Concrete Aggregates

sand, cement, coarse, fine, gravel, density and strength

The volume of concrete will not be equal to the combined volumes of the cement and aggre gates, but will be considerably less, because the finer particles hide themselves, as it were, in the spaces within the mass of the coarser particles. In this way, the pile of concrete resulting from a mixture of cement, sand, and gravel will be only slightly larger than the original pile of gravel. Six barrels of gravel, three of sand, and one of cement, for example, will not give ten (1+3+6) barrels of concrete, but will give only a little more than six barrels.

The volume or yield of the concrete affords, in fact, one method of determining the best pro portions of aggregates. If the proportion of cement is kept the same, that mixture of coarse and fine aggregates will be the best which will give the smallest volume of concrete from a cer tain weight of aggregate. This test is called the yield or volumetric test, and gives a rough but very quick and convenient indication of the rela tive density and strength of the concrete result ing from different mixtures of aggregates. The smaller the volume, the greater density and strength, and the better the quality of the con crete.

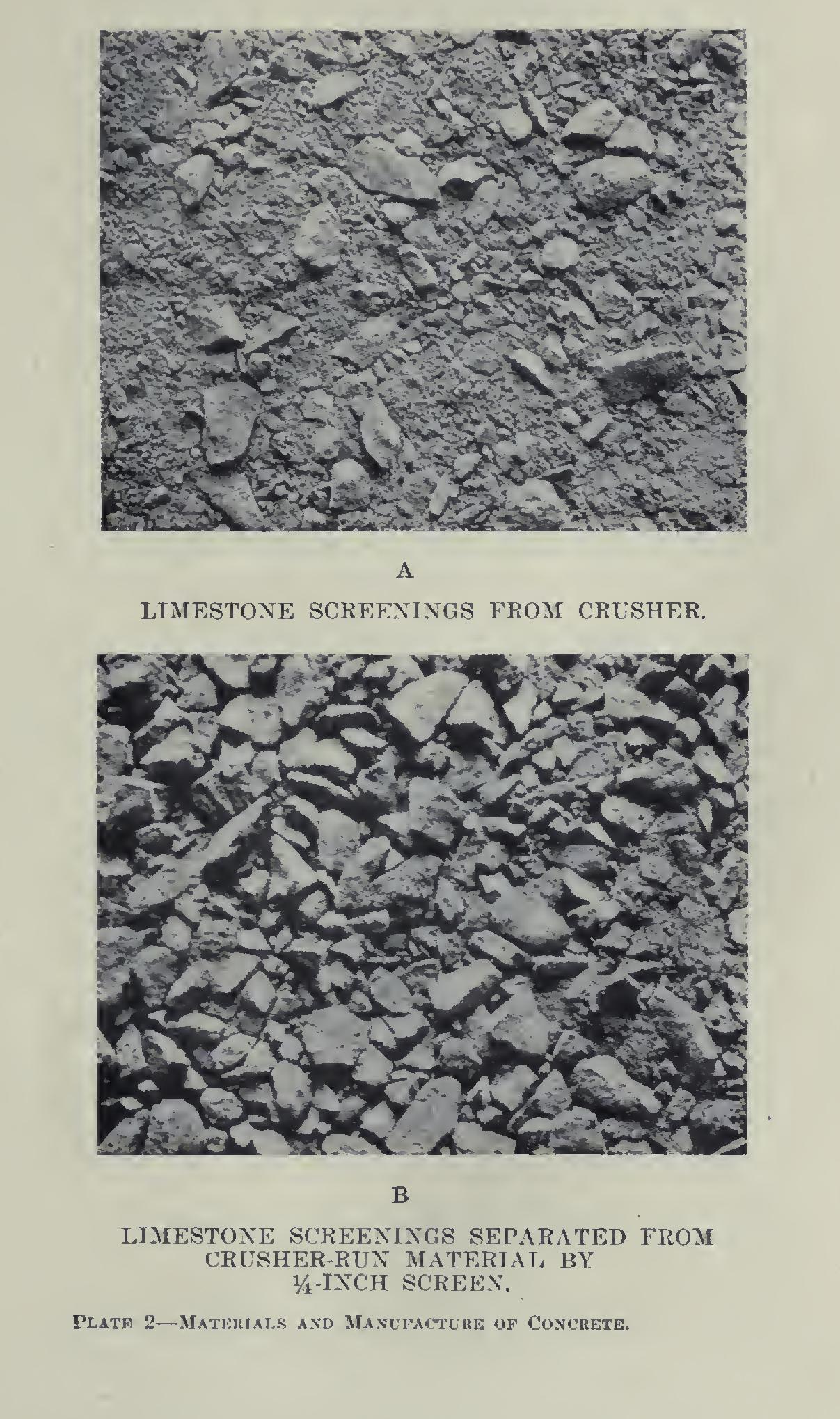

There is the closest relation between the density and the strength of concrete. Even a slight increase in weight per cubic foot will add very decidedly to the strength. In this connec tion the importance of the coarser aggregates cannot be too strongly insisted upon. The use of coarse material is essential to density, since coarse material contains the smallest amount of voids. Different kinds of sand, gravel, and stone vary greatly in the extent of their voids; and by judiciously mixing coarse and fine materials, the voids may be much reduced, and the weight and density of the concrete increased. The follow ing figures illustrate how voids may be reduced and weight increased by mixing fine and coarse materials: Pebbles, about 1 inch Sand, 30 to 40 mesh Pebbles mixed with sand, the sand being 38.7 per cent of the volume of the pebbles, or just enough to the voids.

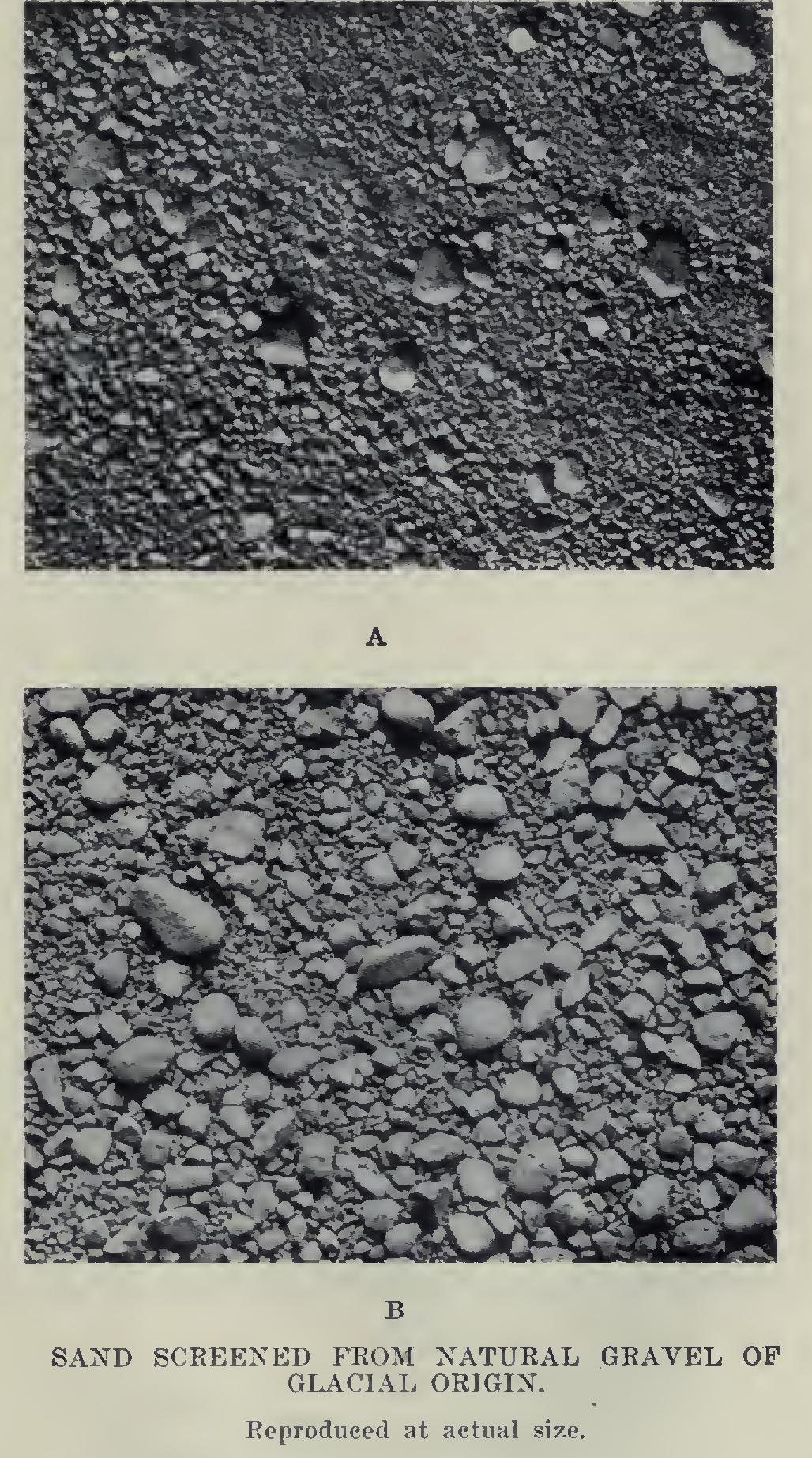

If sand be screened so as to take out the coarse grains, the voids will be increased and the weight reduced, thus injuring the sand for making concrete. Strength may be improved by adding coarse material, even though the pro portion of cement is thereby reduced. This has

been repeatedly shown by experiment. A mix ture of cement and sand alone will form a rather weak concrete, especially if the sand is fine. By adding gravel—say about twice the quantity of gravel that there is of sand, or a little more—a concrete will be obtained containing, of course, a greatly reduced percentage of cement, but of greatly increased strength.

In selecting aggregates for concrete, then, it may be laid down as a general rule that those should be chosen which give the greatest density. If it is practicable to mix two materials, as sand and gravel, the proportion which gives the great est density should be determined by experiment, and rigidly adhered to, whatever may be the proportion of cement it is decided to use. Well proportioned dry sand and gravel, or sand and broken stone, well shaken down, should weigh at least 125 lbs. per cubic foot. Limestone screenings, owing to minute pores in the stone itself, are somewhat lighter, though they may give equally strong concrete. They should weigh at least 120 lbs. per cubic foot. If the weight is less, there is probably too much fine dust in the mixture.

Selection of Sand.

For a rich mortar—that is, one relatively rich in cement—a coarse sand is best. For a lean mortar, a small admixture of fine sand with the coarse is beneficial. If very fine sand is the only kind available, the mixture must be excessively rich in cement, and a smaller quantity of the sand in proportion to the gravel or stone may be used. To secure great density and practical water-tightness of concrete, a larger percentage of fine grains is needed than is theoretically necessary for maximum strength. If a good, coarse sand is not available, almost any size of sand may be employed, provided a sufficient proportion of cement is used; though in this case, tests should be made to see that the mortar or concrete sets and hardens properly. There is one exception, however, to this rule— namely, in the case of concrete to be laid in sea water, where fine sand must never be used.

To choose between two sands, make each into a mortar with cement in the required propor tions; and the sand producing a smooth mortar having the smallest volume will give the greatest strength.