Choice of Concrete Mixtures

quantities, measuring, tables, cement, cubic, batch, weight, construction and gravel

Measuring Out Quantities for Mixing The problem of giving a table for measuring out exactly the proper quantities to be mixed together in making concrete, would be compara tively simple if a uniform standard were adopted for either the weight or the volume of the pack ages (barrels or bags) which are shipped by different manufacturers of cement. There is, however, no such thing as a standard barrel or a standard bag, both the weight and the size of these packages varying considerably with the different brands. A 1:2:4 mixture, using any one brand, will give a concrete differing some what from a mixture ostensibly the same in pro portions, but using another brand. Moreover, a barrel of packed Portland cement is considerably increased in volume when dumped loose; and here again there will be some slight variation among the different brands. A barrel, for ex ample, containing 3.5 to 3.8 cubic feet of packed cement will give a volume ranging somewhat over 4 cubic feet when dumped loose. It is therefore absolutely impossible to compile any working table indicating volumes and weights for mixtures which will be capable of universal application and which will at the same time insure an absolute uniformity of mixture irre spective of what brand of cement is used. For tunately, however, the character of Portland cement concrete is such as to allow considerable leeway in the matter of proportioning; and these small variations—unavoidable in general construction work—are not sufficient to affect seriously the quality or strength of the con crete. Moreover, it is always possible to be on the safe side.

Some authorities, for the sake of simplicity in proportioning and measuring, consider that 1 bag Portland cement=1 cubic foot=100 lbs., thus making 1 barrel=400 lbs. It is, however, a closer approach to actual facts as found in practice, to take the average weight of a barrel as 380 lbs., thus making the weight of a bag 95 lbs.

Throughout the present work, unless other wise expressly stated, all proportions will be given by volume, not by weight.

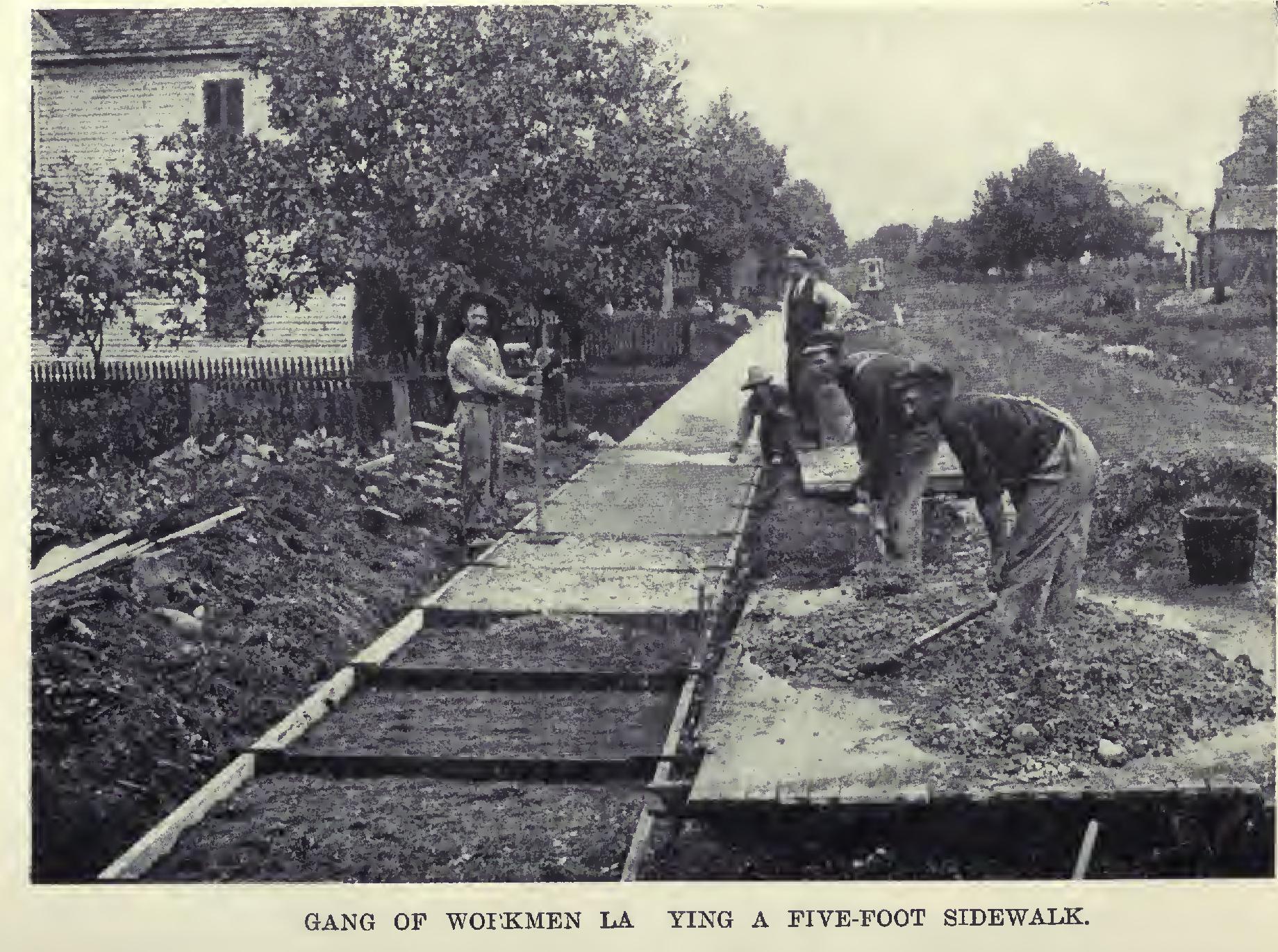

Very often, in plain concrete work, such as foundation or sidewalk construction, the mate rials are measured from wheelbarrows or buckets whose capacities have been accurately determined, or in some other simple and fairly reliable manner. The use of more uniform and accurate methods of measuring, however, is recommended; and in all cases, measurements should at least be checked up—especially when there is any change in the quantity desired, as, for example, in batches requiring less than full wheelbarrow loads.

A convenient form of measuring box can be made from any kind of rough boards. It may be rectangular in shape with perpendicular sides, and should be provided with a short handle at each corner (see Plate 3). It should have no top or bottom, being filled only at the place of mixing, and emptied by being simply lifted up. It should be of three or four cubic

feet capacity, and may be graduated so that one, two, or more cubic feet can be accurately measured.

In measuring, do not pack or ram the mate rial. Sand, gravel, and stone should be meas ured loose. Simply shovel in the loose material, strike off level across the top, and lift the box away.

Tables for Measuring Materials The importance of the tables which engi neers have compiled for the convenience of practical workers in all lines of construction, cannot be too strongly insisted upon. They are the richest fruitage of practical experience, being based on a great multitude of notes, meas urements, and observations made in connection with actual examples of construction, and are veritable treasure-stores of practical, labor saving information. It is not necessary for the ordinary worker in concrete, or steel, or any other form of material, to attempt the imprac ticable task of exploring all the highways and byways where the testing engineer finds him self at home. Tables are available which will cover every phase of every construction prob lem likely to be met with in ordinary practice; and a little familiarity with the use of these tables will enable anyone to take advantage of the immense labors of others, and to bring to bear on any problem confronting him the results of the widest experience and the highest skill.

In measuring out the quantities required for mixing concrete, it may be necessary to pro ceed in different ways. We may, for example, have to mix in small batches, and shall need to know how much sand and gravel to lay out for two or three bags of cement at a time; or we may have to decide on the quantities as required per cubic yard of the space to be filled with concrete; etc.

Several tables will therefore be given, meet ing these different conditions; and by reference to these tables the quantities required for any ordinary mixture can be determined almost at a glance.

Quantities for Batch Mixing. Tables XI and XII, compiled by Percy H. Wilson and Clifford W. Gaylord, show the quantities for a 2-bag batch. A 3-bag batch will require half as much more of each ingredient; a 4-bag batch, just double the amount; and so on. If the aggre gates used are sand and crushed stone or gravel, use Table XI; if natural-bank sand and gravel already mixed, use Table XII.

From these tables the quantities required for batches of any size can easily be calculated in the manner above described. They will simply be increased or diminished in proportion with the cement. Thus the quantities indicated by the tables—which are for 2-bag batches— would have to be doubled for a 4-bag batch; trebled for a 6-bag batch; etc.