A Bench

stock, shown, top, piece, lever and amateur

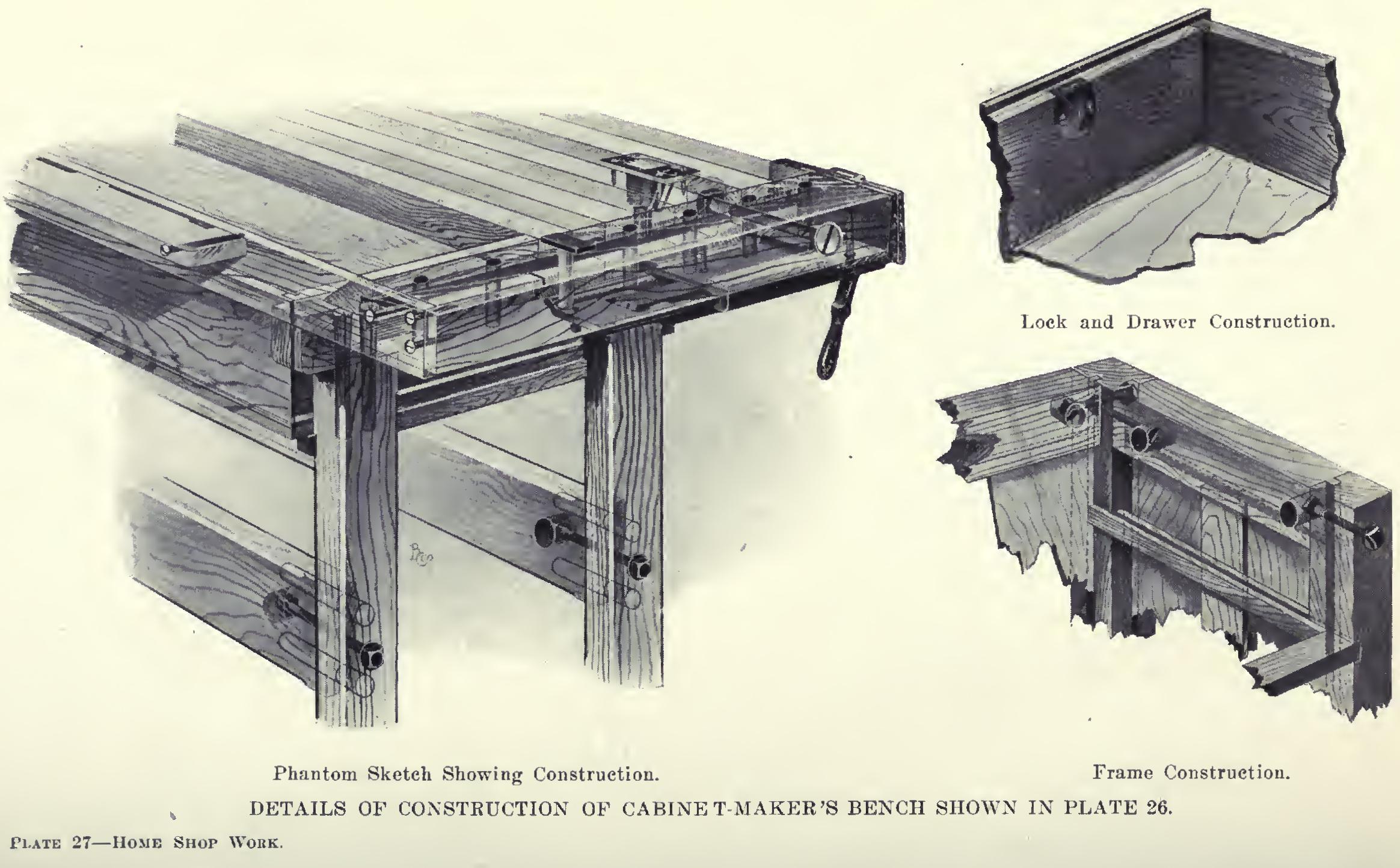

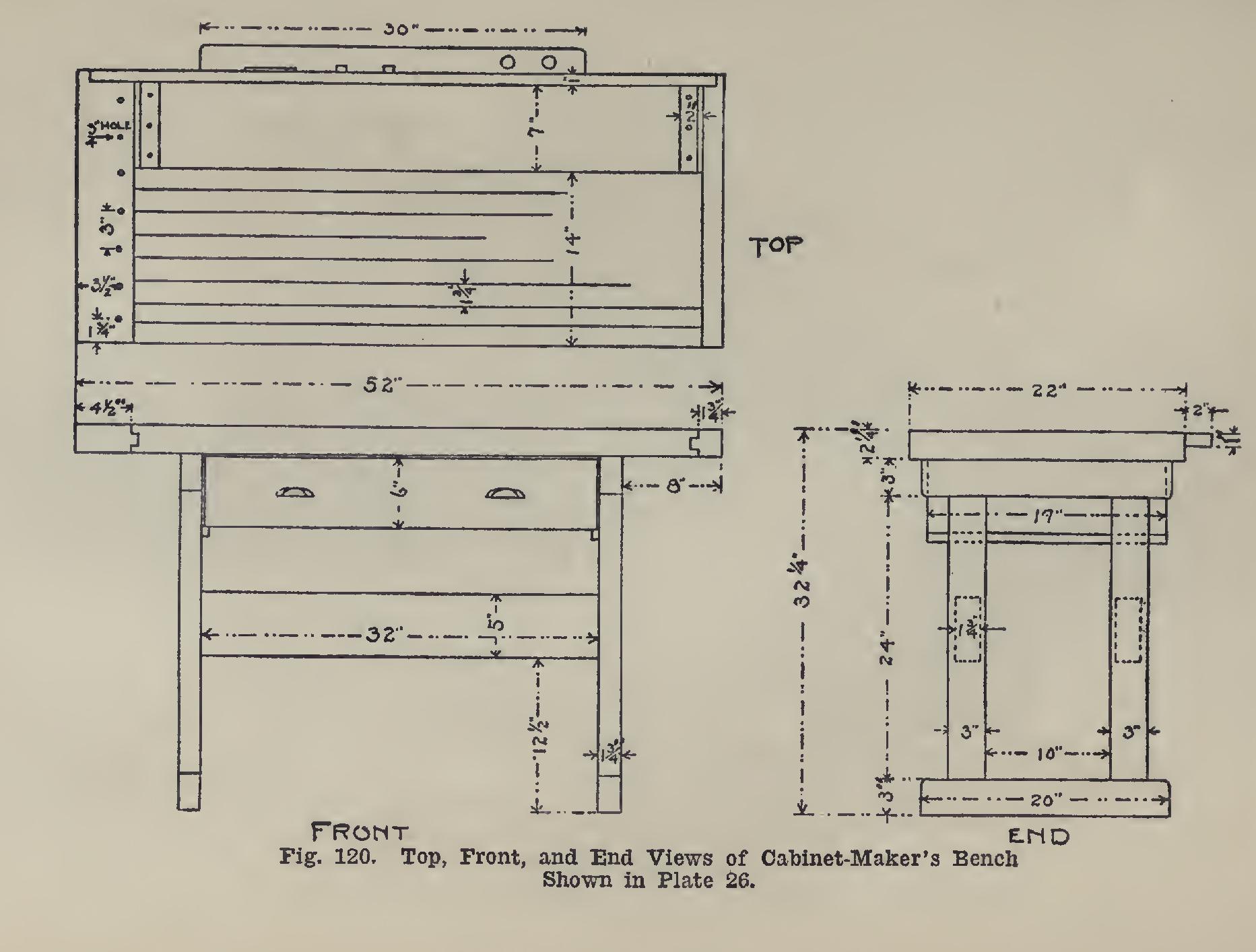

A BENCH The bench shown in Plate 26 and Fig. 120 is one the writer has used in his work for a number of years, and one which has proven quite satis factory.

Good benches are the result of years of study. There are many things going to make up a good bench, that the amateur bench-maker knows little about. In fact, in a good bench, practically every point in its construction has been argued for and against, and finally decided by the test of hard usage. The writer considers, therefore, that he is best answering the requests for a de scription of a good bench by presenting this one, which has had the best thought and study of its originator through a long period of develop ment.

Such a bench is especially suitable for the home workshop, for it is nicely finished and as trim and neat as a piece of furniture. The single drawer provides space for the small tools, while to the back is fastened a tool rack for the saws, chisels, and larger tools. The bench is ample in size for the needs of the amateur with work such as chairs, desks, etc.

This same top construction may be used, and a bench built with the base completely filled with drawer space, as is shown in Plate 28.

One who has ever used a rapid-acting vise will not need to be told the advantages of that style over the old-fashioned continuous-screw kind which our fathers used. To one who has never used one, we suggest that the time alone which is saved, not to mention the satisfaction in being able to get quick results, is well worth the small difference in cost. In the vise shown in the picture, throwing the lever a vertical position permits the movable jaw of the vise to be moved out or pushed in as far as is desired. To fasten a piece, throw the lever vertically, pull the jaw out sufficiently to permit the piece to be inserted, move the movable jaw up against the piece by pushing on the lever, then swing the lever to the right about a quarter-turn.

For a first-class woodworker's bench, nothing but the best hard maple should be used; and it must, by a11 means, be thoroughly seasoned. A

bench made of poorly seasoned maple is certain to prove a great disappointment. Order the stock mill-planed and sandpapered as indicated in the accompanying stock bill. Stock specified S-2-S, surfaced on two sides, has an allowance of inch for dressing. Stock specified S-4-S is of exact width and thickness. All stock is ordered inch extra length, to allow for squar ing the ends.

Mill Bill for Bench For the frame, sandpapered : Begin work upon the frame. Make the ends first, and glue them up. The phantom sketch (Plate 27) shows the top and bottom horizontals doweled to the verticals. The stock bill calls for enough extra length for these verticals to permit of their being tenoned entirely through the horizontals, then glued and wedged. There is a cross-strain put upon these joints that necessi tates them being made as strong as possible.

From the drawing it will be seen that the holes for the draw-bolts of the girts are in the middle of the verticals, so that the top and bot tom of the end frames are reversible.

Square up the girts, and bore for the dowels and draw-bolts. Use a 6-inch machine bolt. Chamfer the parts as shown in the picture. These parts may now be assembled.

Make the top next. This will prove the most difficult part of the whole project, because of the bolsters which are to be tongued and grooved to the ends of the bench-top proper.

The ordinary bench does not have these bolsters; and the amateur may, if he likes, make the top without them, making the top surface level for its full width.

Experience with both kinds of tops has shown the writer that the cross-clamping be tween vise-dog and bench-dog will, unless done by the experienced mechanic, open up the glue joints. With the bolster, such as is shown in the picture, this cannot happen, for the strain is along the length of the bolster and not across the glue joints.