A Hall Clock

inches, s-4-s, rails, screws, inch, s-2-s and lag

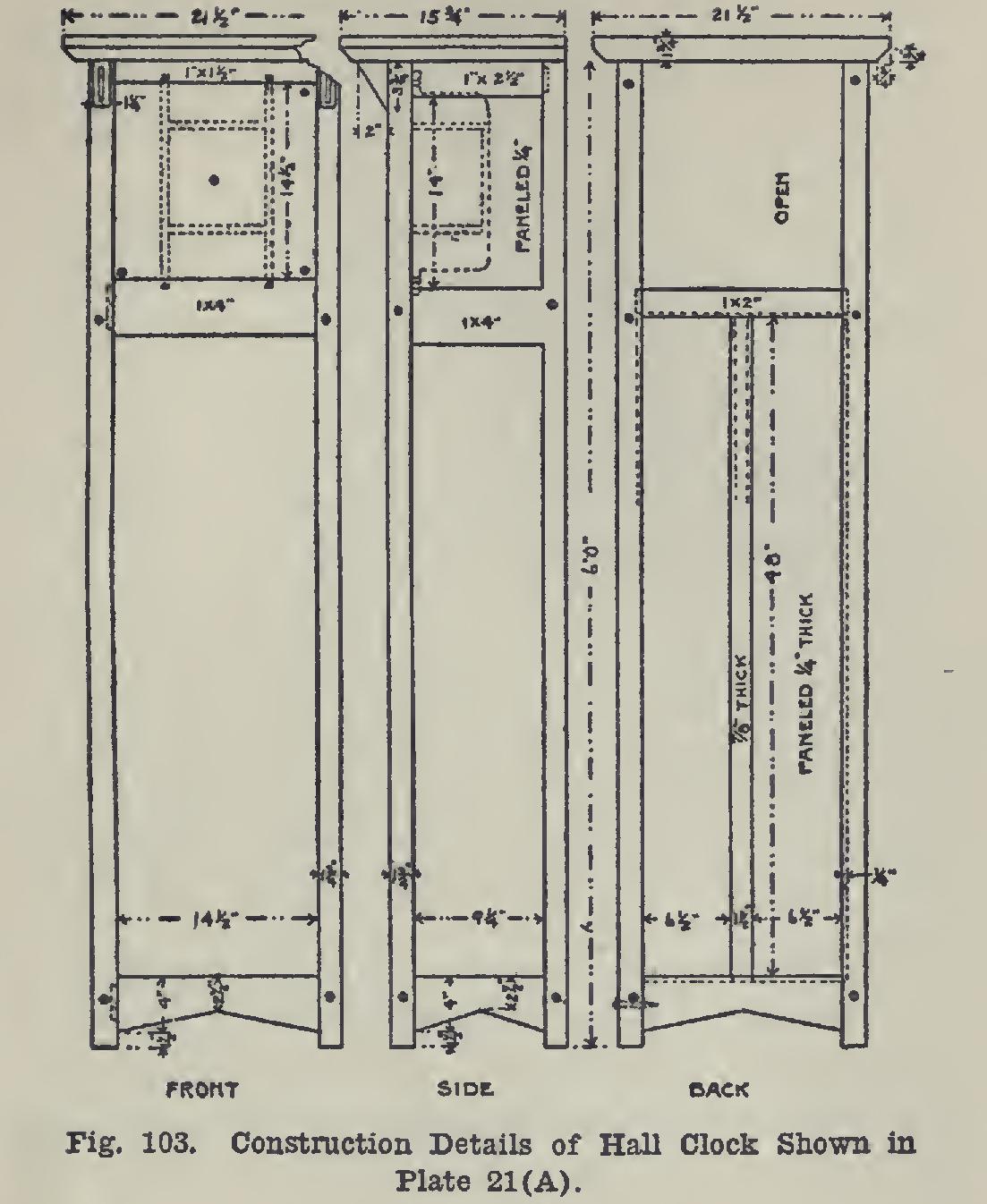

A HALL CLOCK For the hall clock illustrated in Plate 21 (A) and shown in working drawing in Fig. 103, there will be needed the following pieces. Order them mill-planed and sandpapered as indicated in the stock bill. "S-4-S" and "S-2-S" are abbrevi ations that will be understood at the mill as meaning surfaced or sized or smoothed on four and on two sides, respectively. Quarter-sawed white oak makes up nicely. It is carried in stock by most dealers, and takes a beautiful finish. Plain-sawed red oak is very appropriate for mission designs such as these: Mill Bill for Hall Clock 4 posts, by inches by 6 feet 1 inch. S-4-S.

3 rails, 1 by 4 by inches. S-4-S.

4 rails, 1 by 4 by 101/2 inches. S-4-S.

1 rail, 1 by 2 by inches. S-4-S.

1 rail, 1 by 11/2 by inches. S-4-S.

2 rails, 1 by by 101/2 inches. S-4-S.

1 stile, by by 48% inches. S-4-S.

2 panels, by 7 by 48% inches. S-4-S.

2 panels, by 9% by inches. S-4-S.

1 panel, by 14% by inches. S-4-S.

1 top, by 16 by 22 inches. S-2-S.

2 brackets, by by 4 inches. S-2-S.

Stock for the box which is to contain the movement should be made of yellow pop lar. The size and construction of the box will depend somewhat upon the kind of movement that is to be used. Ordinarily there will be needed: 2 pieces, by 6 by inches. S-2-S. 2 pieces, by 6 by 7 inches. S-2-S.

1 piece, by 8 by 8 inches. S-2-S.

Begin work by squaring the posts to length. Place them side by side, and lay off the mortises and the auger-holes for the lag screws. Chisel these mortises, and bore the holes. The tenons are to be stub tenons—about inch long—so that the mortises need not be cut much deeper than inch. These stub tenons hold the rails from turning, the lag screws giving the strength needed. A by lag screw is a good size to use. There will need to be a smaller hole in the end of the rail than is bored in the post inch is about right. It will be well to have a few of the screws inch longer than the others, to be used in case the shorter screws should strip the wood threads because of over-wrenching.

Lay off the tenons of the rails, and cut them. These rails are all 1 inch thick, and will stand shouldering on the four sides of each end.

Three-eighths or inch is a good thickness. The location of the holes in the ends of the ten ons can best be determined after the tenons are fitted into their mortises.

Plow the rails and posts for the panel grooves. Cut and fit the panels, and then as semble the whole, gluing the tenons before inserting the lag screws.

The top may now be squared up. It has a bevel on the front and ends. Fasten it in place, nailing down into the posts.

The two brackets are easiest got by squaring a piece to 2 by 3 and inches long, then ripping diagonally. Plane these surfaces smooth, and put on the ornamental groove as shown in the photograph. Fasten the braces with light brads, covering the heads with putty colored to match the finish.

The face or dial may be either of wood or of heavy copper. Whichever is used, there will be needed four corner-blocks fastened to the rails, into which screws through the face can be fastened.

Bronze figures for the dial have two prongs each, which are put through the face and clinched on the back.

The size and shape of the box for the "works" will have to be determined after they are purchased. In general there will need to be two verticals fastened top and bottom to the front rails of the frame, as indicated in the draw ing, with two horizontals, the lower so placed as to bring the pinion to the center of the dial, approximately. Hooks with nuts are furnished, that permit the fastening of the "movement" to the bottom horizontal. They are long enough to permit of a little "blocking up" if the pinion is too low. A back is needed to keep the dust out. Like the front, it should be fastened with screws so as to allow easy access to the movement.

The adjustment of a clock is rather delicate; and if the clock is out of level, the ratchet will not release properly, hence the clock will not run.

To permit of the adjusting of the clock frame to uneven floors, bore and insert four lag screws —large-headed ones—in the lower ends of the posts. The clock frame will rest on these, which may be turned at will so as to "take up" any unevenness in the floor.

As for the finish, a dark effect will be most appropriate for this design. A water stain, sanded lightly when dry, followed by a dark filler, colored to match the stain, and this, when dry, by several coats of wax, makes an easy and satisfactory finish.