Screens and Separators

screen, material, cloth, conveyor, meshes, separator and finer

SCREENS AND SEPARATORS Under this head we find a considerable num ber of devices employed for separating and grad ing the coarser and finer particles in natural sand and gravel and in crusher-run material.

The simplest form of screen, commonly used in small operations, consists merely of a large, oblong sieve which is placed on end at an incline, and against which the material to be screened is thrown in successive shovelfuls by the workmen.

The finer ingredients, passing through the meshes, drop to the ground or platform, and accumulate in a heap behind or underneath the screen.

In larger operations, and particularly in those cases—as in some of the processes of Portland cement manufacturing—where the utmost accu racy in the grading of materials is necessary, hand screening is wholly inadequate, and re course is had to mechanically operated screening devices.

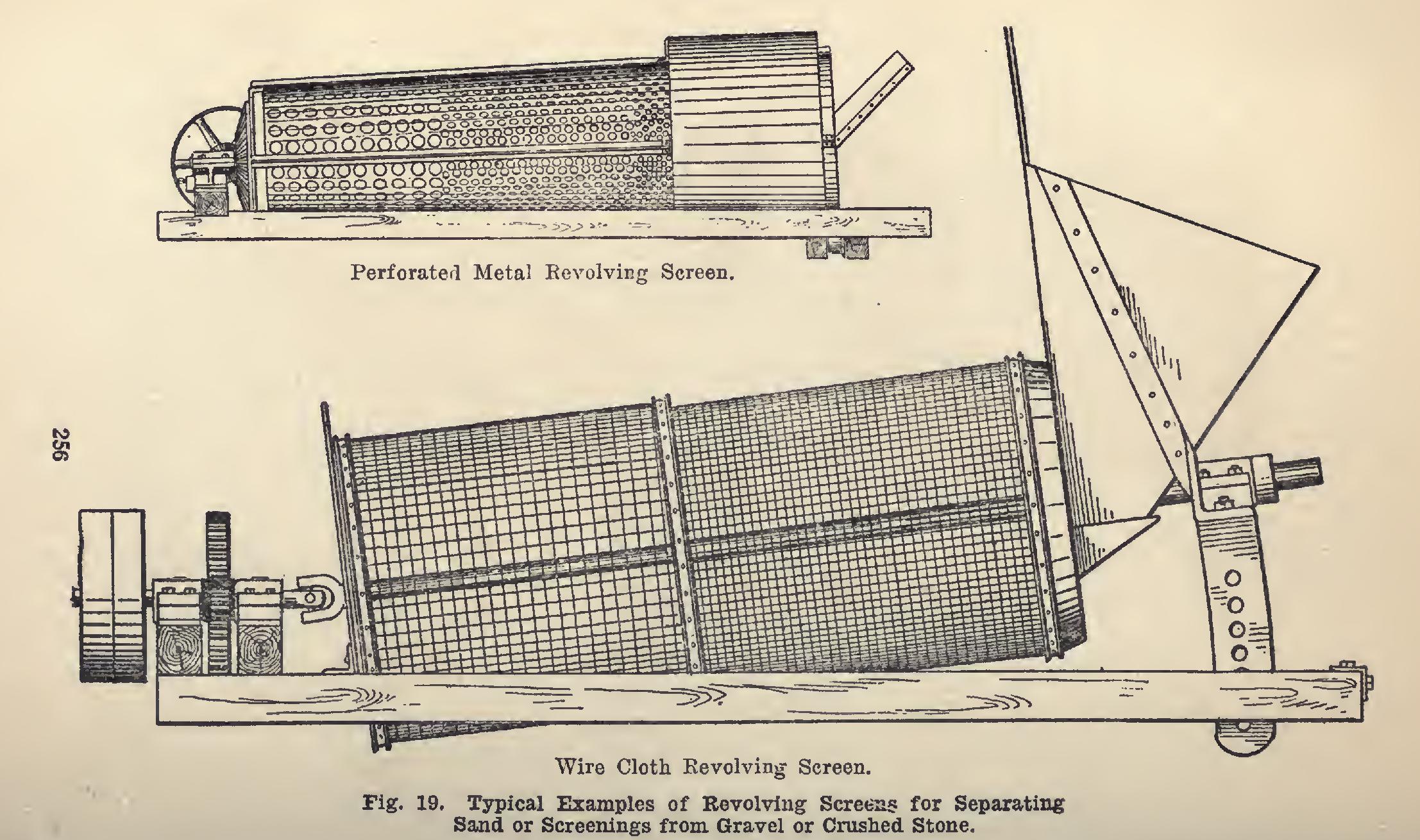

Very efficient machines of this class are found in the various types of revolving screens now on the market. Examples are illustrated in Fig. 19. These screens consist essentially of cylinders of perforated metal or wire cloth mounted at a slight incline and slowly revolving on a gear driven shaft. The finer meshes are at the upper end, the coarser at the lower end. The material to be screened is fed from a hopper or chute into the revolving screen at its upper end, and the successive sizes of ingredients are automatically separated by passing through the meshes as the material slowly find its way to the lower end of the screen.

Several important types of machines known as separators have been developed, consisting essentially of an inclined, mechanically vibrated screen, entirely enclosed so as to be dust-proof. One of "Newaygo" il lustrated in Plate 5 (lower figure). With ma chines of this class, the fineness of output is con trolled to a considerable extent by adjusting the supporting legs of the machine so as to change the inclination of the screening surface, which has the same effect as diminishing or increasing the screen mesh. The screen can be withdrawn for replacement or cleaning through a door at the upper end of the separator box, or through the hinged front cover.

In the case of the "Newaygo" separator, the feed conveyor distributes with regularity over the screen surface. A door at the back of the

conveyor box admits access to the feed-board and conveyor. The steel screen frame maintains a uniform tension of the screen cloth, promoting the vibratory impulses. The simple device for producing vibrations secures movements rapid and sharp, but of small amplitude. The design admits using either one or two screens, and any mesh cloth up to a fineness of one hundred.

The purpose of the machine is to separate all moderately dry, pulverized materials. The vi brations are sharp and cleansing, and give mate rial in process the least possible projection, offer ing it innumerable opportunities to pass through the clean screen openings before the tailings escape at the foot. The material is fed into the hopper, from which it is taken by a spiral con veyor and distributed in a continuous, thin stream over the entire cross-surface of the screen. The cloth is automatically kept in ten sion, and vibrated by the constant tapping of small hammers. As the material flows down the screen, the finer matter passes through the meshes, and the tailings escape over its foot The "Perfectecon" Separator is similar to the "Newaygo" in principle and in general ap pearance, but differs from it in some mechanical details.

A conveyor in a casing delivers the material over the edge of an adjustable feed-trough, in a steady stream of minimum thickness, which slides onto the vibrating surface of the screen cloth. This cloth is under adjustable ten sion, and is carried on a frame suspended from springs. Light reciprocating knockers, carried on rocking shafts, actuated by a crank on the conveyor shaft, deliver hundreds of light taps per minutue to the screen frame. These vibra tions are small but strong, and cause a constant and thorough vibration of the screen cloth, so that the material running over the screen is not thrown violently from it, but just projected suffi ciently to keep the meshes of the cloth clean, to assure a maximum capacity with a minimum screen wear, and a tailing free from fines. An outlet is provided for the tailings either through the bottom or the front. The bottom of the separator casing is very steep, having an inclina tion of over 50 degrees when in the average working position, to insure free flow of fines.