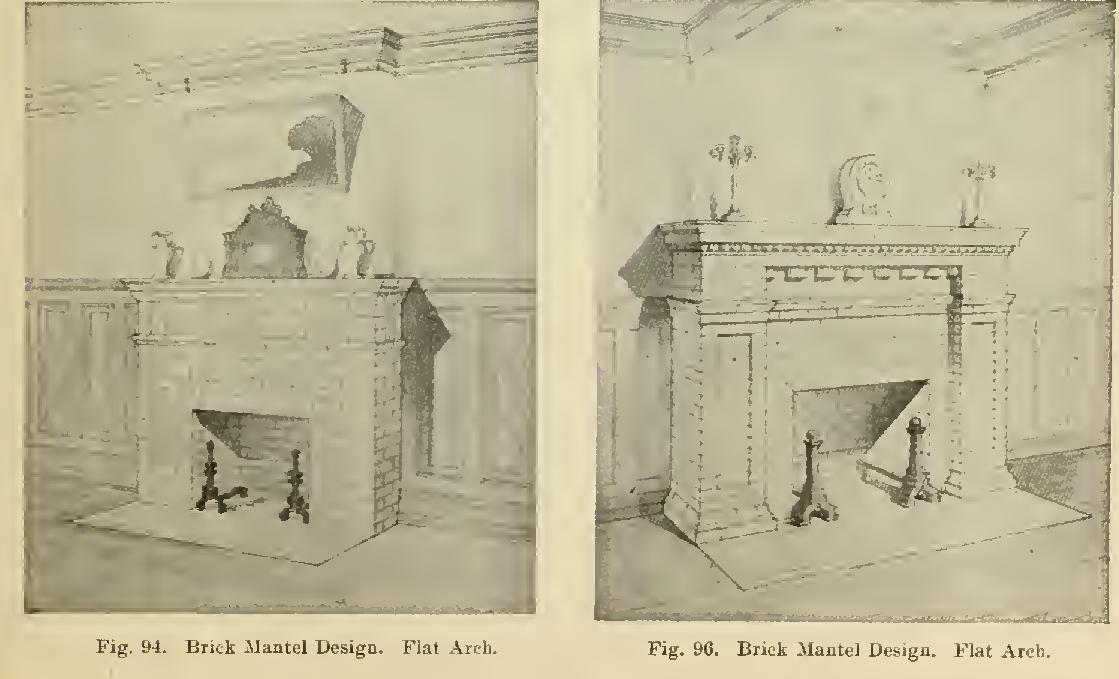

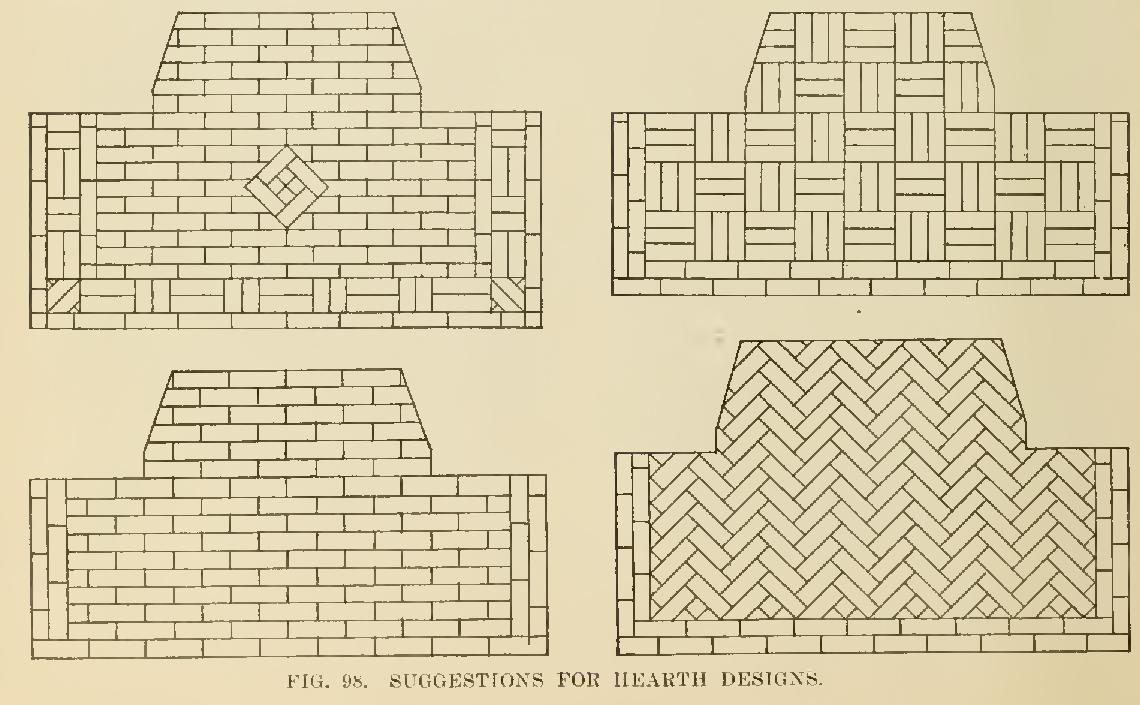

Brick Fireplaces

inches and top

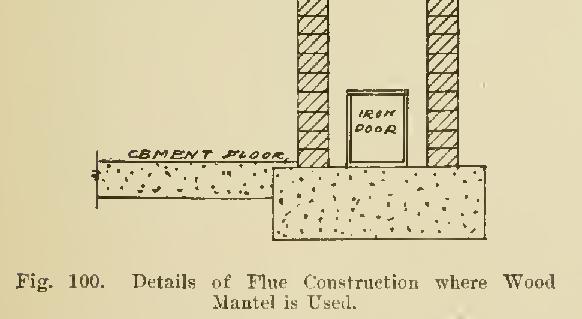

Cast-iron hoods with damper attachment are quite often used to form the top of open fireplaces, and are set in place at the time of building the chimney. The top should be capped with Portland cement, or with a 3 or 4-inch flat stone with openings cut to fit the flue openings.

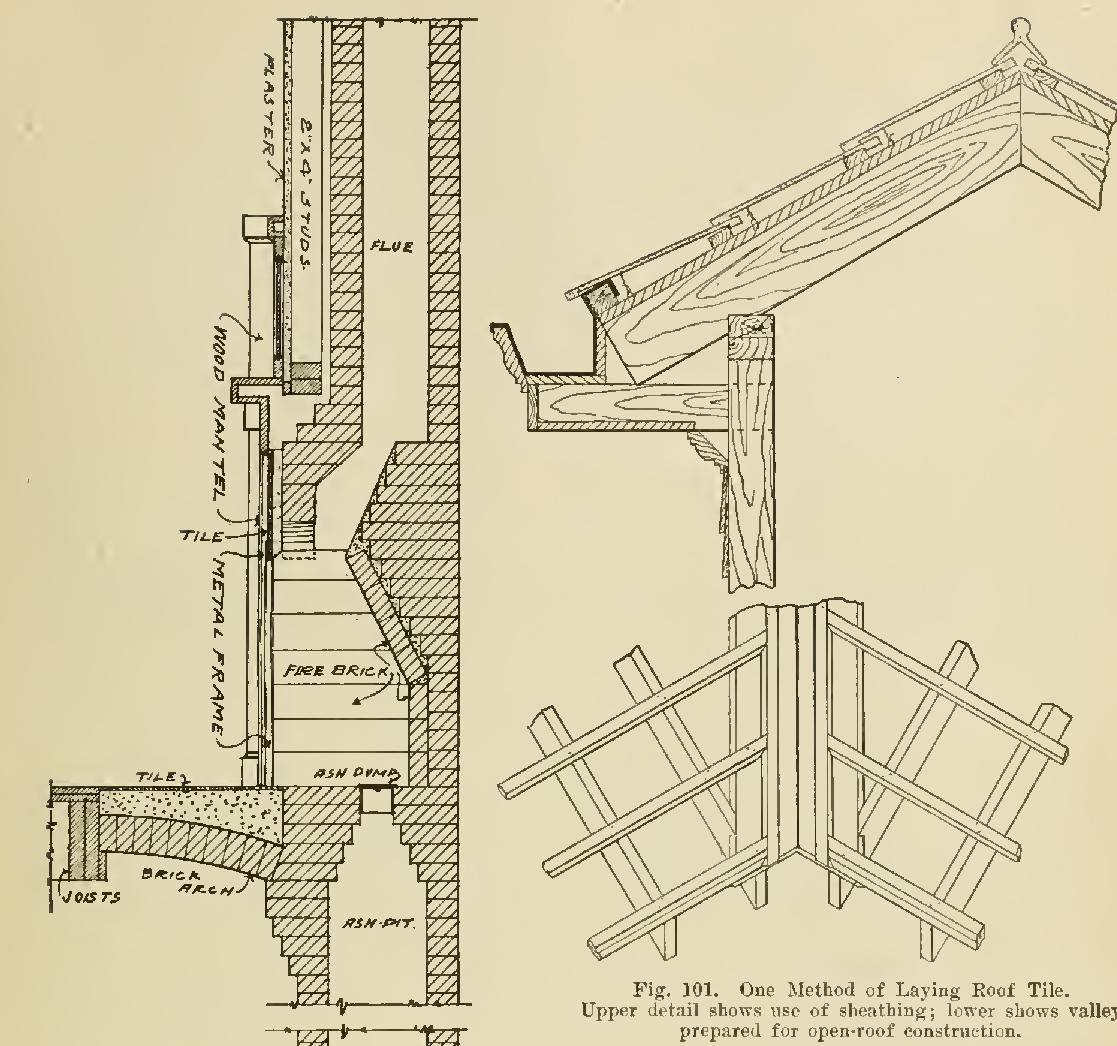

Framing for Heavy Roofing—Tile.

There are some special features that should be noted in regard to the proper framing of a tile roof and its preparation to receive roofing tile. Rafters should be at least 2 inches by 6 inches, and 24 inches on centers, or closer, according to length of span. Sheathing should he securely nailed, and should be either of common lumber laid tight and well joined together, or of matched and dressed sheathing securely fastened. The roof pitch may be as low as one-fourth (provided slope is not of extreme length), and from that to the vertical.

'Before the tile are laid, the entire roof should be carefully covered with one layer of good roofing felt, laid to lap 2 inches in every course, and to be turned up against the sides of the building at least 4 inches. If the building has a box or cornice gutter, felt should lap over top of metal at least 4 inches, and the same at valleys. After felt is so laid, same should be stripped with good white pine plastering lath, laid parallel, true, and straight, to facing board at eaves. The top edge of first line of lath should be 12 inches above the lower edge of facing board or starting strip; and thereafter not less than 12 inches nor more than 121/4 inches space allowed from the top edge of each line of lath to the top edge of the next above and parallel. The tiles hook over these strips; and each tile is fastened with a seven-penny galvanized-iron or copper wire nail.

All ridge-boards should extend 3 inches above top of sheathing, and hip hoards inches, and both be of inch common lumber. Facing board or starting strips at eaves under bottom end of tile, will extend up above the top edge of sheathing 1% inches. In all cases facing boards at gable ends should be flush with the sheathing.

In some cases an open roof construction is used—that is, one with no sheathing under the tile. In that case, there must be a space of 12 inches between the lower edge of the lowest purlin to top edge of the purlin next above it, and thereafter a space of not less than 12 inches nor more than inches between the top edge of each purlin to the top edge of the purlin next above it. These purlin strips

should be inch by 2 inches or over, the bottom strip 11/4 inches higher than the strip next above it—that is, 2% inches by inch. In this construction the hip and ridge strips should be the same as if the building were sheathed.

Segmental Arches in Brick Walls. The word "segment"-means a portion or part of a circle. In point of fact, any arch struck from one center, and being less than a semicircle, is properly termed "segmental." The most common use of the segmental arch is perhaps, as a relieving arch over the lintel of an opening for a door or window in a brick wall. In such cases, no better proportion can be taken than one-sixth of a circle. There is, however, an important point of construction involved, and one that is often neglected.

Fig. 103 shows two relieving arches, one being laid out in the wrong way, and the other correctly. The first is wrong because, in the case of fire, the wooden lintel would be consumed, and the thrust of the arch on the burnt end would be bound to cause a failure and endanger the whole of the wall above.

A better way is shown. Instead of making the span of the relieving arch equal to the opening between the jambs below, the arch springs from a point over the extreme end of the wooden lintel. In case of fire occurring and the lintel being entirely consumed, the arch would be unaffected, and would continue to carry the weight above. Building inspectors and managers should insist on the adoption of this correct method, for it costs no more than the incorrect one, and the advantage of it in ease of fire is greatly in its favor.

Of course, for such arches, no elaborate centering is necessary. The lintel is laid in position; and a piece of inch stuff is shaped to the curve of the arch, and laid upon the lintel to form the centering. The arch is then turned upon this centering, which is removed when the mortar is properly set, the core being then filled in with brickwork.