Hoists Engines

bucket, concrete, shown, hoist, drum, elevator and plate

ENGINES, HOISTS, AND ELEVATORS All the common types of power driving— steam, gasoline, electricity—are adaptable to the operation of concreting machinery. In the ma jority of cases, however, steam engines or gaso line engines are employed as the sources of mov rig. 21. "Eureka" Single Friction Drum Hoist.

ing power. As the detailed description of these adjuncts in building operations be longs to the field of Mechanical rather than Con structional Engineering, we shall here merely illustrate a few typical examples of installa tions such as are found in large concreting op erations.

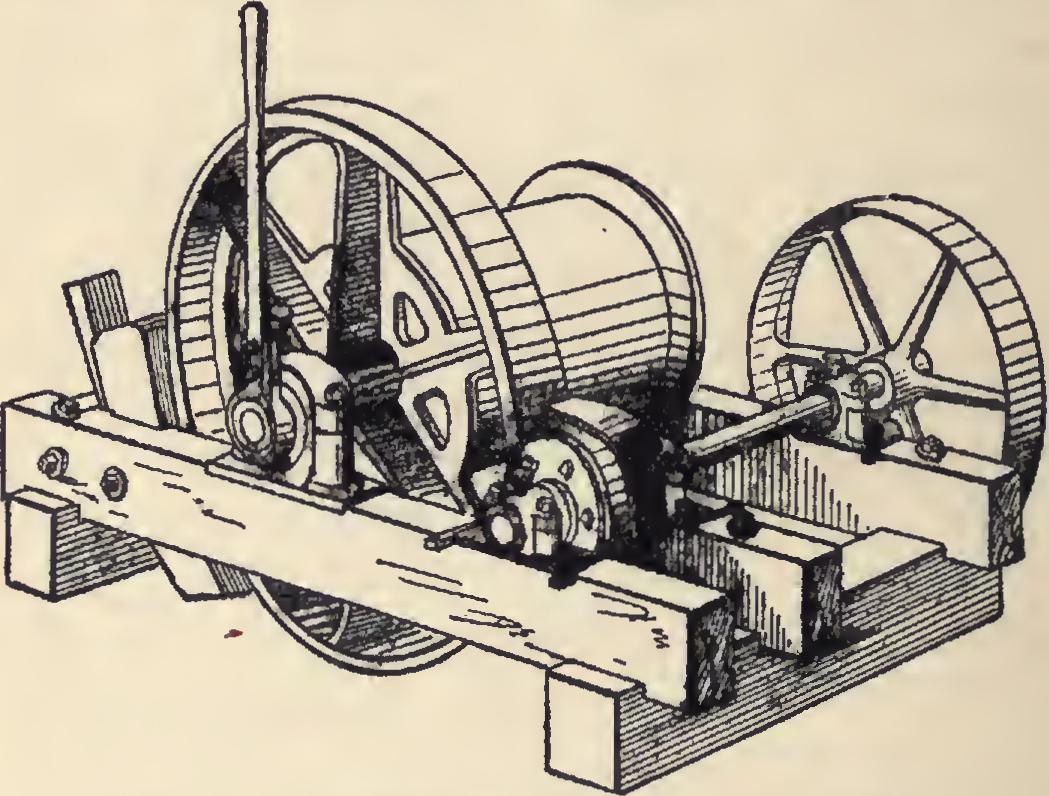

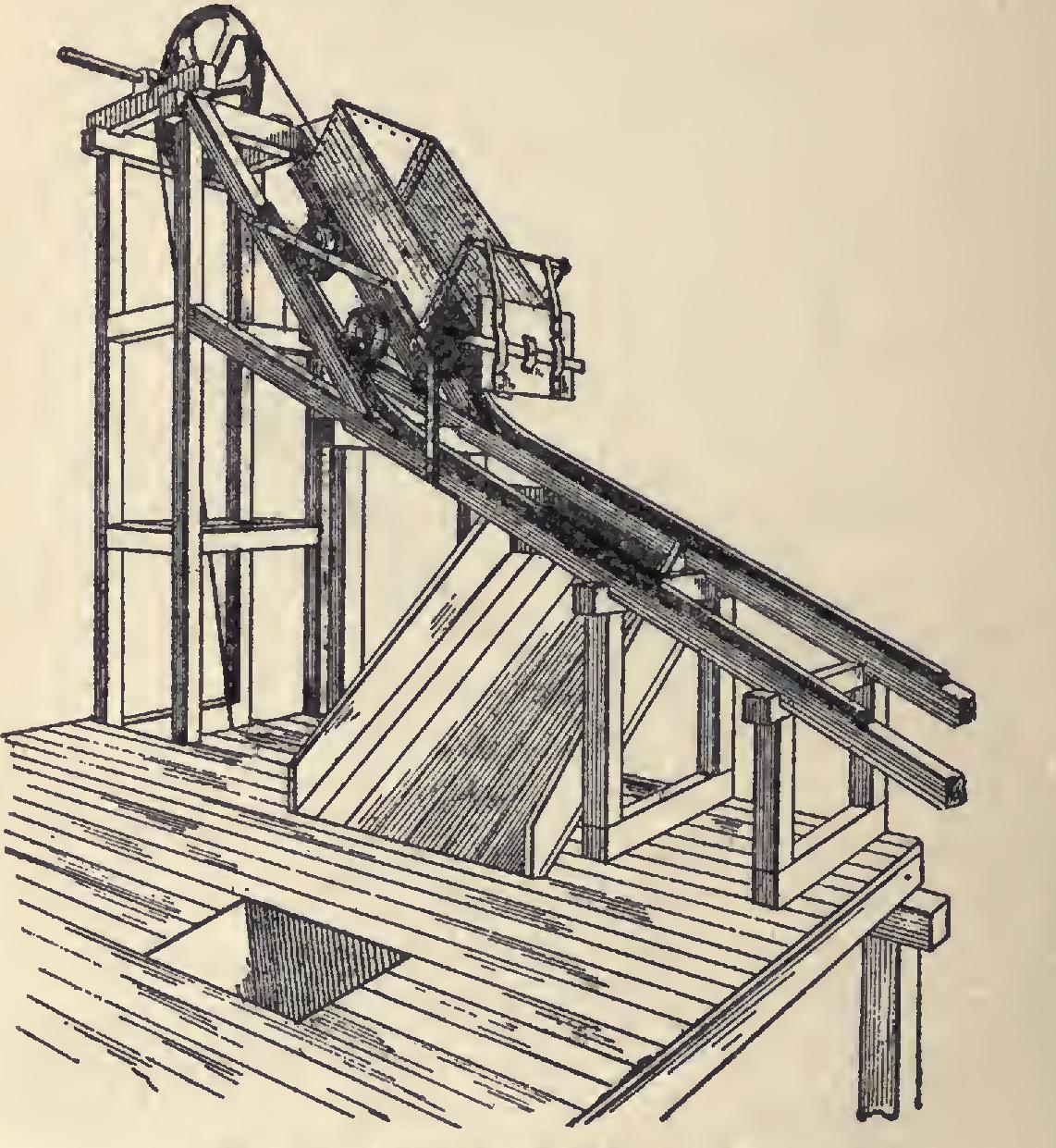

In Plate 13 (at the left) is shown a contract or's steam engine ("Hough" type) equipped with boiler and fittings complete, ratchets and pawls, double winches, foot-brakes, etc., adapted for hoisting material, elevator running, and other building operations, pile-driving, bridge and dock construction, quarry work, etc. In the same plate (at the right) is shown a "Koehring" Engine and Hoist Drum; and in Fig. 21, a "Eu reka" Single Friction Drum Hoist. In some cases, hoists are adapted to double platform ele vator work in which one platform is descending as the other ascends, in addition to having a drum for direct hoist work run independently of the cable sheave that operates the elevator platform. With such machines, material can be raised or lowered independently of the ele vator—an important feature in some circum stances.

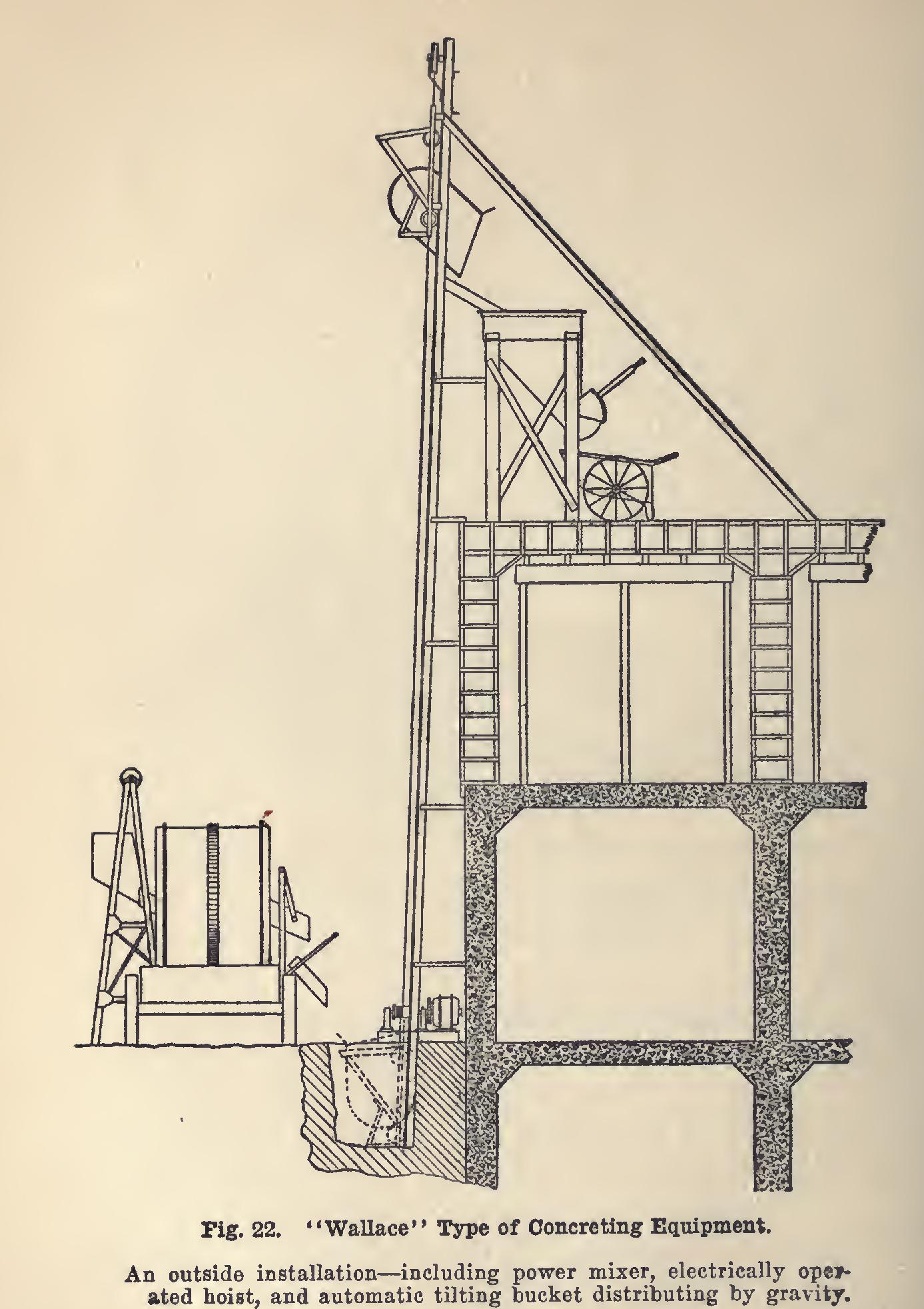

Fig. 22 is a diagram illustrating a complete "Wallace" Concreting Equipment operating outside the structure; other installations of this same type are adapted to inside work. The in stallation shown in the figure includes a power mixer with elevator for automatically hoisting and dumping the charging bucket; also an elec trically operated extension hoist, with automatic tilting skip or bucket discharging by gravity on the different floors as the structure rises. The concrete is discharged into a bin having a gate operated by hand-lever as shown, whereby the supply to the carts or wheelbarrows is con trolled. The skip automatically rights itself on its return.

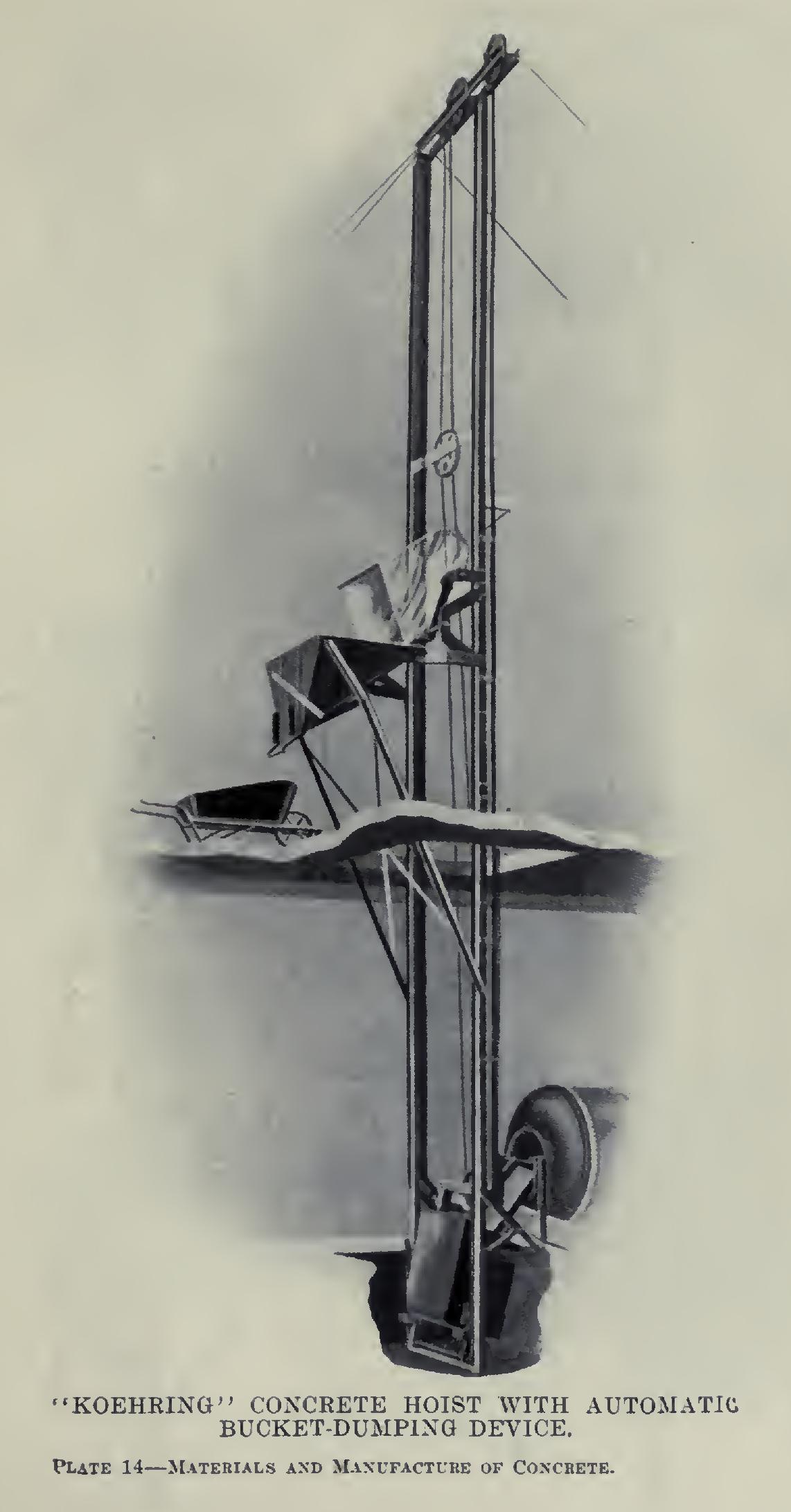

Installations engaged in interior work in similar operations are shown in Plates 14 and 15. In the "Koehring" plant (Plate 14), the bucket is hoisted by means of a cable from an ordinary hoisting drum. The bail of the bucket has roller guides, which guide the bucket up an I-beam track. When the bucket has reached the

point where it is desired to deliver the concrete, the rollers on the upper framework engage the angle-iron guide on the bucket, and the same tilts automatically. While thus tilting, the concrete is discharged into the bin, which is provided with a gate for filling wheelbarrows or carts. When the bucket descends, it rights itself automatic ally; and when it has reached the bottom of the track, where the mixer is stationed, it reclines under the discharge spout of the mixer.

The track, it is claimed, is self-supporting, and can be erected by merely guying it with ropes or guy wires. It can also be erected along the side of the building without additional framework, or in a wood frame tower.

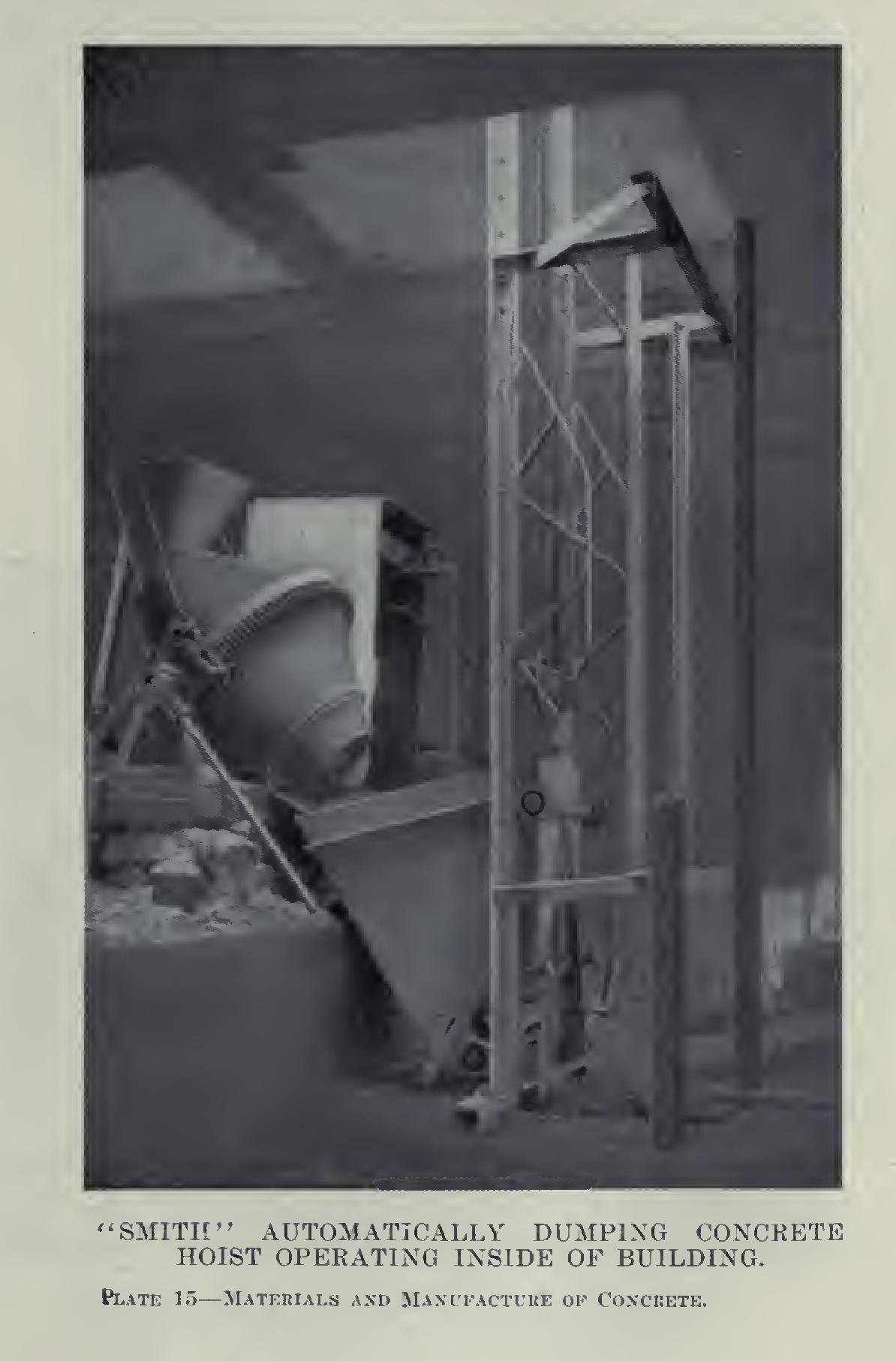

A similar cycle of operations is automatic ally performed by the "Smith" equipment illus trated in Plate 15. In this case the elevator frame must either be fastened to the structure or encased in a supporting frame, which may be built of scrap lumber or other cheap material; also, it is sometimes necessary to guy the top Action of the frame into place.

The mechanical aids employed in the han dling and depositing of wet concrete, the con veyance of concrete products (such as blocks) to and from curing and storage rooms, etc., in clude a large number of special devices intended • Fig. 23. Automatic End-Dump Car.

to lighten labor, promote efficiency, and lower cost—such as special types of light steel wheel barrows and hand carts, self-dumping steel buckets, cars, and wagons; sectional rack cars, for blocks; etc. Some buckets discharge auto matically by tilting; others, by "bottom dump ing;" while some of the latter are so constructed that their discharge may be controlled, the doors being opened or closed under load, so that con crete can be discharged directly from the buckets into forms. Some cars have an "end dump," as in the example illustrated in Fig. 23; others, a "two-way rocker dump," discharging by tilt ing to either side; while still others have the car body mounted on a sort of turnstile on the truck, swinging around and dumping at any point in a complete circle—an "all-round dump." Special cars for handling concrete blocks, sills, and other moulded shapes are built of channel or angle steel, with removable decks so that the load may comprise one, two, three, or more tiers.