Electric Light Pendant Fixture

wood, piece, inches, s-4-s, dark and square

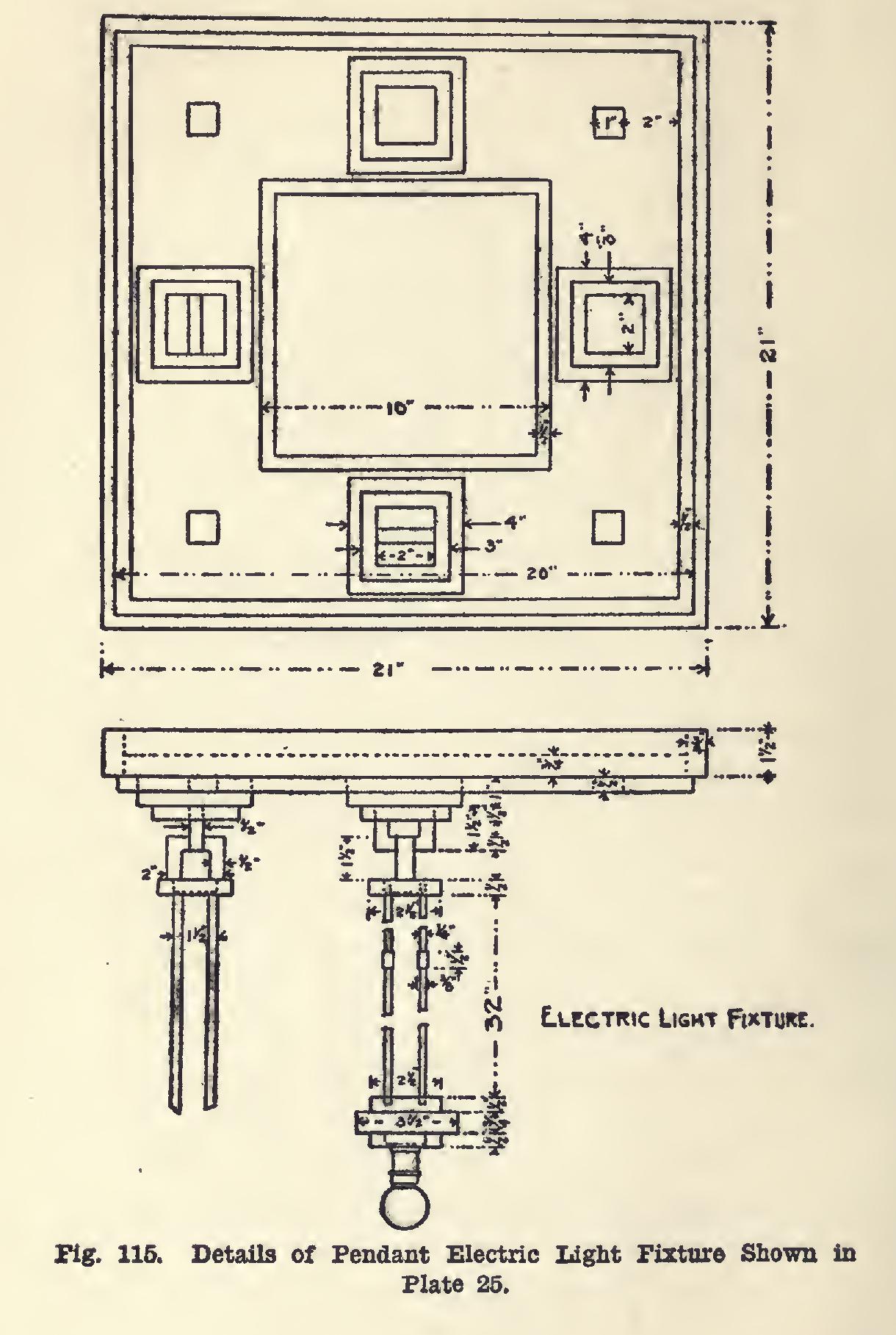

ELECTRIC LIGHT PENDANT FIXTURE With the extended introduction of the elec tric light, has come the demand for new lighting fixtures. Hardly a village now but has its electric light plant. In many places farmers are putting in their individual lighting plants. To meet the demand for a fixture which can be con structed in the home workshop, we offer the accompanying design (Plate 25 and Fig. 115). It can be constructed wholly of wood —two kinds being used, the parts showing light in the photograph being of some close grained, hard, light-colored wood, and the rest of a dark wood. If one has the neces sary tools for cutting and brazing brass, a very effective result is obtained by making the light parts of and inch square brass tubing. We have made out the mill bill for wood only.

Mill Bill for Electric Light Fixture 1 piece, dark wood, by 10 by 42 inches, S-2-S; 1 piece, dark wood, 1 by 4 by 18 inches, S-4-S ; 1 piece, dark wood, 1/2 by 1 by 5 inches, S-4-S ; 1 piece, dark wood, by by 86 inches, S-4-S ; 1 piece, light wood, by by 285 inches, S-4-S ; 1 piece, light wood, by by 528 inches, S-4-S; 1 piece, dark wood, 7/16 by by 7 inches, S-4-S ; 1 piece, light wood, by by 44 inches, S-4-S ; 1 piece, dark wood, by by 60 inches, S-4-S; 1 piece light wood, by by 8 inches, S-4-S.

In this bill, the thickness and widths are specified exact; but in the lengths, allowance of inch to each piece has been made for cutting. It will be seen that instead of specifying each piece, the lengths of pieces having like thickness and widths have been combined. This saves expense in that it does not require the mill men to cut to length, and is no disadvantage what ever. Order all the planed surfaces sandpapered at the mill. The machine will do it much more quickly and better—provided the sanders are careful not to "sand them out of square." Be gin by building the top. Miter the 10-inch board so as to make a square inches (Fig. 115). Around this, miter the by piece, keeping the edge flush with what is to become the lower side of the part just made. With the

by light wood, cover the joint thus made. Inside this, and of the same material, build another square 10 inches from outside to outside.

The little corner-blocks are to be 1 inch by 1 inch by inch thick, placed as shown in the drawing.

All these pieces are to be fastened with thin brads and glue. The heads will be set and cov ered later with putty which matches the finish of the wood. It will be necessary to drill holes lest the brads split the wood, especially on the mitered corners of the smaller pieces.

Next make and place the blocks to which the pendants are to be fastened. On these, build of by stock the squares of light wood, and we shall be ready to begin on the pendants.

The drawing, Fig. 115, shows the connection of pendants to their supports when metal tubing is used. For wood, the connections must be made so as to avoid rigidity, else the strain which might come on the connections through accidentally striking them a side blow, would be likely to break them. This loose connection is obtainable by making a link connection like that of a chain, one of the square links passing through the other.

The easiest way to construct the parts into which the four rods fasten their upper ends, is to square up a piece of the 7/16-inch stock to inches each way, and cut out the corners sufficiently to take in the rods at each. Around this, break the by light wood.

The part below will be made by letting the rods into the corners of pieces squared to by inches by 1 11/16 inches long, the grain extending vertically when the piece is placed. Around these, break the by light wood; and around this, the by l/2-inch light, wood.

The ornamentations in the middle of the rods may be made by "breaking" the rods and doweling them to pieces of by % by stock.

The photograph suggests the manner of wir ing, the wires passing up between the four rods to the top, thence through the top and to the central outlet.