Compression

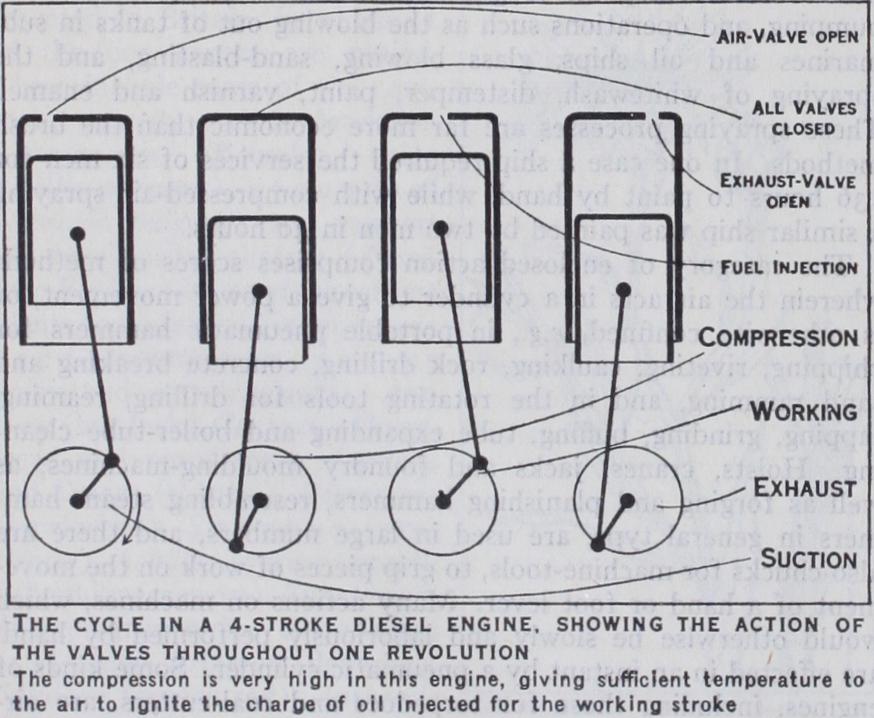

COMPRESSION. This word is applied to many industrial processes, including the reduction in volume of air and gases for use or storage purposes, that of loose substances for convenience of transport, fluid compression in steel ingot making to drive out gases and produce sound steel, the testing of materials by forces tending to crush them and the production of gasoline from natural gas. In steam-engine cylinders the steam is compressed at the end of the stroke, to exert a cushioning effect, and to prevent sudden shock to the parts at reversal. Higher speeds and smoother work ing are thus possible. In gas, petrol and oil-engines compression has a vital effect on the efficiency, and depends largely on the accuracy of bore of the cylinder, and the fit of the piston, piston rings and the valves. Compression has two principal results with regard to a mixture of gas and air; it raises the temperature, and also produces a more intimate mixture, through which the flame spreads more rapidly than it would do in an uncompressed mix ture. Compression ratio is the ratio between the volume of gas in the cylinder with the piston at the outer end of its stroke, and the compressed volume when the piston is at the other end of its stroke. The degree of compression must be determined by the ignition temperature of the charge, which varies in different fuels. For instance, in the cylinder of a gas engine using the ordinary town supply, the pressure ordinarily will not exceed oo lb. per sq.in. Pre-ignition (i.e., ignition during compression stroke) may be due to over-compression, and occurs when a certain supply of gas is changed for another kind, or when the gas comes in contact with overheated parts in the system, or when hot gases from the previous cycle are retained. The greatest pressures are used in the Diesel engine, in order to raise the temperature to a sufficient degree to ignite oil as it is sprayed into the cylinder gradually at the conclusion of the compressive stroke (see fig.). In practice, these range from about 45o to 48o lb. per square inch, the result ant temperature being about i,000°. This is sufficient to cover the requirements for cold starting. A lower pressure can be used when a hot bulb, or similar heating device, is employed; lower compression allows a lighter construction of the engine parts.