Jidda

jig, jigs, metal, box and holes

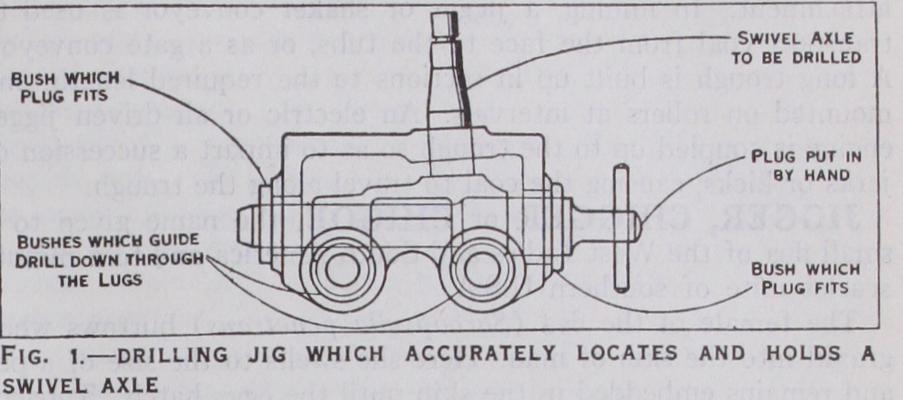

Jigs may be of plate or open type, or of box type. The former are simple and suited to many of the flatter objects, or those which need drilling on a top face, from which the jig plate can be set by its ledges embracing the sides. A box jig surrounds the casting or forging, and locates by several spots, while a hinged cover is often fitted rapidly to release the piece and to put a fresh one in. Sometimes the location is effected by means of a part already machined instead of from a rough untooled portion, either a flat, or a cylindrical, or a bored hole. Fig. i shows this feature in regard to a familiar motor car detail, the swivel-axle, the box jig taking the turned part through a hole at the back, and locating the main holes by a long mandrel passed through. Then the two holes are drilled with the bushes for guides. Many jigs are built to turn over on to various faces so as to drill holes from each side, or may swivel on trunnions for a similar reason. With a conveyor system running past the machines, as in car factories, the jigs are mounted on wheels.

Fixtures are used in the lathe, planer, shaper, slotter, miller, grinder, gear-cutter, also on broaching machines, and frequently for use in assembling mechanisms quickly. The clamping arrange ments have to be devised for quickness, and in some cases auto matic clamps are fitted which loosen and tighten at the correct periods.

Other jigs which are not concerned with cutting processes in clude those for holding articles in correct position for soldering or brazing, and the moulds which hold connecting-rods and bear ings while being run up with white metal. Forms vary according to the shape of the work, but an angle-plate shape, seen in fig. 2, is suitable to clamp a half-bearing against the upright face, while a half-mandrel of appropriate radius is bolted also, leaving a space for the white metal to run into, so forming a new bearing surface.

Jig refers also to a reciprocat ing movement, such as that of a jig-saw which operates similarly to a fret-saw, and is designed either for wood or metal, in the latter case being much used for cutting dies. A jigging screen also possesses the to and fro ac tion necessary to keep material in motion while being separated or sifted. The jig for concen trating minerals consists of a series of boxes with a shaft running above and having eccentrics that impart the jigging motion. A water supply is provided. Diamonds and other precious stones are recovered in this kind of jig. (F. H.) JIG, a brisk lively dance, the quick and irregular steps of which have varied at different times and in the various countries in which it has been danced (see DANCE). The music of the "jig," or such as is written in its rhythm, is in various times and has been used frequently to finish a suite, e.g., by Bach and Handel. The word has usually been derived from or connected with Fr. gigue, Ital. gigs, Ger. Geige, a fiddle. The idea of jumping, jerk ing movement has given rise to many applications of "jig" and its derivative "jigger" to mechanical and other devices, such as the machine used for separating the heavier metal-bearing por tions from the lighter parts in ore-dressing. The word "jigger," a corruption of the West Indian chigoe, is also used as the name of a species of flea, the Sarcopsylla penetrans, which burrows and lays its eggs in the human foot, generally under the toe nails, and causes great swelling and irritation (see FLEA).