Dients

concrete, cement, sand, proportions, volume and aggregates

DIENTS The importance of a careful grading of coarse and fine ingredients has already been empha sized, and the general principles laid down which should govern the selection of aggregates for any proposed work.

It is equally essential, for the sake of econ omy and efficiency, that the concrete worker shall understand how to determine exactly the relative proportions of cement, sand, and coarser aggregates which must be used to obtain the densest and strongest concrete.

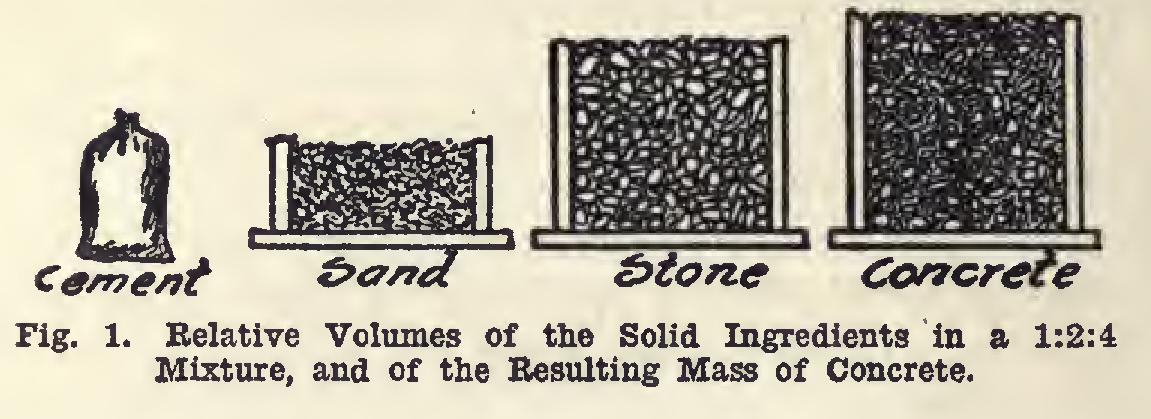

At the outset, it should be noted that in prac tical construction work, proportions are always indicated by measured volume, not by weight. In laboratory tests, where extreme accuracy of graduation and measurement is necessary, and also in the exact proportioning that is needed in the manufacture of Portland cement to secure absolute uniformity in the product, the moasur ing of ingredients is done by weighing them; but in the work of ordinary concrete construction, measuring by volume is much the easier and more convenient method, and gives an accuracy sufficient for all practical purposes. Thus a con crete designated 1:2:4 does not mean one con taining 1 lb. cement to 2 lbs. sand to 4 lbs. of coarser aggregate; but it means a mixture con sisting of 1 part or measured volume of cement, twice as much sand, and four times as much of the coarser aggregate (stone or gravel), making the whole mixture contain seven parts, though, when mixed together, these seven parts will not occupy seven times the volume of one part, but only a little more than the volume of the four parts. Fig. 1 illustrates graphically the rela tive volumes of the ingredients in a 1:2:4 mix ture, and of the resulting mass of concrete.

In general practice, there is wide variation in regard to the actual proportions used in the mix ing of. concrete. In many cases these proportions are decided upon in so crude a manner, and the measuring is also done so roughly and careless ly, that material is wasted, the cost of work un necessarily increased, and the results indifferent or unreliable.

The only way to determine the exact propor tions of cement and aggregates required for per fect concrete, is to make an experimental test in each case. Fortunately this is a comparatively easy thing to do; and, for the practical concrete worker, it will ordinarily consist merely in de termining the percentage of voids contained in the sand and other aggregates—that is, the pro portion of space that has to be filled with fine material.

As a result of the number of such special tests which have been made by engineers, and the careful investigations that have been carried out in connection with actual examples of con struction, an immense fund of valuable practical information has been accumulated, covering every detail of concrete work. This information has been embodied in the form of working rules and labor-saving tables which render it immedi ately available for practical application. By merely referring to these tables and observing these rules, the concrete worker can determine with a degree of accuracy sufficient for all prac tical purposes the proportions of cement and aggregates to be used in any kind of concrete work, and can be sure that he is adopting the proper methods of procedure.

No table, however, can be compiled, from which at least some slight variation is not allow able. This is because voids and weights of even the same kinds of aggregates vary so greatly, and the quantities of cement in original pack ages shipped by different manufacturers also differ considerably. The working tables, never theless, will indicate approximately the ideal proportions to use.

Determination of Voids Since the object, in mixing materials of dif ferent sizes in concrete, is to fill all the spaces, it follows that the voids in the coarse aggregate will indicate the amount of sand to use, and the voids in the sand will indicate, though but roughly, the amount of cement to use.