Methods of Waterproofing

cement, compound, sand, concrete, water, claimed, pounds, coating and cent

In substructural work, walls exposed to ground water pressure are plastered on the inside with a waterproofed coating of mortar. This should be carried down below the level of the floor line; and when the floor is laid, it should also have a waterproofed top finish.

Hydrolithic Cement. Unlike the water proofing compounds intended for mixing with cement or concrete, hydrolithic cement is itself a waterproofed cement having, it is claimed, all the good points of a first-class Portland cement, with the addition that it is water-repellant and can be mixed with water only after the addition of sand and by special manipulation. Hydro lithic cement coating is a mixture of this cement with a special grade of sand absolutely free from loam and nicely graduated as to size of grain, from fine to coarse. It requires expert handling in mixing, and can be successfully used only after intelligent preparation of the surface to which it is to be applied. For these reasons hydrolithic cement is not offered directly for sale, but is applied exclusively by the propri etary company.

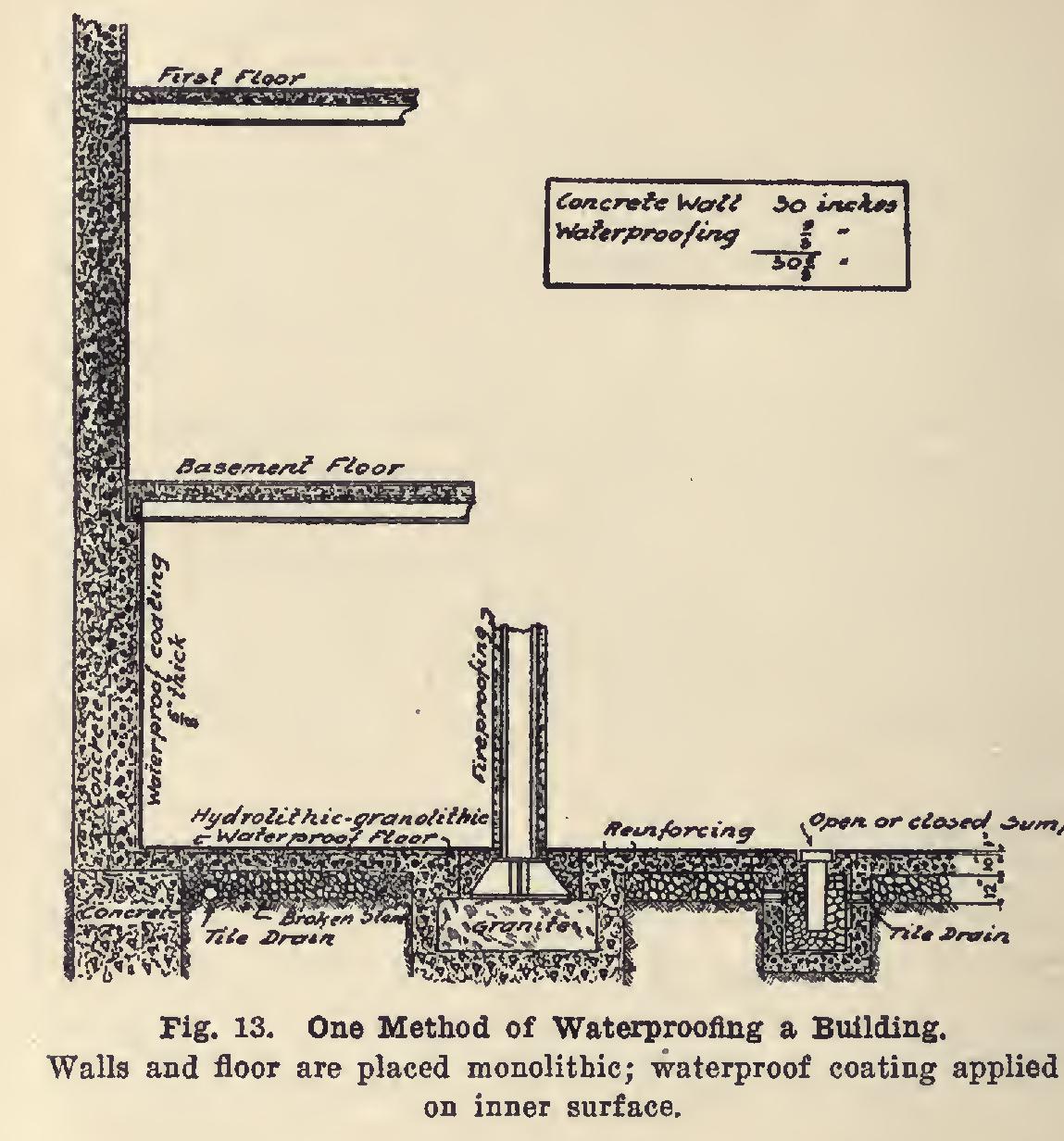

A typical example of the application of hydrolithic cement to the waterproofing of floors and walls is illustrated in Fig. 13. The process is claimed to meet successfully the severest con ditions of pressure in basements, subways, reser voirs, etc., and it is applicable to structures of stone or brick as well as of concrete. So intimate a bond is said to be secured by intelligent work manship, that the cement coating becomes an integral part of the structure to which it is ap plied. It has been known to withstand, without cracking and without showing the slightest evi dence of percolation, a pressure of 140 pounds to the square inch.

In waterproofing walls, the coating, where practicable, is placed upon the inner face of the wall, being applied in two coats—scratch and finish—and, when completed, is five-eighths of an inch in thickness, left with an even, smooth surface.

In floor work, the coating is placed over the upper surface of the floor-slab, where it fulfills the double purpose of a waterproof medium and a wearing surface.

Hydrolithic cement has little elasticity, and for that reason, especially in concrete construc tion, it is necessary to use proper reinforcement to provide against the development of shrinkage cracks which would cause leakage and other troubles.

Ideal Water-Proofing Filler.

This is mixed in small proportions with dry Portland cement before the addition of sand and water, and is claimed to render mortar or concrete made from the cement practically impervious to water, without affecting the color, strength, setting, or hardening qualities of the mixture. For most purposes, from one to two per cent of the weight of cement used is prescribed as sufficient. Thisis equivalent to from four to eight pounds of the filler to one barrel of cement, or from one to two pounds of filler to one bag of cement. The precise amount to be used must be left to the experience of the user, and depends upon the proportion of sand, etc., employed, and on the kind of work to be done. Where the conditions are severe, as in cistern and reservoir linings, larger proportions of filler should be used. Thorough mixing is of the utmost importance here, as in all cases where waterproofing com pounds are used. The proprietors claim that one per cent of the filler is sufficient to make concrete building blocks practically water-tight, and that it needs to be applied only to the rich facing of the blocks.

Medusa Water-Proof Compound. This is still another of the patented waterproofing materials placed on the market in powder form. Under ordinary circumstances, from one to two per cent of the weight of the cement used, or from four to eight pounds of the compound to one barrel of cement, is claimed to be sufficient for waterproofing purposes, though, where high pressures are encountered, as in cistern and reservoir linings, somewhat larger amounts must be used. The compound, it is further claimed, prevents the white efflorescence which so often renders cement work unsightly; and its use will also prevent crazing or formation of hair cracks on the surface of the concrete.

The method of using it is to mix it thor oughly with the dry cement before the addition of sand and water. It greatly increases the void-filling capacity of the cement paste, re ducing porosity even in comparatively poor mixtures strong enough in themselves for the purpose in view, but objectionable because of their degree of absorption. It is therefore claimed to reduce the proportion of cement needed to give water-tightness, and accordingly to be economical. The proprietors claim to have found by experiment that cement with one per cent of the compound, mixed with five parts of sand, gives a more impervious mortar than ordi nary untreated cement with two parts of sand; also, that hollow concrete blocks made with cement to which one per cent of the compound has been added, with five parts of sand and gravel, resist water better than blocks made in the proportion of 1 to 2 without the compound. It is also claimed that the compound contains nothing which can have any injurious effect upon steel or other metal, but, on the other hand, pos sesses properties tending to prevent corrosion of the metal embedded in the concrete in which the compound is used.