Compressed Air

COMPRESSED AIR. It would be possible to enumerate some 200 distinct applications of compressed air in the operation of machines and in manufacturing processes. No other power agent has such a varied range of uses, or is so conveniently stored and conveyed. Its applications may be broadly divided into free and enclosed action. In the former category are, for instance, the air-jets for cleaning machinery and fabrics, the nozzles for feeding air to gas and oil burners, the air-lifts for pumping, and operations such as the blowing out of tanks in sub marines and oil ships, glass blowing, sand-blasting, and the spraying of whitewash, distemper, paint, varnish and enamel. These spraying processes are far more economic than the brush methods. In one case a ship required the services of six men for 136 hours to paint by hand, while with compressed-air spraying a similar ship was painted by two men in 4o hours.

The category of enclosed action comprises scores of methods wherein the air acts in a cylinder to give a power movement, or is otherwise confined, e.g., in portable pneumatic hammers for chipping, riveting, caulking, rock drilling, concrete breaking and sand ramming, and in the rotating tools for drilling, reaming, tapping, grinding, buffing, tube expanding and boiler-tube clean ing. Hoists, cranes, jacks and foundry moulding-machines, as well as forging and planishing hammers, resembling steam ham mers in general type, are used in large numbers, and there are also chucks for machine-tools, to grip pieces of work on the move ment of a hand or foot lever. Many actions on machines, which would otherwise be slowly and laboriously performed by hand, are effected in an instant by a pneumatic cylinder. Some kinds of engines, including those for torpedoes and coal-cutters, are air driven, as are locomotives when fire or sparking is inadmissible. In railway service there are the air-brakes and the pneumatic sig nalling and switching apparatus. Large gas and oil engines are started up by a charge of compressed air, while caissons and tunnel shields are worked with its help. Other equipments for which it must be employed are those used in wreck raising and diving. In several industries testing is effected with air, besides inflation and the agitation of liquids.

Air pressures vary from a few to many thousand pounds per square inch. A hand compressor is used for small demands.

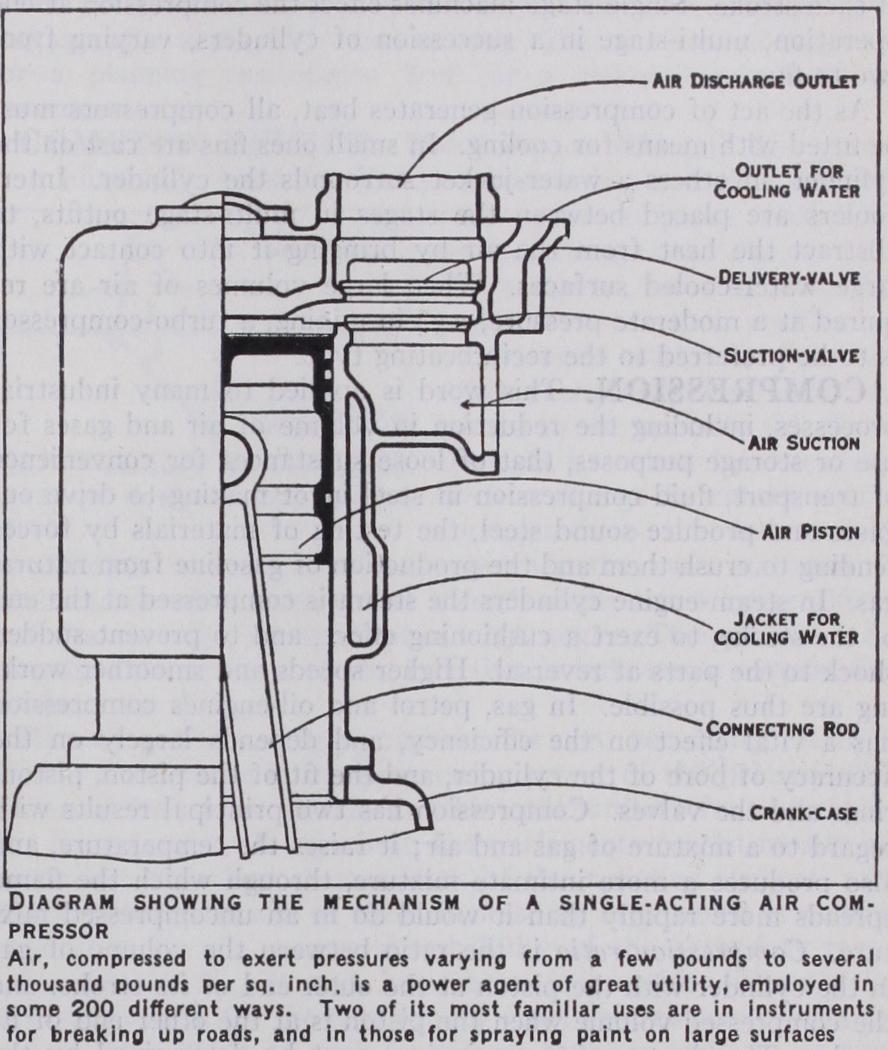

Power-driven machines include those actuated by belt pulley, steam cylinder, electric motor, gas, oil or petrol (gasolene) engine —the last especially for portable outfits for road-breaking. Single acting compressors take in air through an inlet-valve at one stroke of the piston and force it through a discharge-valve to the stor age receiver on the return stroke. This is sketched in the figure. Double-acting compressors have two sets of valves, and deliver air at each stroke. Single-stage machines effect the compression at one operation, multi-stage in a succession of cylinders, varying from two to five.

As the act of compression generates heat, all compressors must be fitted with means for cooling. In small ones fins are cast on the cylinder, in others a water-jacket surrounds the cylinder. Inter coolers are placed between the stages in multi-stage outfits, to abstract the heat from the air by bringing it into contact with large water-cooled surfaces. When large volumes of air are re quired at a moderate pressure, e.g., in mining, a turbo-compressor is to be preferred to the reciprocating type.