Rules Specifications

concrete, mixer, stone, cubes, cent, contractor, percentage and plant

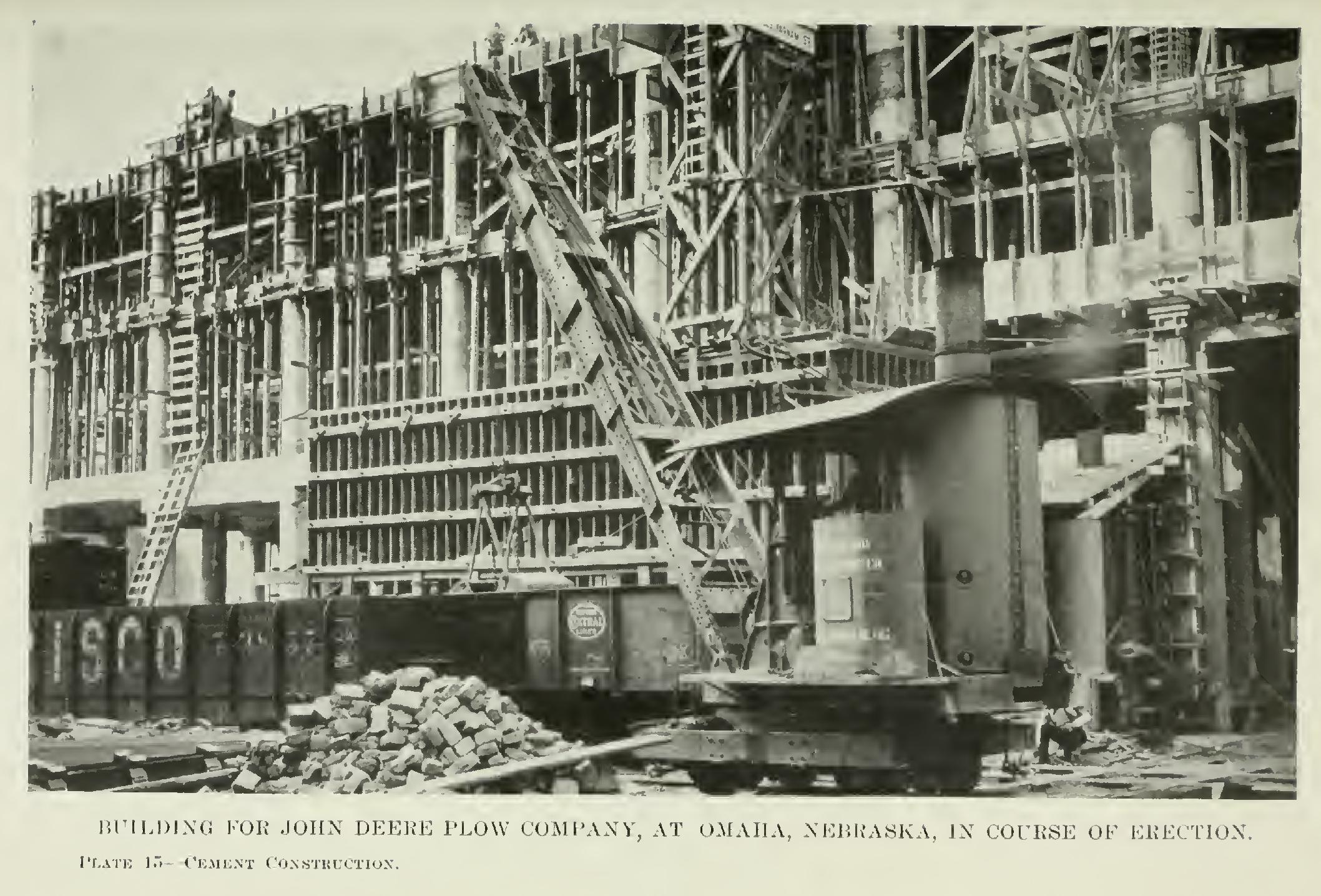

"Contractor's Plant and Construction Work. Don't hurry your contractor until he has had a reasonable time to get his plant together. Good work cannot be executed with a poor plant at what are ordinarily reasonable prices. It is suggested to the contractor to bear in mind that stone crushers and concrete mixers seldom have enough power behind them to produce their rated capacity. Concrete mixers should be selected which have been in successful use. To get concrete to and from the mixer is more difficult than to mix the concrete. Mixing by hand in small quantities and at isolated points is fre quently cheaper than machine. A first-class concrete plant will cost from 5 to 10 per cent of the total cost of the work. Besides handling concrete, the plant, as a rule, has to do the following work (difficult foundation not considered) : Excavate ; sheet-pile ; mix and transport mortar; mix and transport concrete ; handle lumber for falsework and forms (including demolition) ; handle steel, coal, broken rock ; and back-fill. Several of these items should be carried on at one time to execute the work economically, which gives preference, as a rule, to derricks rather than cableways.

"Mixer. In selecting a mixer, give preference to a batch mixer which has been in successful operation a number of years. In this connection, however, I wish to say that the best tests I have ever had' were from a con tinuous mixer of the asphalt type ; but I think it requires more careful inspection to use this machine than it does the batch mixer. In such work as arch work, where a large monolithic day's work is necessary, be careful to select a mixer which does not easily get out of gear.

"If the contractor is to use a machine which is not known to you, or if you are not satisfied with the con crete which it is turning out, I would suggest the fol lowing test. I have found it a very valuable one on my work. In one case I found that a mixer whose product did not size up well to the eye was only giving me 60 per cent strength of what might be regarded as a first class concrete. An experienced man would probably be able to detect the fact that the results were bad, but even experience can well be supplemented by practical test.

"Take the concrete as it comes from the mixer, and from this concrete take several handfuls of mortar from different parts of the pile until you have a shovelful. Then, being careful not to mix this mortar at all, make six briquettes from it. Then take several shovelfuls of eoncrete from the different parts of the pile of concrete, until you have enough for six cubes. These cubes should be at least four times as large as the largest dimension of the broken stone used in the concrete, and preferably they should be 12-in. cubes, if there is an accessible

machine large enough to crush sueh a cube. In making up the cubes, be careful not to mix the concrete. After you have made the briquettes and cubes just described, have the remaining concrete turned over by hand four times. Then repeat the sampling, making six briquettes and six cubes. Then store the two sets of briquettes and the two sets of cubes under exactly the same condi tions, and break them in from seven to thirty days. The latter is preferred if you can take the time. The tests of the second set of the briquettes and cubes should not show an increase in strength of 10 per cent over the first set. However, if over 10 per cent and less than 15 per cent, I would suggest a second test, the results of which should be final.

"Lean mixtures require more mixing than rich ones. Dry mixtures require more mixing than wet ones.

"In feeding a continuous mixer by shovel, see that all of the material is fed at the loading end. It is not uncommon to see at least one of the shovel men feeding his material at the dumping end. Permit the retempering of concrete where the set is not so hard as to require a pick, provided the practice is not habitual. Do not split hairs on the mathematical proportions of the several materials which make up your concrete. This frequently causes a lot of squabbling with the contractor without good resulting from it. Don't make the contractor pick out every piece of string, twig, or leaf which you happen to see going through the mixer.

"Materials—Gravel. Do not accept slimy gravel (when wet), nor gravel containing many mud balls, or a large percentage of gravel cemented with mud.

"Broken Stone. Do not accept stone with a large percentage of tailings, nor stone with more than 15 per cent of stone dust, nor more than 1 per cent of weathered rock, nor stone a noticeable percentage of which goes to pieces under the rammer. My objection to a large percentage of stone dust is that, as a rule, rock which, when crushed, gives a large percentage of dust generally contains considerable rotten rock, which is ground to dust in its passage through the crusher. In using run-of crusher material, study crusher conditions so as to obtain a reasonably uniform product.

"Cement. The cement house should be sufficiently large to store about 20 per cent of the annual work; or, what is practically the same thing, it should be large enough for two months' storage. The house should be of such size that the cement can be piled and kept in separate car lots.