Specifications for Waterproofing Floors of Steel and Concrete Bridges

water, asphalt, action, oxygen, applied, sea and brine

The cause of the action of water upon asphalt appears to be in part chemical and in part physical. The mole cular structure of the asphalts is an important considera tion.

Asphalt has the property of physically absorbing a certain amount of water. This accounts in part for the increase in weight. Water also acts chemically upon as phalt to some slight extent—some of the loosely combined sulphur in the asphalt being replaced by oxygen, with the consequent liberation of hydrogen sulphide.

Throughout the course of the investigation it was ob served -that the waters that contained the smallest amounts of mineral matter produced the greatest action upon the asphalts. Sea water gave but little action. In order to obtain comparative results upon this point, samples of various asphalts were subjected to the action of distilled water, sea water, and a concentrated brine solution in glass jars. After two months it was found that the distilled water showed considerable action, the sea water a very slight action, and the brine no apparent action..

Some of the brine solution was also allowed to stand over the surface of an asphalt that had been already acted upon by water. No change in the brown material took place. This seemed to indicate that the salt itself exerted no chemical action upon the asphalt.

A determination of the dissolved oxygen in the dis tilled water, sea water, and brine gave the following re sults in cubic centimeters of dissolved oxygen per liter: Distilled water, 7.1; sea water, 4.8; brine, 0.6.

These facts show conclusively that the action of water upon asphalt is largely one of oxidation, and is due to the oxygen dissolved in the water. As a final test, however, a sample of Trinidad asphalt was covered with water which had been boiled until free from and then tightly sealed to prevent absorption from the air. The action that took place under these conditions was very slight. It appears, therefore, that water acts chiefly as a carrier of oxygen, and does not to any great extent give up the oxygen of its own composition.

The following asphalts and fluxes are arranged in the order of least to greatest action by water : Petroleum residuum.

Assyrian asphalt.

Asphaltina.

Cuban asphalt.

Alcatraz maltha, No. 2. Alcatraz maltha, No. 1. Alcatraz asphalt, D. Alcatraz asphalt, XX. Bermudez asphalt. Trinidad Lake asphalt.

The action of water upon asphalt is due to the unsat urated nature of the hydrocarbons present, and is at tended by a partial solution of the asphalt in the water. There is also a loss of sulphur as hydrogen sulphide, and an increase in weight of the asphalt itself due to oxida tion and to the mechanical admixture of water. By far the most important action which occurs is that produced by this oxidation of the asphalt by means of the dis solved oxygen in the water.

Cemeline. This liquid waterproofing is sup plied in various colors to accord with decorative schemes. Its proprietors claim for it perfect efficiency as an impervious coating on old or new stone, concrete, cement blocks, brick, wood, or metal, and as a durable and thorough water proofing and fireproofing. Cealtite is a plastic material, applied the same as putty, used as a cement filler for sealing cracks, open joints, or defects in plastered or cement construction.

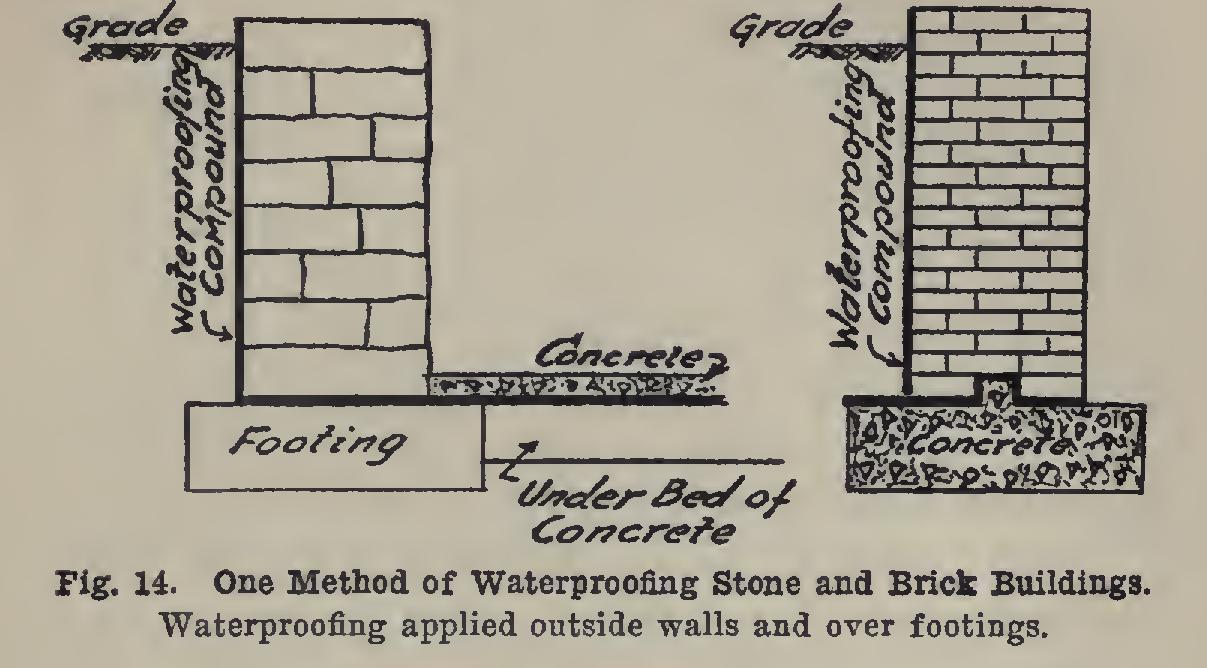

Dehydratine Damp-Resisting Compounds. These comprise a number of products intended to meet various conditions. They are heavy, black liquids which are applied cold with a brush, like ordinary paint. Their covering capacity is 50 to 80 square feet per gallon, depending on the condition of the surface; and two coats should be given. No. 1 is applied to the inner surface of exposed brick walls; and on the coating thus formed, plastering may be done directly. No. 4 is intended for work below grade. In water proofing a basement, for example, two coats of compound should be applied on the footings be fore the foundation walls are built; when the concrete floors are being laid, two coats should be applied between the layers of concrete; after the foundation walls have been erected and be fore the back-filling is done, two coats should be applied on the outside and carried up above grade, being protected from abrasion, while back-filling, by sticking burlap or building paper to the tacky coating. See Fig. 14.