Dams

DAMS. From immemorial times dams have been constructed of earth and masonry for the purpose of forming reservoirs for the storage of water to ensure regular supplies to communities for domestic purposes and for irrigation. There are records of a huge earthen dam on the Tigris and a large masonry dam on the river Nile, built almost in prehistoric times, which remained in service for incredibly long periods, and the Romans built numerous mas sive masonry dams in Italy and northern Africa. All the early masonry dams were characterized by excessive width of base usually three to four times the height.

The production of hydro-electric energy and the application of irrigation on a large scale are two forms of development which have expanded very rapidly in the 2oth century in countries having the requisite conditions and resources and in many cases have involved enormously greater storage of water than that required for even the largest towns. The progress in scientific design and in magnitude of dam structures has been correspondingly exten sive, and new types of structure have been introduced to meet the call for greater economy in a class of work which is seldom cheap.

Types of Dams.

The principal types are (a) earth dams, (b) solid masonry or concrete gravity dams, (c) rock-fill dams, (d) single horizontal arch, (e) multiple buttress dams, (f) timber dams, (g) steel dams.While types (a), (b), and (f) have been used from antiquity, the others are products of the 19th and 2oth centuries.

Earth Dams.

Earth dams are largely used on account of their permanence and cheapness and convenience of construction where suitable material is available in the vicinity. Security de pends on the construction being adequately watertight to prevent scouring away of any of the earth by water passing through the dam, and on the installation of a spillway and spillway channel formed in masonry concrete or rock sufficient to pass the maxi mum flood without allowing any water to pass over the top of the earth bank. Water passing over the top would form ruts on the outer slope which would rapidly develop into a breach. Pas sage of water through the dam is usually prevented by the pro vision of a watertight core in the centre of the embankment extending from end to end of the dam and carried down in a trench below the ground surface until an impermeable stratum is reached. Although the best arrangement of materials consists of a core of fine impermeable silt or clay flanked on each side by coarse free draining sand or gravel, dams have been built entirely of fine material when coarse material was unavailable. When built of coarse materials, a central corewall of concrete or steel or an impervious apron on the up-stream face of the dam is required. Corewalls are not now in general use on large dams.The slopes of the embankment vary according to the height of the dam and the nature of the material. Generally the slope next the water is made rather flat, frequently from 1:24 to 1 :3-1 while the outer slope is somewhat steeper, 1:2 to 1:3. In high dams the slopes in the lower part are flattened out still more as compared with the upper part and in all cases the water slope must be protected by stone or concrete paving or beaching suffi ciently massive to withstand wave action and prevent the earth of the embankment from being disturbed.

Earth dams are constructed either by the rolled fill or the hy draulic fill methods. For the former, the material is placed in the dam in layers, each layer being well compacted by special rollers. For the latter, the material is hauled or sluiced to the dam and washed into place, the fines depositing in the centre.

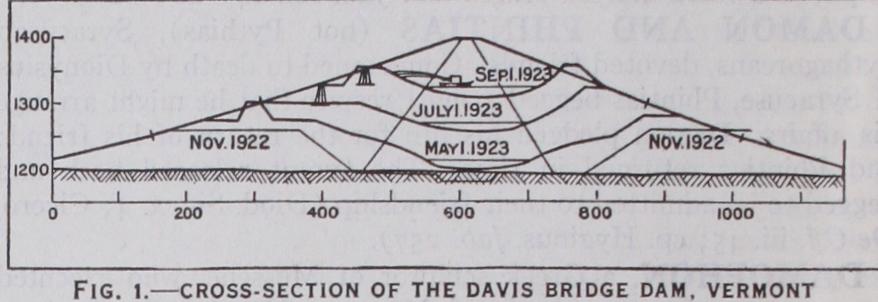

Fig. 1 shows a cross-section of the Davis Bridge hydraulic fill dam in Vermont, 2ooft. high, with an earthworks volume of 1,900,000 cu.yd., which was constructed in less than two years by this method.

Rock-fill Dams.

A rock-fill dam depends for its stability on an embankment of tipped rock material and for its watertightness on a skin of reinforced concrete laid on a derrick-placed or hand built water face and carried down in the form of a vertical cut-off wall to an impervious stratum. Lack of suitable earth material and excessive cost of concrete lead to consideration of the rock fill type of dam. The embankment is usually formed with rock of all sizes as blasted from the quarry, the outer face being roughly built to a plain surface with large blocks and the inner face more carefully and solidly built to a uniform surface and formed with grooves or keyways to furnish a grip for the concrete. Care in constructing the hand-built face reduces somewhat the effect of the considerable settlement which is typical of rock-fill dams following construction. The skin concrete must be well built to withstand this settlement as well as any possible wave action. The water face is steep (sometimes 1:1 or steeper) to minimize the quantity of materials, the outer face being generally somewhat flatter, about I•25 :I or slightly flatter.The largest dam of this type yet constructed is the Salt Springs dam in California, built 1929-31. This has a height of 328ft. and a volume of rock-fill of 3,000,00o cubic yards. The upstream slope averages 1.3:r and is slightly concave to avoid any tendency toward buckling. Downstream, the slope averages 1.4:1. A thick layer on the upstream face was of derrick-placed large stones, while the rest of the material was side-tipped from trains. The watertight skin of reinforced concrete varies in thickness from 'ft. at the top to aft. at the bottom.

Gravity Dams.

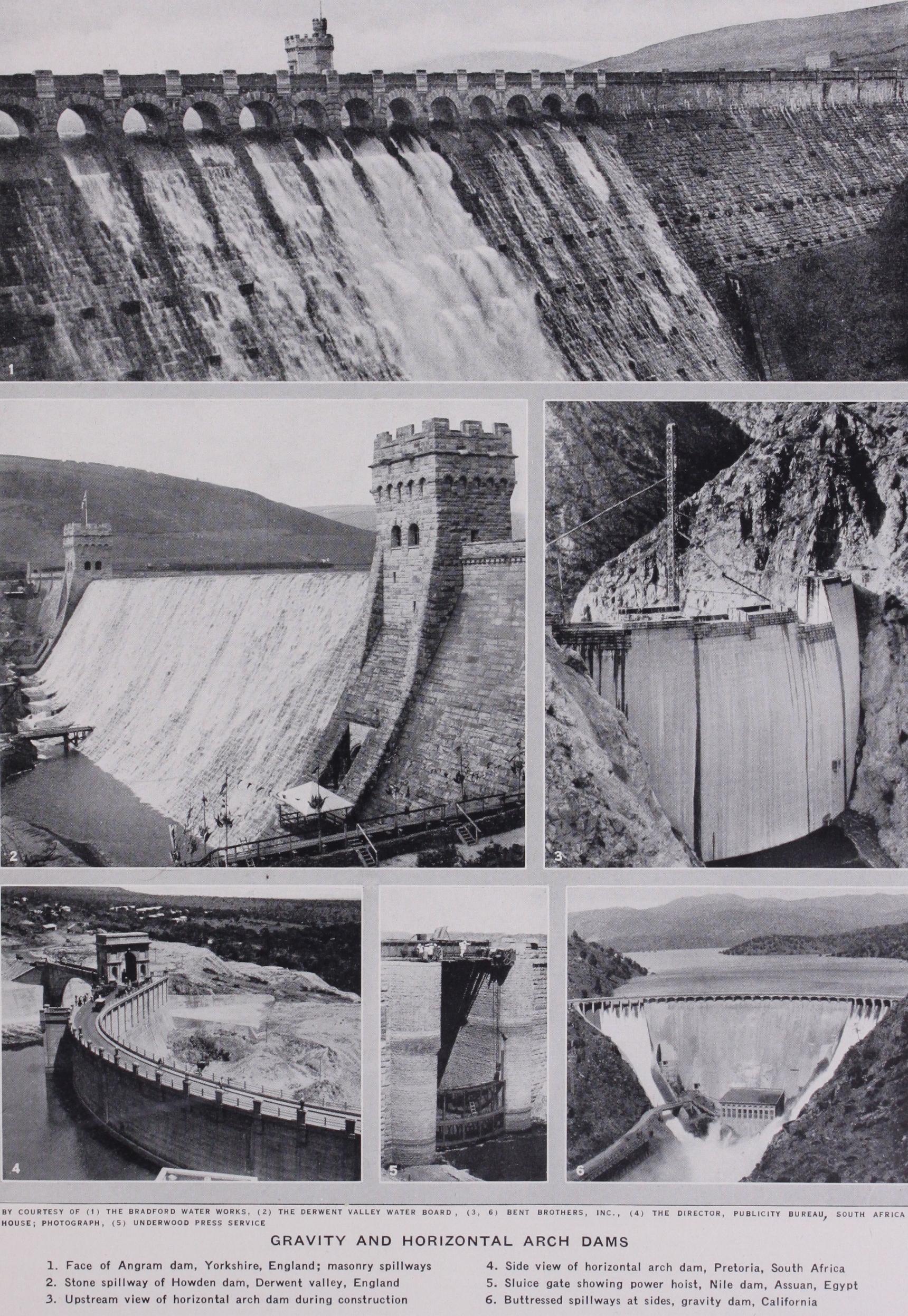

Though dams of massive masonry have been used for thousands of years it was not till the 19th century that a proper scientific basis for design was developed by Prof. Rankine and others so that the width could be reduced from three to four times the height to something less than the height. The tendency in gravity dams is to use the simple triangular form for even the highest dam and to use concrete to the exclusion of masonry. The triangular form gives a uniform stability condition at any hori zontal section, and the maximum stresses in the material are directly proportional to the depth below H.W.L. Assuming a usual inclination of the waterface, say 1:20, and concrete of normal density, the necessary inclination of the outer face will depend on the amount of upward water pressure on the base. If by means of effective drainage arrangements upward pressure is eliminated, an outer slope of about 0.65 :I will suffice. If the conditions require an allowance of upward water pressure on the base varying from the full head at the inner face to zero at the outer face, the outer slope will require to be about 0.8o:I. If, in addition, it is necessary to allow for heavy ice pressure at the top of the wall, still greater slope, up to 0.85:1, will be required. These dimensions ensure that the resultant will pass within the middle third, so that there will be no tension on the concrete. A dam having a height in excess of about 3ooft. requires a flatter face in the lower part in order to spread the footing and keep the intensity of pressures within permissible limits. For some foundation conditions further precaution must be taken to avoid the possibility of the dam sliding on the foundation. For this pur pose keys are constructed on the base of the dam, the depth of the key depending on the condition of the rock in the foundation.

To reduce tendency of the concrete to crack due to temperature changes and shrinkage, modern practice requires as lean a mix of concrete as is practical. However, some specifications require a rich concrete mixture on the outer faces to ensure durability against weathering. The proportion of cement to mixed aggregate may vary from 4 cwt. or less per cu.yd. for the body of the dam to about 5 cwt. on the faces.

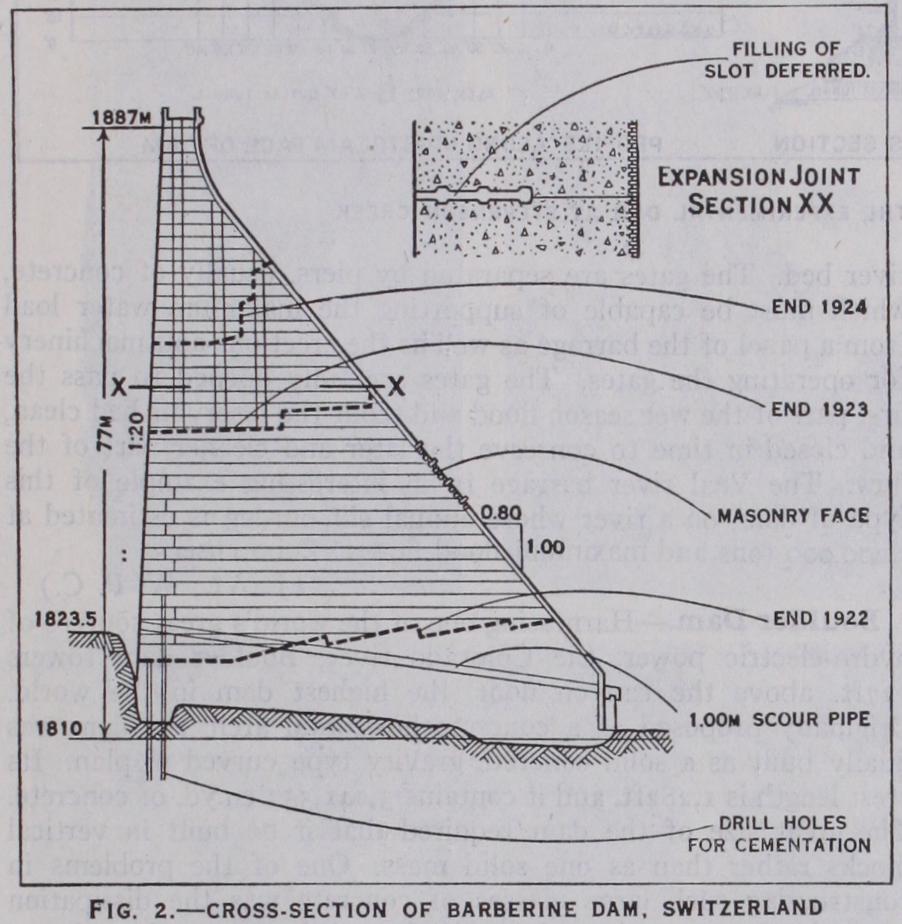

The Barberine dam in Switzerland, completed 1925, and shown in cross section in fig. 2 illustrates the application of the triangular form, together with excellent arrangements for sealing the base by cement grouting in drill holes, and for providing for ex pansion and shrinkage in the upper part. The dam is of concrete with mixtures varying from 250 to 30o kg. of cement per cu.m., is without drainage arrangements and is designed for water uplift on the base varying from full-head at the inside to zero at the outside. The slope of the waterface is 1:2o and of the outer face o.80:1. The section indicates an infrequent masonry facing of gneiss applied on the outer slope, which has a southern exposure and is subject to severe temperature variations.

The highest dam of this type yet projected is the Shasta dam of the Central Valley reclamation project which is to have a maximum height of 56of t., a downstream slope of 0.80 :1 and will contain over 5,500,00o cu.yd. of concrete. The reservoir with a capacity of 4,500,00o ac.ft. will be one of the largest.

Horizontal Arch Dams.

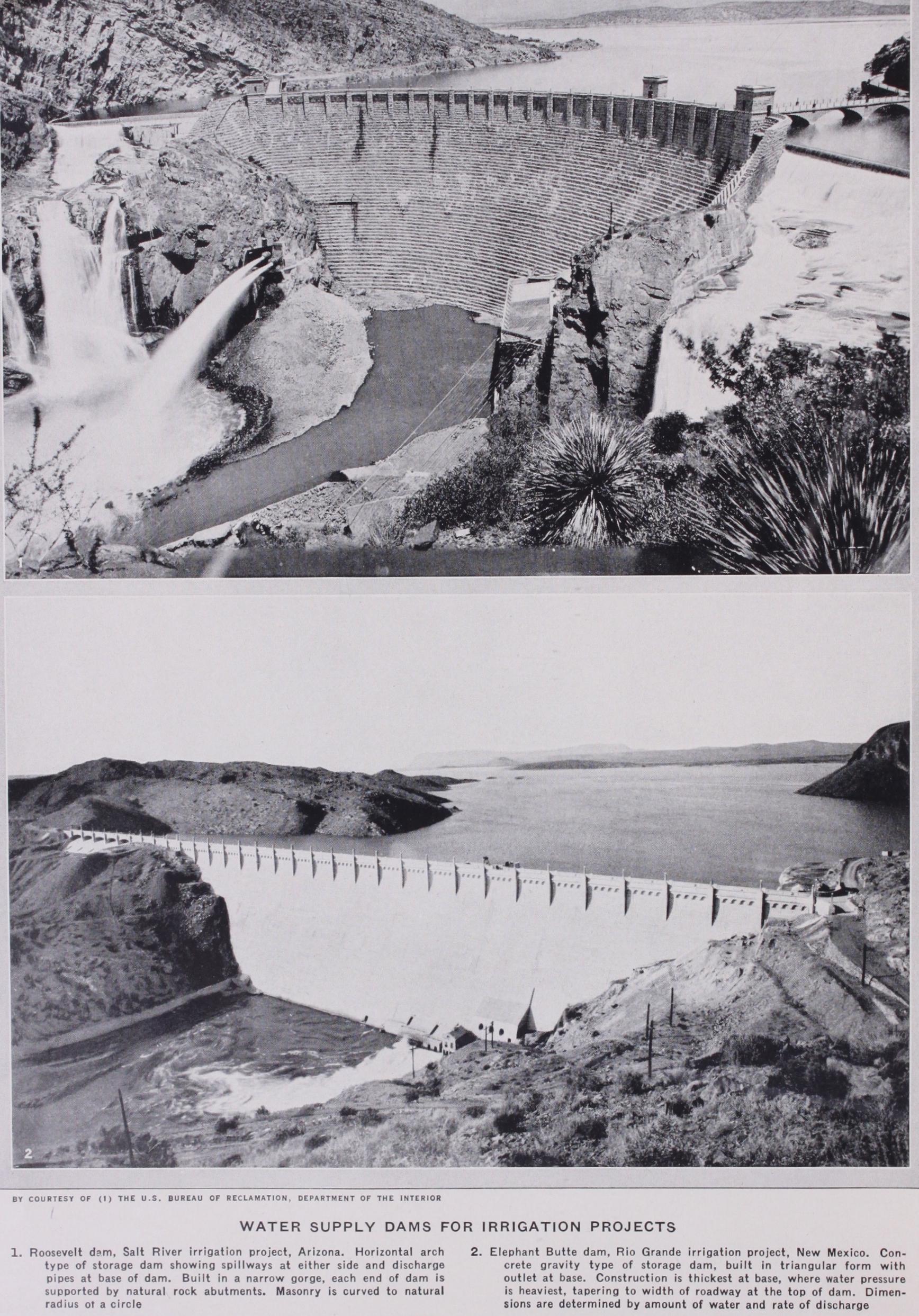

The horizontal arch dam is suitable only for narrow gorges with sound rock at the sides to resist the great thrust from the abutments. Each horizontal section of the dam tends to act as an arch spanning the gorge. The fact that the dam is in contact with the bottom of the gorge alters this tend ency and part of the water load is resisted by a vertical cantilever action. This combined action produces stresses which are exceedingly complicated, and requires for accurate determina tion of stress the use of the trial load method of analysis which necessitates more calculations than any other type of dam. Con siderable information was obtained in 1926 by construction of an experimental arch dam on Stevenson creek, California. A plan, profile, and cross-section of the dam is shown in fig. 5. The thickness of this experimental dam is much less than used for prac tical cases because of the very low safety factor used in its design.The first arch dams were constructed generally with a constant radius throughout, with a resulting variation in the central angle. Increased economy in concrete can be obtained by Jorgensen's constant angle system of construction whereby the radius of the arch increases from the bottom of the dam to the top in accord ance with the varying width of the gorge. The largest dam of this type, constructed in 1934, is the Sautet dam on the Drac river, a tributary of the Rhone river, with a maximum height of 414ft., thickness varying irregularly from 8ft. at the top to 56ft. at the bottom and radius of the water face varying from 23oft. at the top to about 85ft. at the bottom.

Multiple Buttress Dams.

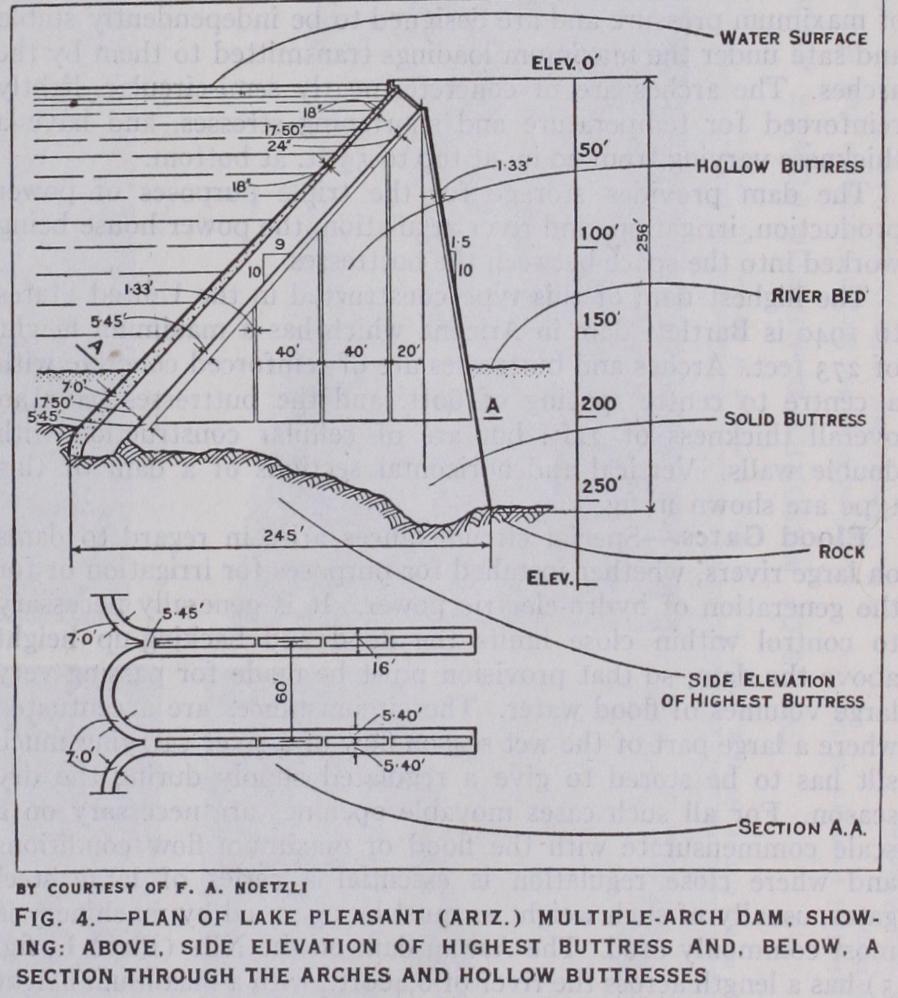

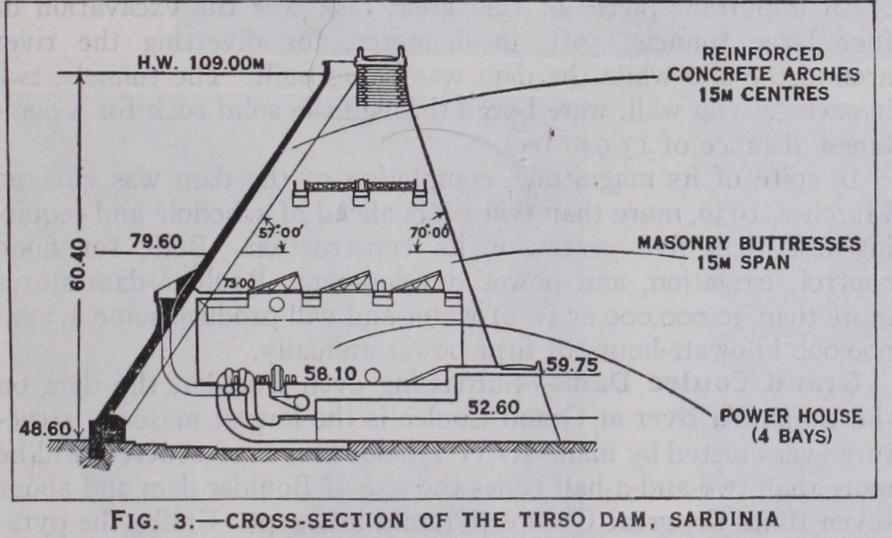

In multiple buttress dams the water load may be supported and transferred to the buttresses either by reinforced flat slabs or by arches. With flat-slab con struction a spillway section can readily be formed by providing flat slabs also on the outer face, formed to a suitable spillway curve. The Junction Brook main dam of the Newfoundland Power and Paper Company is of this type and about ,000 f t. long and 75 ft. high and carries a single-line railway. The buttresses, spaced at 18 ft. centres, are of plain concrete from 16 in. to 44 in. thick. The slabs vary from 16 in. to 47 in. in thickness and are heavily reinforced as simple beams to support the water pressure. Flat slabs form an uneconomical type of construction for support of heavy water pressures as compared with arches and entail a multiplicity of buttresses with close spacing, the practicable maxi mum being about 20 feet.In multiple arch dams the buttress spacing may be from 15 to 6o ft. depending on the general height of the dam. The highest multiple arch dam constructed in Europe to 194o is the Tirso dam in Sardinia. The buttresses, spaced at 5o ft. centres, are of masonry with courses sloped at the outer face to suit the direction of maximum pressure and are designed to be independently stable and safe under the maximum loadings transmitted to them by the arches. The arches are of concrete, nearly semi-circular, lightly reinforced for temperature and shortening stresses, and have a thickness varying from 20 in. at top to 54 ft. at bottom.

The dam provides storage for the triple purposes of power production, irrigation, and river regulation, the power house being worked into the space between the buttresses.

The highest dam of this type constructed in the United States to 194o is Bartlett dam in Arizona which has a maximum height of 273 feet. Arches and buttresses are of reinforced concrete with a centre to centre spacing of 6oft. and the buttresses have an overall thickness of 22ft. but are of cellular construction with double walls. Vertical and horizontal sections of a dam of this type are shown in fig. 4.

Flood Gates.

Special circumstances arise in regard to dams on large rivers, whether installed for purposes for irrigation or for the generation of hydro-electric power. It is generally necessary to control within close limits the flood and backing-up height above the dam, so that provision must be made for passing very large volumes of flood water. The circumstances are accentuated where a large part of the wet season flow of a river can-ying much silt has to be stored to give a regulated supply during the dry season. For all such cases movable openings are necessary on a scale commensurate with the flood or maximum flow conditions and where close regulation is essential a series of large steel gates, usually of such weight as must be operated by machinery is most commonly used. The Aswan dam on the Nile (Plate I., fig. 5) has a length across the river of 6,400ft., with a maximum height of 175ft. and forms an irrigation storage reservoir with a capacity of over 4,000,000 acre feet. Water is shown being discharged from several of the many large sluice openings.The Dnieprostroy dam on the Dnieper river, built for the Soviet Government, is the largest low head dam in the world constructed for hydro-electric power purposes. Gate and spillway arrangements are provided on a scale sufficient to pass a flood of 1,25o,000 cusecs. Power can be developed up to 56o,000 kw.

For the extreme case of a river transporting great quantities of silt where the barrage must not be allowed to become a trap for the settlement and accumulation of large quantities of material brought down during high floods, a continuous series of gates is used extending from bank to bank and having their sills at the river bed. The gates are separated by piers, usually of concrete, which must be capable of supporting the maximum water load from a panel of the barrage as well as the erections and machinery for operating the gates. The gates are fully opened to pass the first part of the wet season flood and scour the reservoir bed clean, and closed in time to conserve the later and cleaner part of the flow. The Vaal river barrage is an interesting example of this type of dam, on a river whose annual silt burden is estimated at 1,200,000 tons and maximum flood flow 187,000 cusecs.

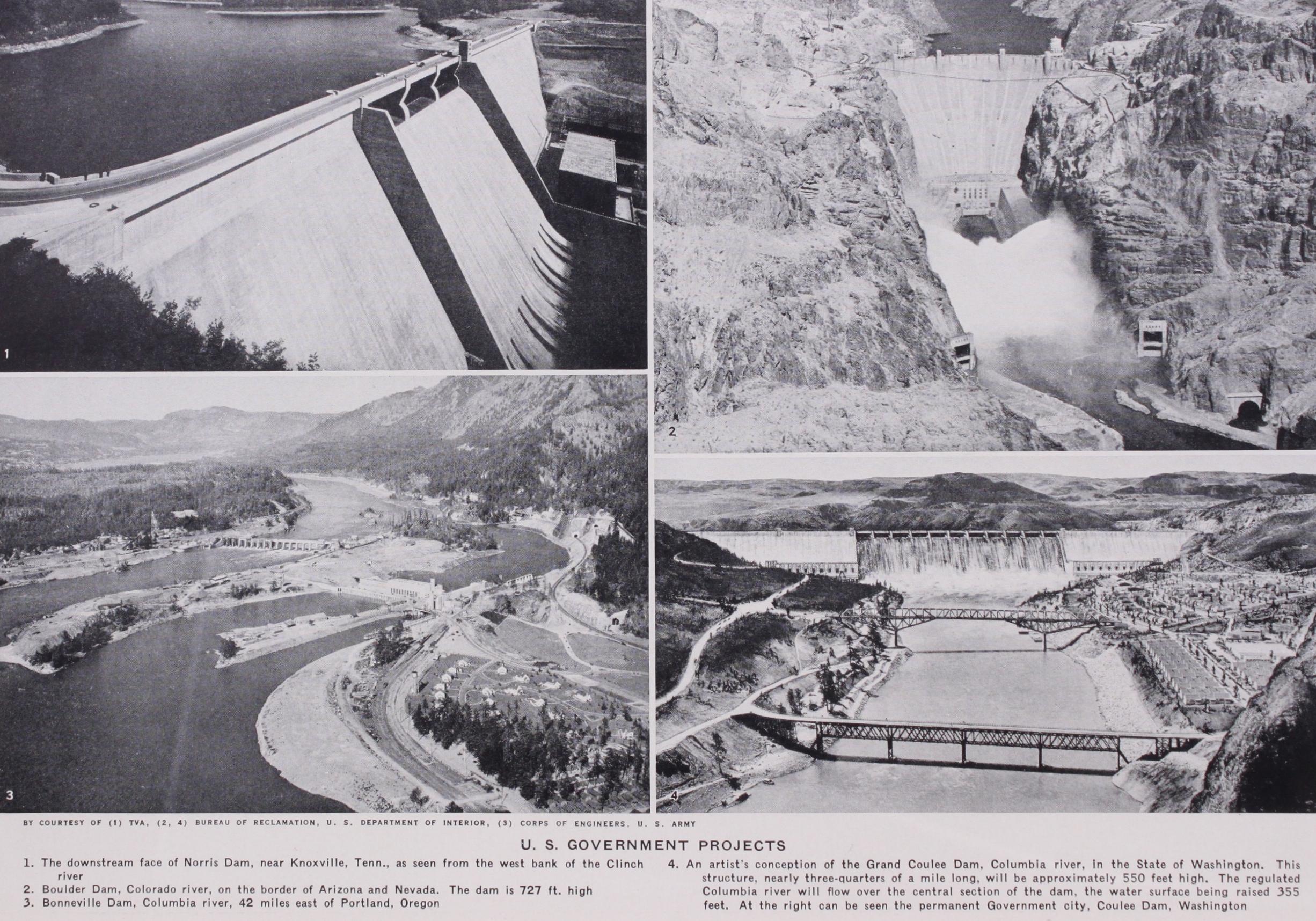

(J. WI.; W. P. C.) Boulder Dam.—Harnessing one of the world's great sources of hydro-electric power, the Colorado river, Boulder dam towers 727ft. above the canyon floor, the highest dam in the world. Originally proposed as a concrete horizontal arch, the dam was finally built as a solid concrete gravity type curved in plan. Its crest length is 1,282ft. and it contains 3,241,553 cu.yd. of concrete. The great size of the dam required that it be built in vertical blocks rather than as one solid mass. One of the problems in constructing such large masses of concrete was the dissipation of the heat generated by the hydration of the cement in order to prevent any large amount of expansion and contraction after the concrete had taken its initial set. For this purpose more than 57omi. of in. tubing were buried in the concrete and refrigerated water pumped through them.

The concrete for the dam was supplied by eight mixers, each with a capacity of four cubic yards. These were located in two plants, one in the canyon for the lower half of the structure, and the other on the canyon rim for the remainder. Construction was facilitated by the erection of a huge cableway suspended over the site for transfer of concrete and other construction materials to all parts of the dam.

An important phase of this great task was the excavation of four large tunnels, soft. in diameter, for diverting the river around the site while the dam was being built. The tunnels, two in each canyon wall, were bored through the solid rock for a com bined distance of 15,946 feet.

In spite of its magnitude, completion of the dam was effected March 1, 1936, more than two years ahead of schedule and requir ing less than five years for its construction. Built for flood control, irrigation, and power development, Boulder dam stores more than 3o,000,000 ac.ft. of water and will produce some 4,33o, 000,000 kilowatt-hours of firm power annually.

Grand Coulee Dam.

Surpassing even Boulder, the dam on the Columbia river at Grand Coulee is the largest masonry struc ture ever erected by man. Its I1,25o,000 cu.yd. of concrete will be more than two-and-a-half times the size of Boulder dam and about seven times the great Cheops pyramid in Egypt. Unlike the pyra mids, however, this structure is conceived as a great social bene fit. Some o,000 families will find new homes on the 1,200,000 acres which will be irrigated by the great dam.Grand Coulee dam is situated at a point where a glacier once dammed up the river forcing it to find a new course. Later the glacier receded and the river returned to its original bed 600ft. below, leaving a dry canyon somi. long and 2 to 5 mi. wide, now known as Grand Coulee. Part of the hydro-electric power gener ated at this dam will be used to pump water from the reservoir be hind the dam into another reservoir which will be created in the upper end of the Grand Coulee by constructing two earth and rock fill dams across it. This will involve lifting the water a maximum of about 37o feet. From this reservoir the water will flow through approximately 25omi. of main canal to irrigate the fertile basin of the Columbia river in the area known as the Big Bend. The Grand Coulee dam is 5 5of t. high, with a base width of 48oft. at its maximum section. Its total length is 4,5ooft. with 1,65oft. of this used as a spillway capable of passing a flood of i,000,000 cu.ft. per second. Such a flood would create a fall of water 5 times the average flow of Niagara Falls and 3 times as high.

The tremendous size of the dam presented the same construction problems as did Boulder, with the dam built in individual verti cal blocks, usually about 50f t. square. Cooling water was circu lated through 2,2oomi. of 1 in. tubing. A unique construction fea ture was the use of a system of long conveyor belts to transport materials from the excavation and to deliver concrete aggregates.

Assisting materially in flood control and river regulation, Grand Coulee dam has a storage capacity of 9,610,000 acre feet. Ulti mately nine generators will be housed in each of the two power plants at the dam. Their total capacity will be 2,550,000 horse power. The energy from six of the generators in the plant on the west side of the river is to be used for pumping. The remainder is to be sold to the market that is expected to develop when the irrigated land comes into use. The generators are expected to produce over 8,1 oo,000,000 kilowatt-hours of firm power annually.

Fort Peck Dam.

The largest dam in the world, Fort Peck, be gun in 1934 and requiring six years for completion, is on the Missouri river in Montana. Built for purposes of flood control and power development, it has a maximum height of 242ft., a crest length of 9,000ft. and contains 1 oo,000,000 cu.yd. of earth fill placed hydraulically. Four large dredges were built at the dam for purposes of dredging material from the valley bottom and pumping it into place on the dam through steel pipe lines 28in. in diameter and 5mi. long at certain stages of construction.On Sept. 22, 1938, with over 95% of the fill completed, there occurred a considerable movement of the material in the upstream face of the dam near the east abutment, involving approximately 5,000,00o cu.yd. of fill. The damaged portion was entirely re moved and rebuilt causing a delay of over a year in the final corn pletion time of the structure.

Fort Peck will store 19,500,000 ac.ft. of water, exceeded only by Lake Mead, the storage reservoir created by Boulder darn.

Timber and Steel Dams.

Mention should be made of the relatively less important dams of steel and timber. The former type is in general similar to the multiple buttress type of concrete darn previously described, in that the water load is supported by steel decks resting on steel frames. Timber darns are sometimes built in the same manner but more frequently are rock filled cribs with timber decks. They are numerous but usually quite small and often only temporary, as for some major logging operation or for a cofferdam. Few steel darns have been built, probably due to lack of confidence in their permanence. Three large steel darns were constructed about 1900, but after one of these failed, al though its destruction was attributed to a foundation failure and not in any way connected with the fact that it was built of steel, it was replaced by a concrete darn and since then none of any im portance has been erected.