Gilding and Bronzing

gold, bronze, leaf, size and surface

After the size has been applied to the space to be gilded and has acquired the proper tack, the gold leaf is laid upon a calfskin leather cushion held in the left hand. The leaf is laid flat by means of the gilder's knife, and cut to the proper size, and is then deftly transferred by means of a brush, called the tip, to the sized sur face. This tip is kept slightly oily by being fre quently rubbed across the hair. The gilder is aided in this work by gently puffing the leaf with his breath. Where considerable surfaces are to be covered, many gilders take the leaf from the book by means of the tip, instead of first transferring it to the cushion.

Where "patent" gold leaf is used, the leaf is taken up on the tissue paper to which it is at tached, and carried to the sized surface by hand.

The gold, after being applied, is dabbed down; and, after it has been given sufficient time to ad here to the size, the loose gold leaf projecting beyond the sized edges is carefully dusted off, catching all the metal possible on a sheet of paper or something of the kind held below.

If a shiny surface is desired, the gold is bur nished after allowing the gold size a sufficient time to harden.

Gilding on glass is afterward "backed up" by a first coat of varnish or gold size japan, fol lowed by a second coat of black japan. In the best gilding on glass, a second layer of gold leaf is usually applied over the first, so as absolutely to cover any defects in the under layer.

Operation of Bronzing. In powder bronz ing, the surface to be bronzed is first painted, and is then coated with gold size japan; and when this has arrived at the proper tack, the bronze is applied by means of a ball of cotton or is gently blown on with a special form of bel lows similar to that used for insect powder. It

is then well polished with the cotton.

In bronze painting, the bronze powder is mixed with some suitable vehicle, which varies with the particular kind of bronze used. For aluminum bronze paint, so much used on orna mental ironwork, the so-called banana liquid is the best vehicle. As it is highly explosive, it should not be used in the presence of any open light. It is quick drying, retains its elasticity under severe exposure, and has no discoloring effect upon the bronze.

A good quality hard gum varnish, taking care to select one that will not diminish the luster of the bronze perceptibly, when thinned with tur pentine or benzine to good flowing consistency, makes a suitable vehicle for any kind of bronze.

Prepared bronze paints are sold ready mixed, or the liquid and powder are sold separately to be mixed as wanted. Most of these are very satisfactory, but the range of colors is limited.

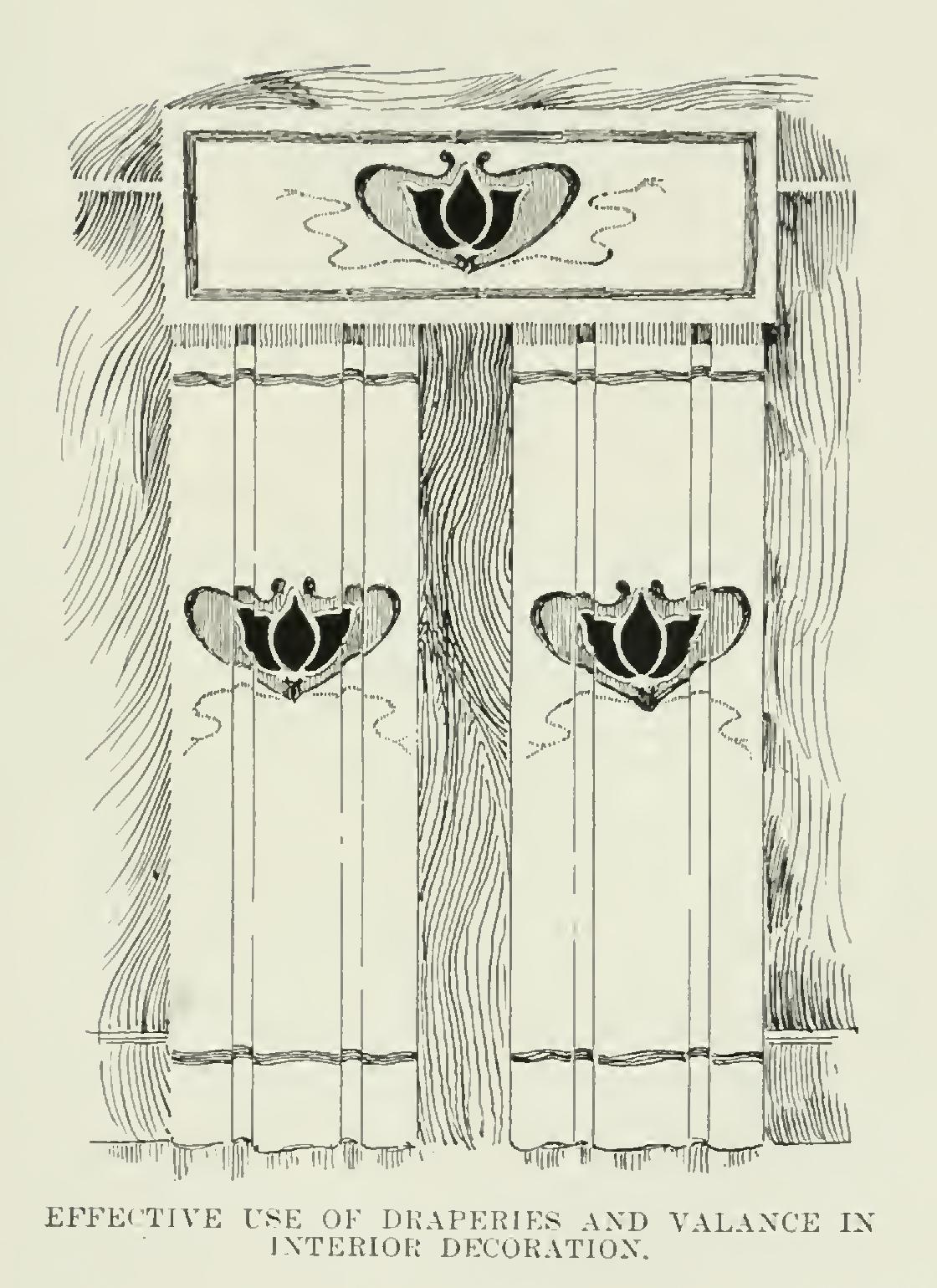

Bronze powders are made not only in the usual gold, copper, and aluminum colors, but also in a large range of other colors, including reds, blues, and greens, all having a brilliant metallic luster. To get their full effectiveness, these colored bronzes can be used only in the powdered form on a sized surface. They are particularly useful in ornamental stenciling, the design being stenciled with gold size japan or with a colored paint made to dry tacky.