted on one large pon toon, which, for the sake of stability, also carries the generating plant, including the motors and winches for the various move ments. It consists of a 2-ton grab and bogie, which travel on a horizontal boom; a 3o-ton bunker on board the pontoon, into which the grab discharges; a measuring device which doles out the coal from the bunker alternatively into the twin vertical skip hoists with bottom door discharge ; these raise the loads to a smaller receiving chamber which can be elevated sufficiently high for bunkering the biggest ships. Each of the two skip hoist units has a capacity of one ton, and they discharge alternatively into the receiving chamber, whence the coal is led, by means of a gravity chute, to any of the bunkering hatches, side or amid ship. The measuring chamber and the skip hoists when in their lowest position are so enclosed as to exclude dust production; the coal-receiving chamber, high up in the structure, is also similarly enclosed.

When the bunkering device has been placed close up against the vessel to be coaled and a coal barge brought into position on the other side, the boom, on which the grab runs, is brought from its upright housed position to its horizontal working posi tion; the grab is run out over the barge, lowered into the coal, and a charge lifted and deposited into the receiving bunker. The gravity chute is telescoped at the delivery end and can be slewed in either direction from the receiving chamber to the bunkers of a vessel. The upper terminal of the hoist is practically a com pensating dumping frame which may be adjusted to any desired position by a separate motor and winding gear without stopping the working of the plant. In that position each skip is arrested for a few seconds, the bottom door automatically opened and the coal delivered into the receiving chamber. The door is then automatically closed as the skip returns to be refilled. The plant is worked by four men only. Perhaps the greatest advantage of this type of plant is the exclusion of dust during the bunkering process.