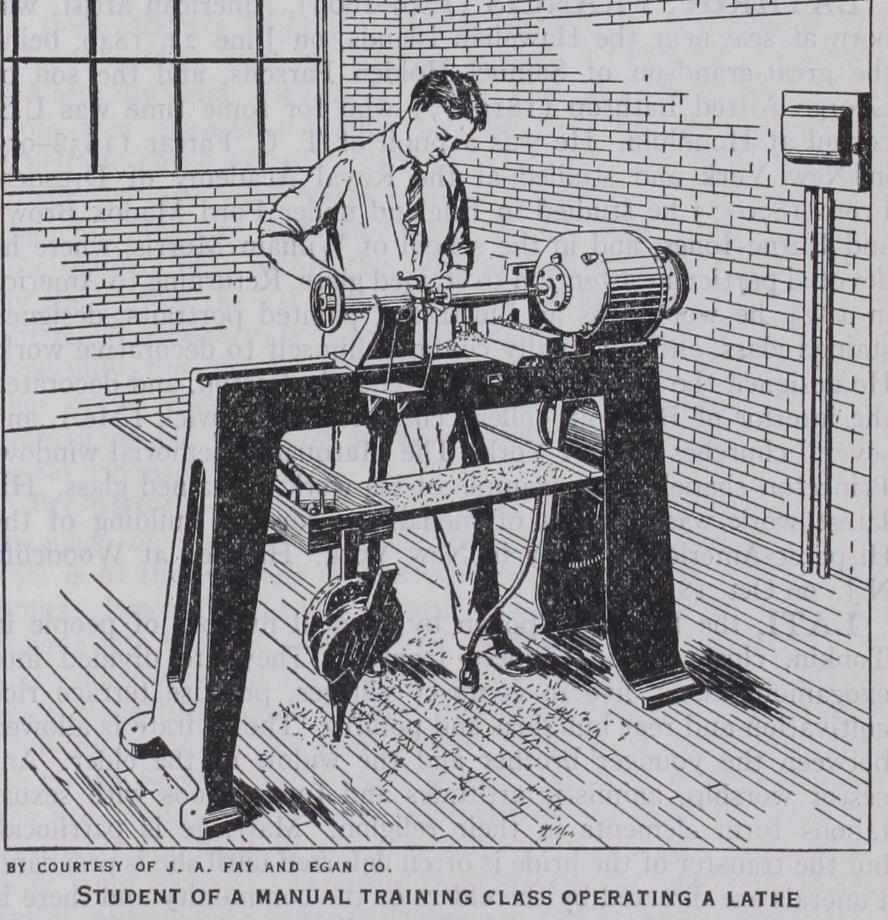

Lathe

lathes, chuck, tools, wheels, boring, automatic, cut, wood, tool and articles

LATHE is a machine for holding securely and rotating a piece of wood, metal or other material, in order that it may be cut, scraped, or polished by the turning. The primitive lathe consists of two tree trunks, each holding a pointed centre, between which a cylinder of wood is spun while a tool is held to cut it to shape. This elementary type has been in use in the East since remote times and may still be seen at work in India. An assistant imparts a to and fro motion to the wood by pulling alternately at the ends of a cord wound round it. The turner holds the turning tool between his toes and controls it with his hands.

All modern lathes have a continuous rotation (with the excep tion of the little ones used in watch-making) and the power is received from a treadle or prime mover. The usual method is to rotate the mandrel or spindle of the headstock, and cause this to turn the work by a driver or a chuck. Articles such as disks and wheels, that cannot be mounted between the centres, are held on a faceplate or in a chuck, the resemblance to the potter's wheel being obvious. The biggest lathes, for gun and marine work, will take pieces ioo feet long; and the chuck will carry a weight of Doc) tons in its jaws. The number of tools used in a modern metal-turning lathe varies. Hand tools are still used in small lathes for wood and metal turning, but the slide-rest has practi cally displaced these. It holds the tool or tools rigidly and gives a controlled movement in the direction required to produce a parallel cylinder, a taper, or a flat face, or to bore a hole. Handles effect the movement, or an automatic feed is derived from the drive. If a long screw is fitted, and connected to the spindle with appro priately chosen toothed gears, called change-wheels, the slide can be caused to travel at a definite rate in regard to the number of turns of the work, and so to cut a true screw upon it. In some turning operations, the operator has constantly to manipulate the handles so as to guide the tool into the necessary paths, while in other cases the lathe may be set up and the automatic feed thrown into action so that no attention is required for some time.

The widely-varying requirements of watchmakers, engineers, etc., have resulted ir. the development of numerous types of lathe. The watchmaker's lathe is finely built, and many other processes besides simple turning and boring are accomplished, with the help of special attachments; e.g., drilling, milling, gear tooth cutting, grinding, polishing. The bench lathe is also a small high-precision design of rather larger size, and capable of an even greater variety of operations ; it is used by the makers of fine instruments, tools, gauges and small mechanisms. Plain or simple lathes may be worked by boys or girls on repetition articles, for turning, boring, drilling, etc., at a great rate of output. The more complicated lathes employed for a varied range of processes are termed engine lathes (see the diagram), and possess the full equipment of chucks and fittings, a wide range of speeds, and automatic feeds as well as the screw-cutting apparatus mentioned. These are made in all sizes ; one, of moderate size and great pre cision, and with additional devices for use in the preparation of tools and cutters, is called a tool-room lathe, and it cuts very accurate screws. The high-precision screw-cutting lathe prepares

screws possessing the utmost possible degree of accuracy.

Large lathes for turning shafting, pulleys, wheels, etc., required in various engineering construction are made in varied designs. Shafting lathes turn long shafts rapidly, and have multiple tools which cut at the front and the rear, the shaft being supported in steadies to prevent it from running out of true. The gun lathes are big and have numerous tool-rests, some being arranged for the deep boring of the tubes. In railway works the axle-turning lathes are important ; they deal with the two journals of the axle simultaneously. Locomotive and tramcar wheels are also bored and turned on lathes made specially for the purpose, these dealing with two wheels on separate chucks, or wheels mounted on the axle. Surfacing and boring lathes are relatively short, and deal with wheels, disks, pulleys, flywheels, gear blanks, and many flat castings which do not require support other than that of the chuck jaws. A gap in front of the chuck enables extra large diameters to be "swung," this gap being sometimes a pit in the floor ; this type is classed as a face lathe. The inconvenience of attempting to fasten heavy pieces to a chuck with vertical face has led to the development of the turning and boring mills or vertical lathes. The chuck spindle is vertical and the horizontal face of the chuck consequently renders work setting easy. The advantages have become so• obvious that many sizes of these machines are now employed extensively for flywheels, gear wheels, pistons, covers, and other parts of engines and machines.

Capstan or turret lathes possess modified tool-rests. Instead of taking one or two tools in a constant position, the turret holds a set for numerous processes, and any one of them can be swung round to cut the work. Hence a set of operations may be effected in rapid succession, or if a piece of bar is held in the chuck, screws, bolts, pins, nuts, washers and a host of other articles can be machined and parted off, the bar being fed through for another cycle. When a turret lathe for dealing with bars is actuated entirely by automatic means instead of by an operator manipulating various levers, it is called an automatic screw machine. If it deals with separate pieces gripped in the chuck in succession, it is termed an auto turning lathe (see AUTOMATId MACHINES). Lathes in which there is no actual turning action include the spinning and the polishing lathes. The first shapes sheet-metal pieces by the pressure of hard steel tools or rollers, and is used to produce parts of silver and gold ware, tin, brass, aluminium domestic and other articles. Sometimes spinning is an alternative to stamping in dies, sometimes it is also used to smooth out the creases made when cup-shaped stampings are done in dies. The polishing lathe is just a head which carries a spindle run at very high speed, and drives the polishing agent, which is a leather wheel or a cotton bob or mop. (F. H.)