Locomotive Coaling

coal, plant, wagons, conveyor, fig, bunkers, type, installation, crane and wagon

Coal in Overhead Bunkers.

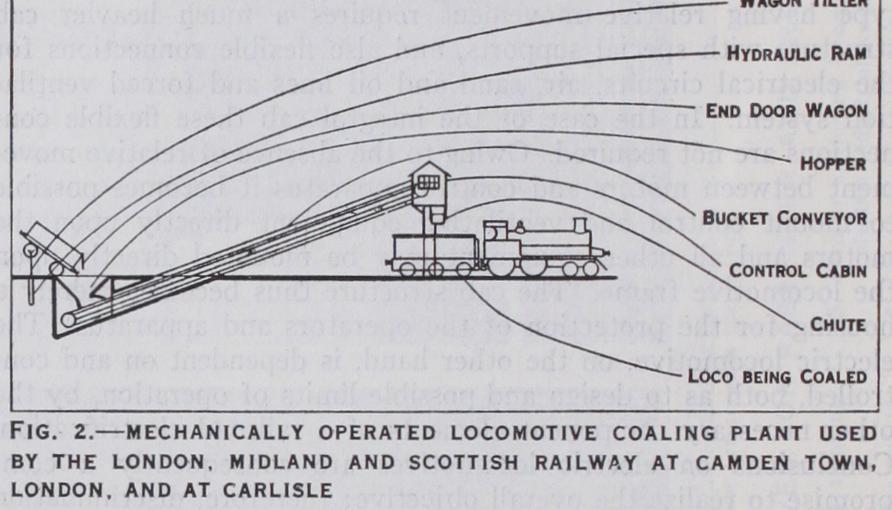

With this plant a wagon tippler is used, and several methods are employed for raising the coal to the bunkers ; viz., inclined hand conveyors, bucket con veyors and skip hoists. (See MECHANICAL HANDLING.) The latter are not, however, used in this country so much as they might be, though in America they are most usually employed.

Since such coaling installations have also to include a device for unloading the coal from the truck before it can be fed on to a conveyor or skip hoist, a system has been evolved for use where large capacities are concerned, in which a wagon tippler is so modified that a full coal truck can be lifted bodily off the rails to a level well above the bunkers, tipped and returned empty to the rails, thereby dispensing with conveyors. Such devices are, as a matter of fact, modifications of a type of wagon tippler.

In the following examples handling methods as enumerated in the foregoing are employed.

The locomotive coaling plant of the L.N.E.R. Rly. at Strat ford, is the only installation of the kind in this country where a band conveyor is employed. It consists of a wagon tippler which discharges into an under-rail hopper which, in turn, feeds a band conveyor 277 ft. long, disposed at an incline of about 2o°, which delivers the load at a height of 64 ft. above the rails into an over head bunker of reinforced con crete, 120 ft. long and 45 ft. wide, which has a capacity of Boo tons.

It is provided with 16 shoots, eight for each road, one on either side. These provide fuel for 400 locomotives per day, at the rate of 600 to 700 tons of coal.

Less than two minutes is taken to coal one locomotive. The plant was installed by Messrs. Fraser & Chalmers, of Erith.

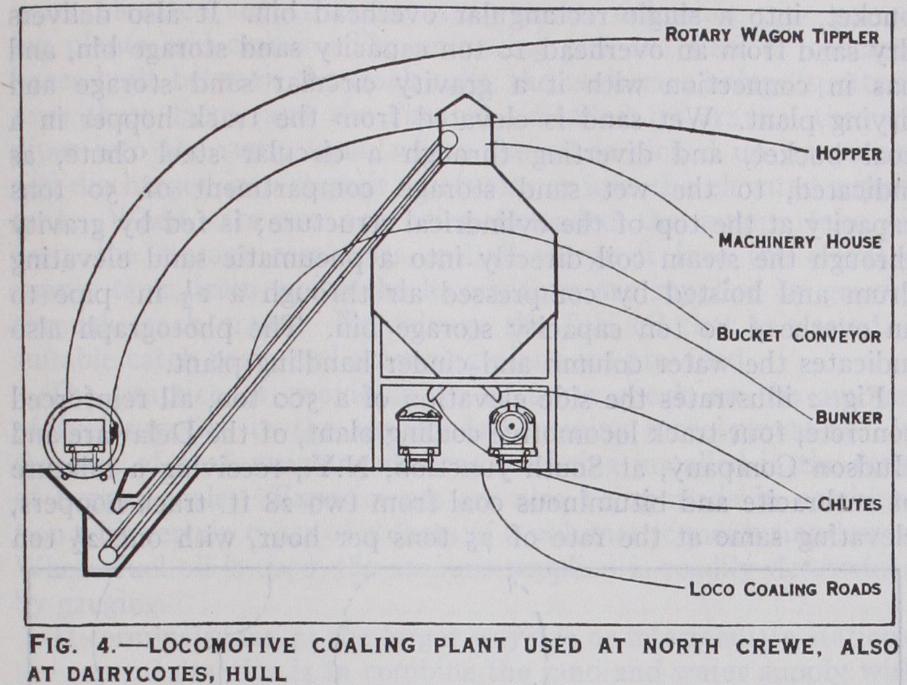

In fig. 4 is shown a diagram matic representation of the type of locomotive coaling installation employed at North Crewe and at Dairycotes, Hull. In this a bucket conveyor is used for rais ing coal to the bunker. The manufacturers of this are Messrs. Spencer (Melksham) Ltd., Melksham, Wilts.

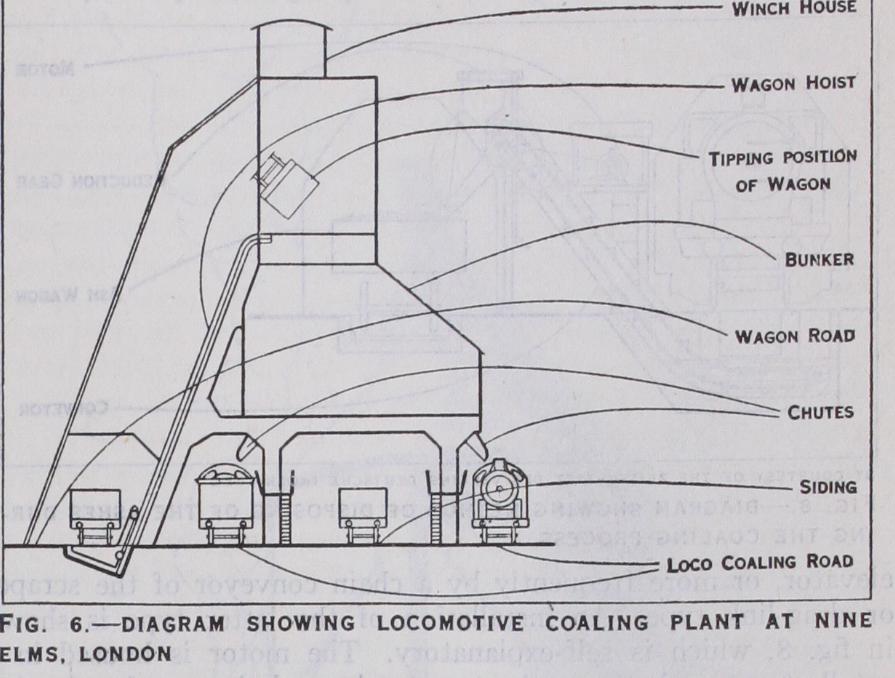

All the latest coaling plant in Great Britain is of the type in which a modification of side discharging wagon tipplers are em ployed (see fig. 5), which represents the plant at South Crewe, where the wagons are lifted vertically, while fig. 6 is a diagram matic representation of the Nine Elms plant, in which the path of the rising wagons is steeply inclined. These installations were both built by The Mitchell Conveyor & Transporter Co. Ltd.

A coaling plant which is unique on account of its simplicity and efficiency is that used by the L.M.S. Rly Co. at their Edgehill depot. Topographical conditions being favourable, no conveyors are needed to fill the the coal being handled by gravity with the exception of the use of a few capstans for the purpose of marshalling the wagons in position for unloading into the bunkers. Full wagons are brought along an overhead ramp and subsequently transferred to a spur track with two lines, one for the full, the other for the empty trucks ; these traverse the length of a set of three concrete bunkers, into which the wagons are unloaded and over which the lines terminate. The empties are returned on a track with a gradient of i : 50. Each of the three

bunkers holds 4o tons, with a maximum of 45. Each bunker has two outlets at a sufficient level above the engines and provided with feeding spouts, thus serving two lines, one on each side of the staging. The coal is transferred through a measuring shoot which doles it out in half-ton charges, merely by the manipulation of two levers.

Ground Storage "Bings..

The advantage of this type is that the wagons are not kept idle while they serve as storage recepta cles. It is much used in Germany in conjunction with a crane and grab installation, for the purpose of coaling tenders. Such a system is shown diagrammatically in fig. 7. A travelling bridge gantry straddles a coal bing; on this the travelling crane is mounted so that it can reach both extreme positions over two rail roads, the inner ones for the locomotive and the two outer ones for the coal trucks. The bing can be accumulated by the crane from trucks on the outer roads, or from the trucks on a raised central track. The gantry is provided with two bunkers holding 15o tons each; these are kept full by the crane and the tender is coaled merely by lowering the bunker outlet. Pits be tween the outer and inner tracks (see fig. 7) are provided for the reception of ashes and clinkers, which are raked out during the coaling process and are likewise disposed of by the crane combina tion at intervals. The only drawback to this otherwise efficient installation is the grab. As a matter of fact grabs are not really suitable for discharging railway wagons. If large they are apt to damage the wagons, and in any case, much hand trimming is necessary.

In order to omit nothing appertaining to the subject, it should be mentioned that, during the time occupied in coaling locomotives, particularly in large yards, it is sometimes essential to provide appliances for the removal of ashes and soot, and the provision of dry sand. In such cases the ashes are generally raked out and dropped into a pit beneath the rails, which contains quench ing water ; from there they are raised by a grab, skip hoist, bucket elevator, or more frequently by a chain conveyor of the scraper or drag-link type. An installation of the latter type is shown in fig. 8, which is self-explanatory. The motor is housed in a small structure between the two tracks and the speed reduction gear is in this case mounted beneath the top terminal of the conveyor.

In Germany a small pneumatic plant has been introduced (see fig. 9) for clearing soot from the smokebox and flues. The electro-motor is shown on the extreme right, it is direct-coupled to a rotary exhauster; a partial vacuum is produced in the re ceiver which is located in the central position over a rail track, for the removal of the soot. A partly flexible tube which terminates in a nozzle, is led from the receiver to the locomotive. Between the receiver and the exhauster is a dust collector, partly filled with water, which prevents the entry of gritty substances. Unlike more elaborate pneumatic plant (q.v.), a receiver is not here provided with an "air trap," but is, instead, fitted with a sliding gate and