Disintegrator

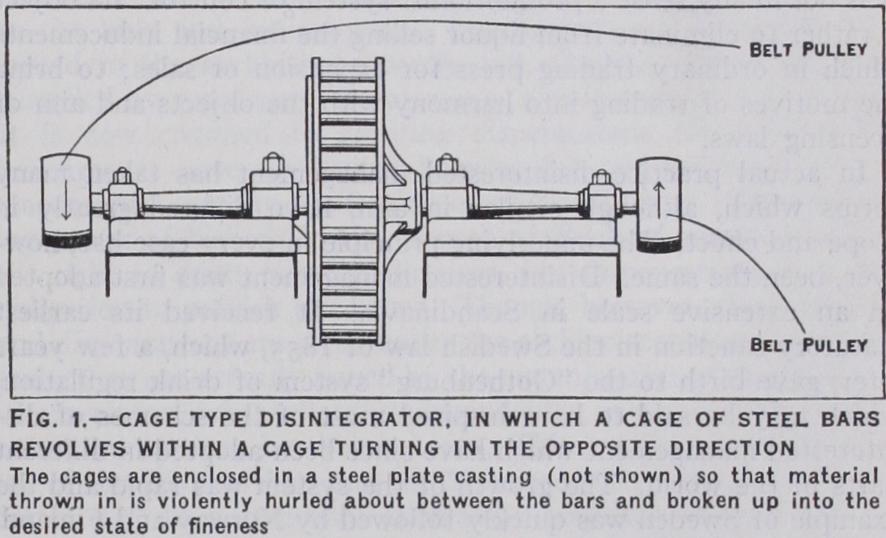

DISINTEGRATOR. A term rather loosely used, but gen erally applied to a machine which breaks up and reduces materials by impact, as distinct from one which grinds between rollers, or amongst a mass of loose balls in a rotating drum. There are two main classes of disintegrators : the cage or reel and the hammer types, the latter being the more powerful. Among the substances broken up and ground more or less finely in disintegrators are coal, coke, slag, sand, shale, chalk, limestone, pitch, plaster, starch, clay, shells, gypsum, barytes, rock salt, glue, bark, soap, bones, fer tilizers, cattle foods, brick-bats, stone, limestone, iron oxide, li noleum colours, printer's ink and other products. The more fibrous materials such as bark, rubber, asbestos, leather, herbs, etc., may be shredded up by a machine consisting of a set of revolving knives flying past a set of stationary ones, but in other cases pure impact is the disintegrating medium. The cage machines have a couple of cages, one within the other, composed of steel bars or beaters, which revolve in opposite directions (fig. I.). The figure shows the machine with the casing removed; when the stuff is fed through a hopper, it is thrown with great violence amongst the bars and broken up. The speed of revolution ranges in various machines from 30o to 2,000 revolutions per minute. For fine dis integration a machine with duplicated sets of cages is employed.

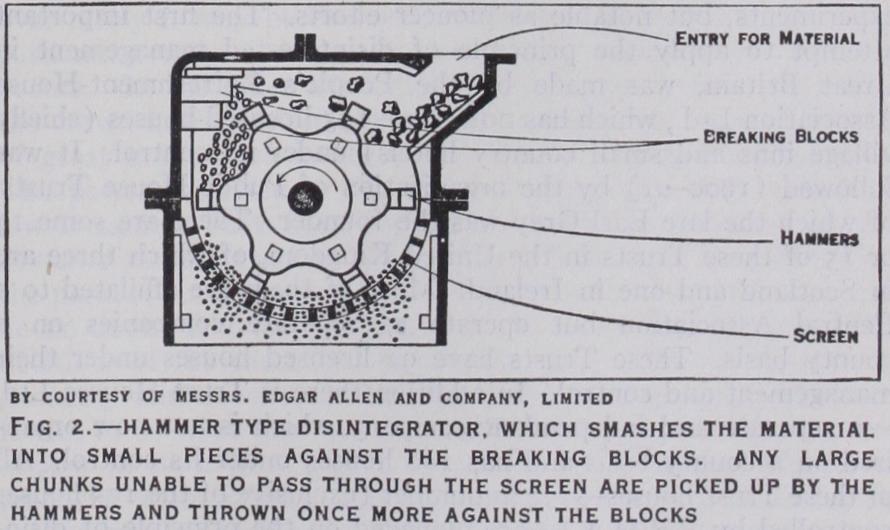

Hammer or beater machines consist of a revolving set of swing hammers which beat the material small within the casing. The disintegrating action may occur while the material is "in the air," or when it is smashed against steel blocks within the strongly built casing. Fig. 2 shows the latter action; as the hammers whirl round at about a thousand revolutions a minute they catch the stuff fed into the hopper and hurl it against the blocks, the rebound being caught by succeeding hammers ; and the material is finally reduced to the fineness required before it can pass through the screen. The inside of the machine is lined with steel plates which can be renewed when worn through. Some machines are built with a pocket into which fall any odd pieces of iron (termed tramp iron) which accidentally get in with the material. This safety device prevents serious damage to the various parts of the mill. A big crusher will break up 7oo tons of limestone in the hour.