Form Construction

concrete, days, time, weather, foreman, summer, oil and times

Use of Oil. Crude oil is one of the best ma terials to prevent adhesion of the concrete to forms, though linseed oil, soft soap, and various other greasy substances are also employed for this purpose. The oil or grease should be thin enough to flow and fill the grain of the wood.

If the forms are to be left on until the con crete is hard, there is little danger of the concrete sticking to them if they are wet thor oughly with water before the concrete is laid instead of being greased. In any case, if concrete adheres to the forms it should be thoroughly cleaned off before resetting; even then it is apt to stick again in the same place.

Protecting the Forms.

After the falsework is once placed, it should be protected against severe temperature changes, and against rain or snow. If it is necessary to leave the form work empty for any length of time, then, before pour ing the concrete, it should be gone over again carefully, the shrinkage joints being repaired and the bracing and supports tightened up. In warm weather, wet the forms before placing concrete; otherwise the lumber will absorb the water in the concrete, and cause honeycombing.

For form boxes of columns or beams, 2-inch timber is recommended; for floor slabs, 1-inch boards on 2 by 8-inch joists, spaced 16 to 24 inches apart, according to thickness of slab; for posts, 4 by 4 inches spaced from 3 to 8 feet apart, according to the height and the dimensions of beams and slabs; for bracing and cross-bracing, 2 by 4-inch.

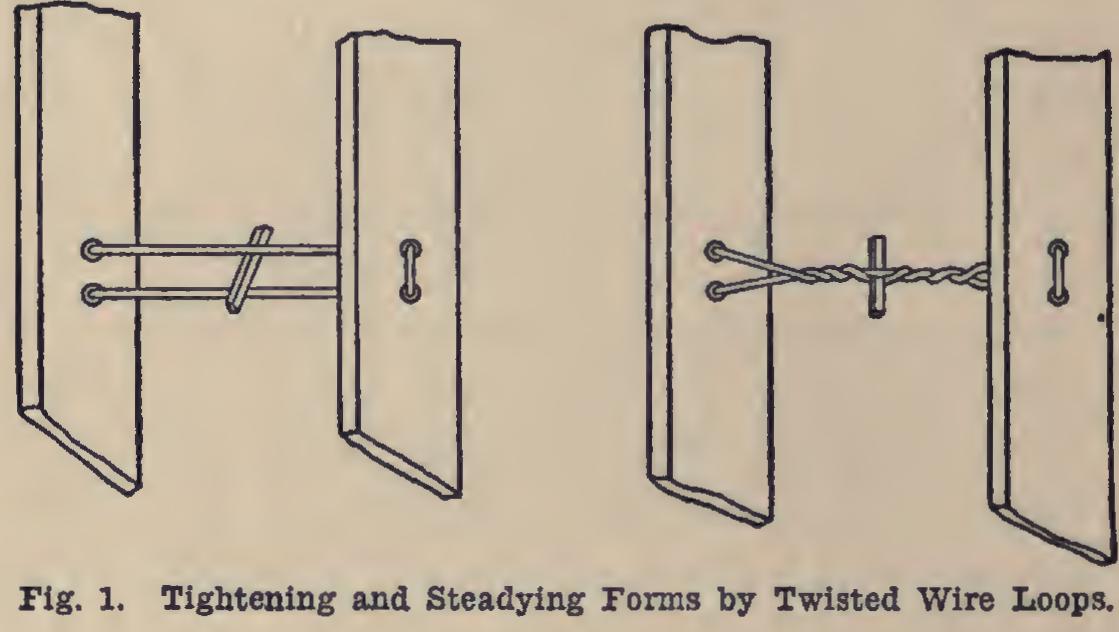

The skilful superintendent or foreman may be recognized by the scarcity of nails he uses. Column boxes should be securely clamped, and beam boxes so framed that the floor joists prac tically hold the sides without nailing. If the removal of centering necessitates the use of the long prying crowbar with three laborers at its end, the foreman should be fired.

There should be one foreman, at least, for every twenty carpenters, and a head carpenter foreman in charge of all falsework.

Time to Move After Placing.

The best con tractors have definite rules for the minimum time the forms must be left in ordinary weather; and then these times are lengthened for changes in conditions according to the judgment of the foreman.

Conference with a number of prominent contractors in various parts of the country indi cates substantial agreement in the minimum time to leave forms. As a guide to pratice, the following rules are suggested, these following in the main the requirements of one large con struction company: Walls in mass work—one to three days, or until the concrete will bear pressure of the thumb without indentation.

Thin walls—in summer, two days ; in cold weather, five days.

Slabs up to 6 feet span—in summer, six days; in cold weather, two weeks.

Beams and girders and long-span slabs—in summer, ten days or two weeks; in cold weather, three weeks to one month. If shores are left without disturbing them, the time of removal of the sheeting in summer may be reduced to one week.

Column forms—in summer, two days; in cold weather, four days, provided girders are shored to prevent appre ciable weight reaching columns.

Conduits—two or three days, provided there is not a heavy fill upon them.

Arches—of small size, one week; for large arches with heavy dead load, one month.

All of these times are, of course, simply ap proximate, the exact time varying with the temperature and moisture of the air and the character of the construction. Even in summer, during a damp, cloudy period, wall forms some times cannot be removed inside of five days, with other members in proportion. Occasionally, too, batches of concrete will set abnormally slowly, either because of slow-setting cement or because of impurities in the sand; and the foreman and inspector must watch very carefully to see that the forms are not removed too soon. Trial with a pick may assist in reaching a decision.

Beams and arches of long span must be sup ported for a longer time than short spans, because the dead load is proportionately large, and therefore the compression in the concrete is large even before the live load comes upon it.

The general uncertainty, and the personal element which enters into this item, emphasize the necessity for some more definite plan for insuring safety. The suggestion has been made that two or three times a day a sample of con crete be taken from the mixer and allowed to set on the ground under the same conditions as the construction until the date when the forms should be moved. These sample specimens may be then put in a testing machine to determine whether the actual strength of the concrete is sufficient to carry the dead and construction loads. Even this plan does not provide for the possibility of an occasional poor batch of con crete, so that watchfulness and good judgment must also be exercised.