Chimneys Roofs

shingles, roof, cement, concrete, plate, type and ing

Every fire test of properly made concrete, whether made by Fire Underwriters or the Gov ernment Laboratories, proves this modern build ing material to be a most effective fire-resistant. This advantage alone, without doubt, has, more than any other factor, placed concrete roof cov ering in the position it now holds. The permanently waterproof qualities of concrete roofing also give it an advantage over other types of roofing likely to be affected by the heat of the sun and the destructive work of the elements.

The "Diamond" cement shingle is adapted to all manner of roofs, hips and valleys, without the necessity of cutting or fitting. It is made by the "face-down" process. These shingles are nailed to the sheathing with sixpenny wire nails. No expensive copper wires are needed. Where roofing is wired on, it is difficult to use paper or felt; but where nails are used, as with the present type, it is claimed that the use of slater's felt or tarred paper is not only possible but desirable. See Plate 2.

The Grumman cement shingle is a type of the reinforced class, being reinforced with expanded metal lath. The fact that the operator finishes the shingles—as also the floor tile made under the same system—on the top or face, enables him to color his shingles and tile any desired color by mixing cement and coloring, equal parts, and sifting on shingle or tile, then trowel ing off to a finish. See Plate 2.

Another type of the cement shingle is the "Superior." They are of suitable dimensions for any style of building on which shingles, slate, or tile may be used. They do not hang loose on the nails, but are nailed down like wood shingles. The abestos nail-pads being sufficiently pliable to take care of any contraction or expansion, and, by reason of their peculiar construction, render ing impossible capillary attraction of moisture. With their wire reinforcement it is claimed that they are much stronger than any slate and prac tically everlasting, while at the same time adapt ing themselves well to ornamentation.

They are laid on the roof 7 inches to the weather, thus requiring 294 to the square. The weight is 600 lbs. per square. The cost to manu facture may be easily estimated, calculating 400 lbs. of sand, 200 lbs. of cement, with the asbestos nail-pads and wire reinforcement, all subject to local market conditions, which, as well as labor, differ in various localities.

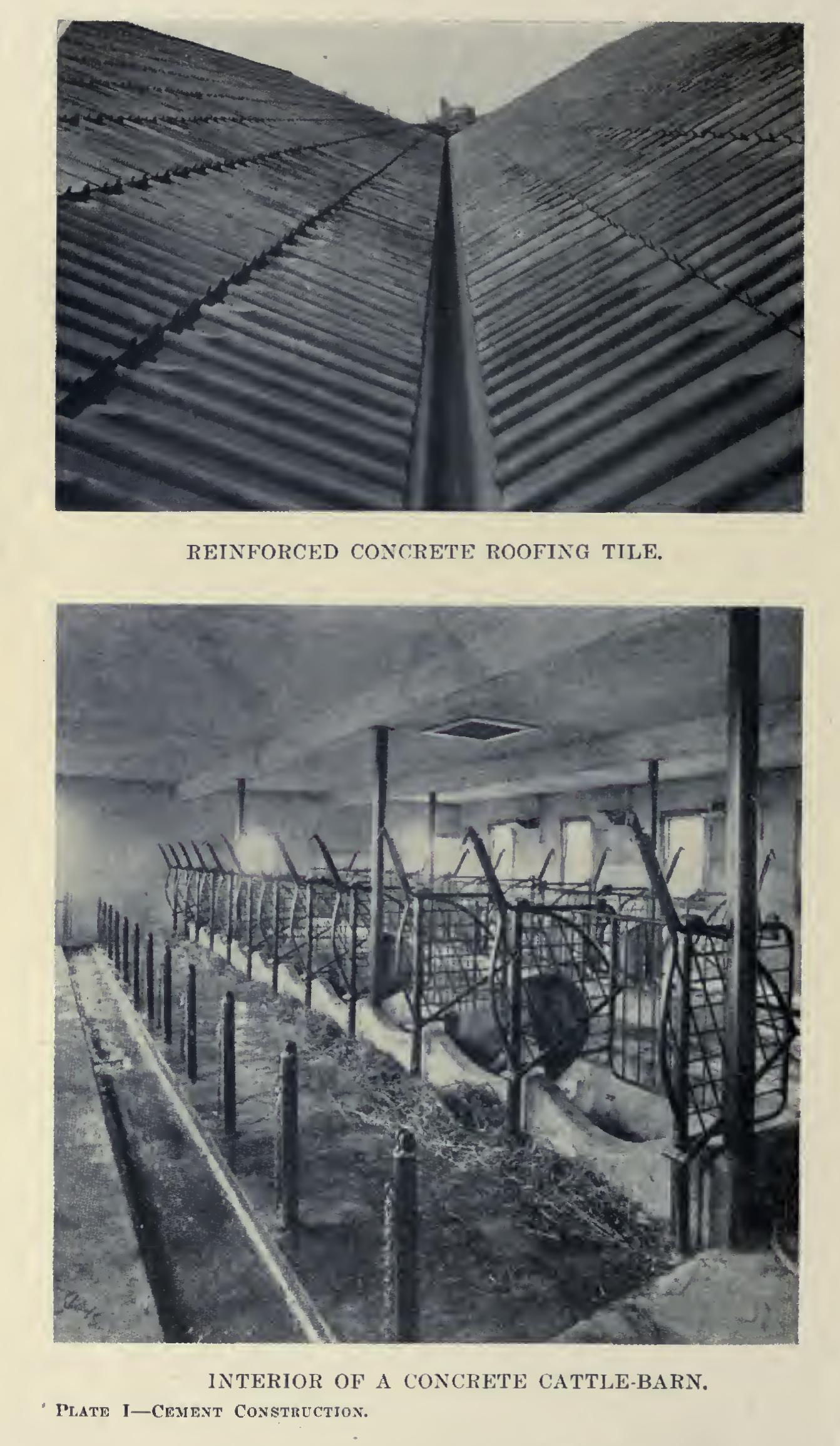

A form of reinforced concrete roofing that requires no centering is exemplified in the "Ferro-Lithic" plate. This type of roof plate consists of iron sheeting so corrugated that the openings at once form a bond for concrete on the exterior and plaster underneath. These plates are used also for siding, stairways, floors, etc., and form both permanent centering and rein forcing. They are quickly laid in place, and easily concreted on top and plastered on the under side. See Plate 3.

The vertical portion of the dovetails serves as ample reinforcing, being greatly assisted by the mechanical bond secured by the heavy cross-ribs.

When completed, this roof is claimed to be the lightest type of reinforced concrete roof on the market—a fact of considerable value in the design of roof trusses.

Inflammable roofs are a constant source of fire communication, but this roofing is fire-resist ant and protective. It may be laid and used without concreting, during stormy or wintry weather, and concreted at a more favorable season.

Asbestos Shingles. A combination of asbes tos and Portland cement has been produced, which, when made up in the form of shingles, furnishes a roof that is absolutely fireproof. The shingles are made under high hydraulic pressure. Simple exposure to the elements causes the ce ment that has been deposited in the asbestos fiber to crystallize, and the material then be comes better, tougher, and harder as time goes on.

Another good point for these shingles is that they do not need paint, or any attention, as the elements take better care of asbestos shingles than any paint or dressing.

These shingles, owing to their composition, are sufficiently elastic to allow of marked tension due to vibration, expansion, and contraction of surrounding parts, etc., without breaking, cracking, or tearing apart. Their resistance to blows, tensions, or lesions of any sort is said to be surprising. They can be worked easily with ordinary tools. They become very hard in time, especially when exposed to the weather.

They are usually applied by the French, or diagonal, method. Shingles for a finished roof, laid in this manner, weigh about 250 pounds to the square. This lightness, with its accompany ing efficiency, renders them peculiarly adaptable to lighter construction.