Concrete Tanks and Cisterns

cistern, sand, inches, wall, feet, thick and bottom

Inlet and outlet holes may be made by put ting pieces of pipe in place before filling in the concrete, or a greased, tapering wooden plug to be drawn out when concrete has set.

A trough with a solid concrete base should be made in the same general way, the forms car ried up to the desired height of trough, and the reinforcing embedded in the concrete a few inches from the inside. Troughs should be pro tected from the sun and currents of air for sev eral days, and kept wet by sprinkling.

The method of construction of a small con crete tank is plainly shown in the accompany ing illustration (Fig. 25). A tank of this size is suitable for ordinary purposes. See also Plate 6.

A

Concrete Cistern. The mixture for a cis tern should be made of one part cement and three parts sharp sand. The two should be mixed dry, and water sufficient to make a stiff mortar should be added. If the soil is of clay or of such a character that there will be no dan ger of a cave-in, it is not necessary to wall up with brick. The mortar should be applied about one-half inch thick, and should be followed im mediately with a second coat one-fourth of an inch thick. Then give a skim coat made of equal parts of cement and sand. Keep the surface moist a week, and do not fill with water until 10 or 12 days. See Plate 7.

Cisterns made in this manner are usually built egg-shaped, with the use of falsework for crowning the top, in which case the skim coat cannot be added. The walls in egg-shaped cis terns should be two inches thick at the bottom, three-quarters of an inch on the side, and three inches on the crown. If there is to be more than the ordinary pressure on the crown, it can be reinforced with wire netting. Local conditions must favor this method; it will not answer in all cases. A four-inch brick wall laid in cement mortar (one part cement and two parts sand), and plastered on the inside a half-inch thick with the same mortar, waterproofed, is in most cases satisfactory. But to make the cistern ab solutely water-tight, let the wall become hard, which requires six or eight days.

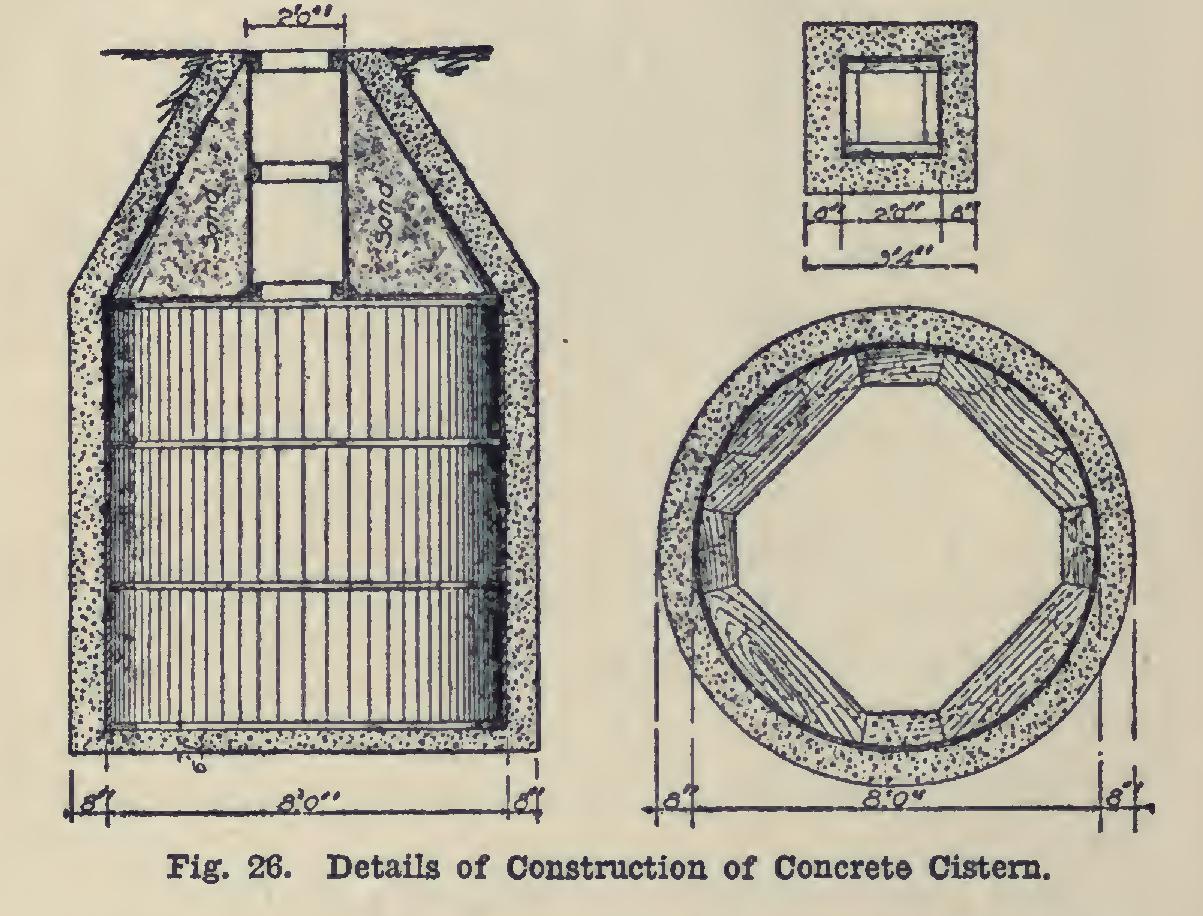

For a round cistern of large dimensions, make a circular excavation 16 inches wider than the desired diameter of the cistern, or allow for a wall two-thirds the thickness of a brick wall that would be used for the same purpose, and from 14 feet to 16 feet deep. Make a cylindrical

inner form the outside diameter of which shall be the diameter of the cistern. The form should be about 9 feet long for a 14-foot hole, and 11 feet long for one 16 feet deep. Saw the form lengthwise into equal parts for convenience in handling. Lower the sections into the cistern and there unite them to form a circle, blocking up at intervals six inches above the bottom of excavation. Withdraw blocking after filling in spaces between with concrete; and then fill holes left by blocking, with rich mortar.

Make concrete of one part Portland cement, two parts clean, coarse sand, and four parts gravel or broken stone. Mix just soft enough to pour. Fill in space between the form and the earth with concrete, and puddle it to pre vent the formation of stone pockets, using a long scantling for the purpose, and also a long handled paddle for working between the con crete and the form.

To construct the dome without using an ex pensive form, proceed as follows: Across the top of the form build a floor, leaving a hole in the center two feet square. Brace this floor well with wooden posts resting on the bottom of the cistern. Around the edges of the hole, and rest ing on the floor described, construct a vertical form extending up to the level of the ground.

Build a cone-shaped mould of very fine wet sand, from the outer edge of the flooring to the top of the form around the square hole, and smooth with wooden float. Place a layer of con crete four inches thick over the sand, so that the edge will rest on the side wall.

Let the concrete set for a week; then remove one of the floor boards, and let the sand fall gradually to the bottom of the cistern. When all boards and forms are removed, they can easily be passed through the two-foot square aperture, and the sand taken out of the cistern by means of a pail lowered with a rope. This does away with all expensive forms, and is per fectly feasible. The bottom of the cistern should be built at the same time as the side walls, and should be of the same mixture, six inches thick.