Hammered Metal Work for the Home Shop

design, copper, fig, trays, piece, round-nosed and holder

HAMMERED METAL WORK FOR THE HOME SHOP As a supplement to the heavier woodworking designs, the home craftsman ought to give a little attention to light hammered metal work. Many interesting and useful pieces can be made of sheet brass and copper—pieces valuable in themselves, such as trays, sconces, candlestick holders, sun-dials, etc., and also metal adjuncts to wood pieces, such as umbrella stand trays, chest strappings, ornamental hinges, etc. Just a few words concerning this work may therefore be in order.

The necessary tools for light hammered metal work are few, and are such as can be found about the carpenter shop. There will be needed for this work a riveting hammer, file, metal shears, rivet punch, flat and round-nosed pliers, screwdriver, and sheet brass and copper of Number 23 gauge.

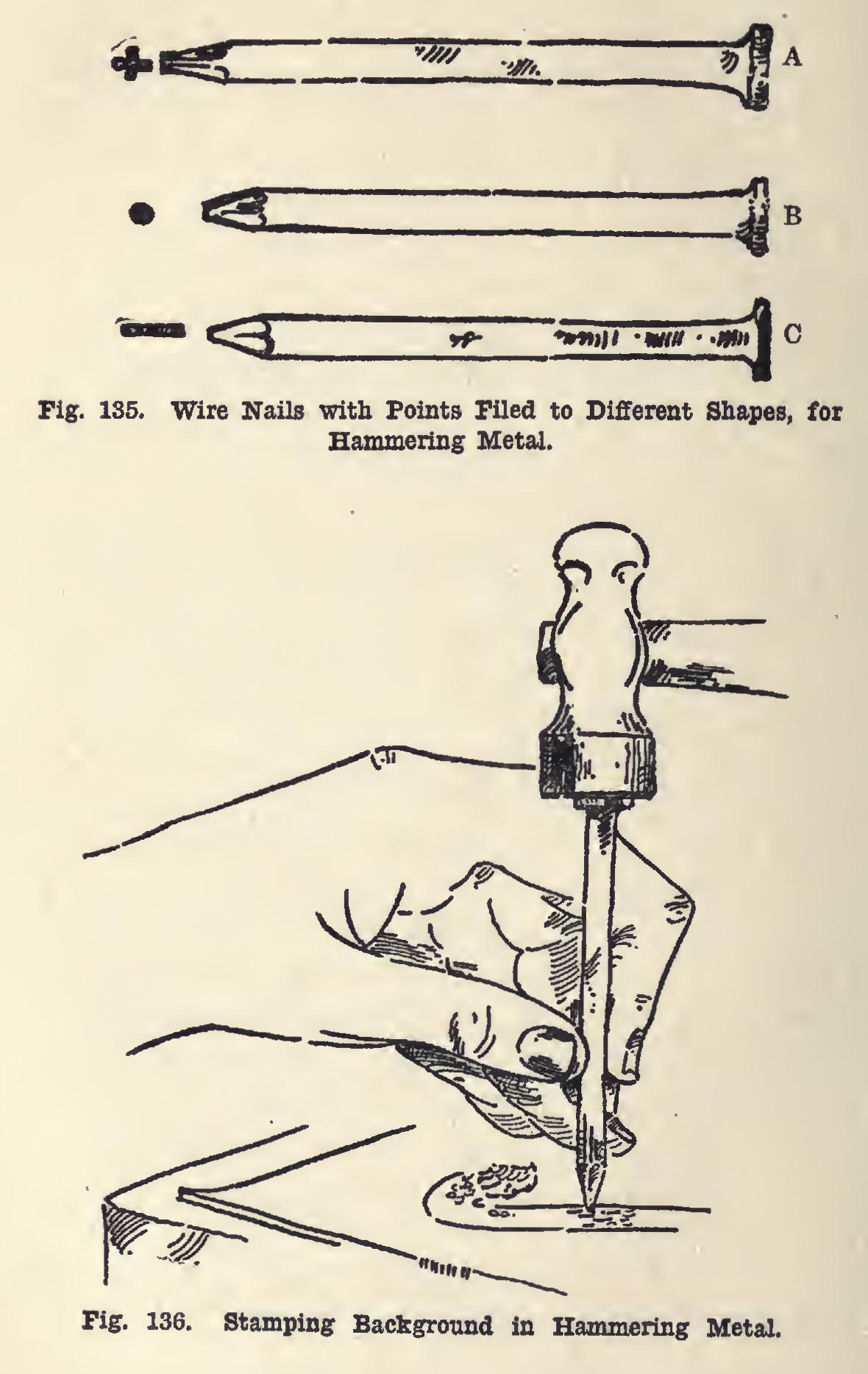

To make the copper trays, such as are shown in the accompanying illustration (Plates 29 and 30), proceed as follows: First, cut off a piece of copper so that it shall have one-half inch extra metal on each of the four sides. Second, with a piece of carbon paper, trace upon the copper lines that shall represent the margin of the tray proper, and the lines along which the upturned sides of the tray are to be bent; also trace the decorative design. Third, with a nail-set, make a series of holes in the extra margin, about three quarters of an inch apart, and large enough to take in a three-quarters-inch slim screw. Fourth, fasten the metal to a thick board by in serting screws in these holes. Fifth, with a twenty-penny wire nail that has had the sharp ness of its point filed off (Fig. 135, B) stamp the background promiscuously as in Fig. 136. By holding the nail about a quarter of an inch above the work, and striking it with the hammer, at the same time striving to keep it at a quarter of an inch above the metal, very rapid progress can be made. This stamping loWers the back ground, and at the same time raises the design. Sixth, chase or stamp along the border of the design and background, using a nail filed as in Fig. 135, C. This is to make a clean, sharp di vision between background and design. Sev

enth, when the stamping is completed, remove the screws and the metal from the board, and cut off the extra margin with the metal shears. File the edges until they are smooth to the touch. Eighth, with the flat pliers, "raise" one side of the tray, then the other side. Ninth, raise the ends, adjusting the corners as shown in the illustration. Use round-nosed pliers for this purpose.

Copper is frequently treated chemically to give it color. For these trays, however, the color which copper naturally assumes with age is quite effective.

In making symmetrical designs—designs in which two or more parts are alike, only one of the parts is drawn freehand. The others are ob tained from this one by folding the paper upon which the design is to be made, placing carbon paper between, and tracing the part of the design already drawn. This insures exact symmetry.

Figs. 137 and 138 illustrate the manner of beating up a copper bowl. In Fig. 137 the piece of copper is placed over a hollow in one end of a block, and is beaten with a round-nosed ham-. mer. The metal is given a circular motion as the pounding proceeds. Bowls may be orna mented by having borders made around the edge, a small metal-cutting saw being used to cut out the open parts of the design. These saws are manipulated quite like the wood coping or scroll saws.

A design for a sconce or candlestick-holder is shown in Fig. 139. It is to be made of No. 23 gauge brass, and the design is worked up quite like that just described for the trays. The drip cup is a piece of brass cut circular and shaped as indicated in Fig. 137. The holder may have four arms, as in Fig. 139, and is bent to shape by means of the round-nosed pliers. The form of the bracket which supports the drip-cup and holder is clearly indicated in Fig. 139.

Having pierced the bracket, drip-cup, and holder, these three parts are riveted as in Fig. 140. It will usually be found easier to rivet, if the holder is not shaped until after the riveting is done. The bracket is then riveted to the back of the sconce. Small copper rivets are used.