Condensed Condenser

CONDENSED CONDENSER, an instrument for compressing air, gas, steam, or a device for concentrating electricity (see p. 2 r6). Condenser also is used in textile work to denote an apparatus which doffs the web from the carding machines and separates it into slivers of soft yard. It is also used in photography as a lens to produce powerful illumination of a slide or other object which is being viewed. A lantern condenser causes light rays to converge after passing through the slide, so that they may also pass through the remaining lenses, which focus the picture on the screen.

Perhaps the best known type of condenser is that used in con nection with steam. James Watt in 1769 first patented a device for the condensation of steam in a vessel separate from the steam cylinder. In the early atmospheric engine a vertical cylinder was open at the top, and the piston was connected by a chain to a pivoted beam, the other end of which worked a pump rod. On admission of steam the piston was pushed up to the top, then steam was turned off, and a spray of cold water thrown on to the piston. The steam in the cylinder condensed, creating a par tial vacuum, with the consequence that the piston was forced down by atmospheric pressure, and became ready for another cycle. The great waste of power due to this alternate heating and cooling of the cylinder led Watt to invent the separate con denser, in which he closed the cylinder at each end, and jacketed it, to conserve the heat. It will be apparent from this that the purpose of a condenser is to create a partial vacuum at the exhaust branch of a prime mover. The air-pump improves this condition by removing air which has leaked into the system. The expansive properties of the steam in the cylinder or turbine are utilized to the best advantage. The vacuum is measured in inches of mercury, and the effect of increase in vacuum is very marked in the case of turbines; thus, an increase of from 27 in. to 29 in. has resulted in some cases in a saving of over 13% in steam con sumption. For reciprocating steam-engines it is not quite so impor tant to attain a high vacuum, because of the limited volume of cylinder space for expansion. Steam condensers are divided into the two main classes of surface and jet condenser.

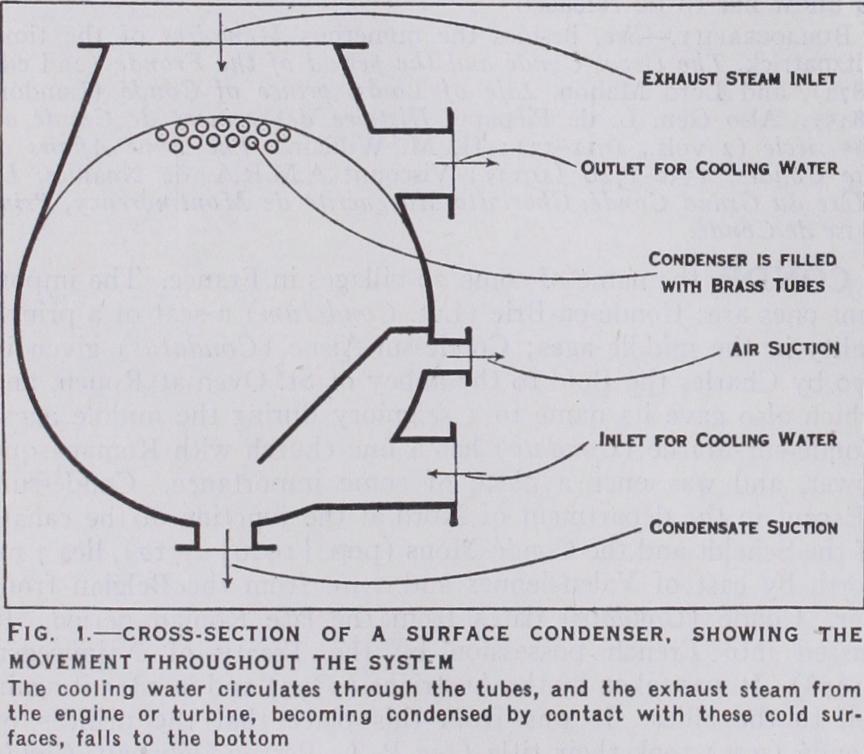

A surface condenser is a vessel filled with brass tubes, passing through plates near the ends ; cooling water circulates through these tubes, and the exhaust steam being admitted becomes con densed by contact with the great number of cold surfaces, and falls to the bottom, being then the condensate, which goes thence into a reservoir termed a hot-well, or is pumped direct to the boiler. The cooling water is dealt with in the manner explained under COOLING SYSTEM. Improvements in the ordinary con denser (fig. 1) are made in several cases, the object being to expose a large area of tubes to the incoming steam. Regenerative condensers are designed so that the temperature of the conden sate does not fall so much as usual; this reduces heat losses caused by the lower boiler-feed temperature.

In a jet condenser the steam and water mingle for the purpose of cooling. The jet condenser may be of three types; the baro metric, siphon or ejector. The ejector condenser (fig. 2) is the simplest in design. A stream of cooling water is discharged• down through a nozzle, and the steam enters a passage at right angles and is directed on to the water by the set of guides—direct conden sation being thus effected. An evaporative condenser comprises a mass of tubes arranged upon a platform or roof ; the steam passes through the numerous tubes, and the cooling water, trickling over their outsides, produces rapid evaporation of the water film and condensation of the steam. Con densers in gas-making practice cool the gas and remove all sub stances which are not permanent gases at normal temperatures. These include atmospheric con densers, which have the exteriors of the tubes through which the gas passes cooled by the air, and water condensers. The latter are supplied with a flow of water sur rounding the gas tubes while in another class the water goes through tubes, and the gas around them. Water-cooling by flow or by submergence in a tank is also done in the case of ammonia and in refrigerating plants. Condensers used in ammonia plants are classified as atmos- pheric, double-pipe and submerged. Other manufactures re quiring the use of condensing apparatus are those of petroleum and perfumes. (F. H.)