Framing for Brick Houses

wall and construction

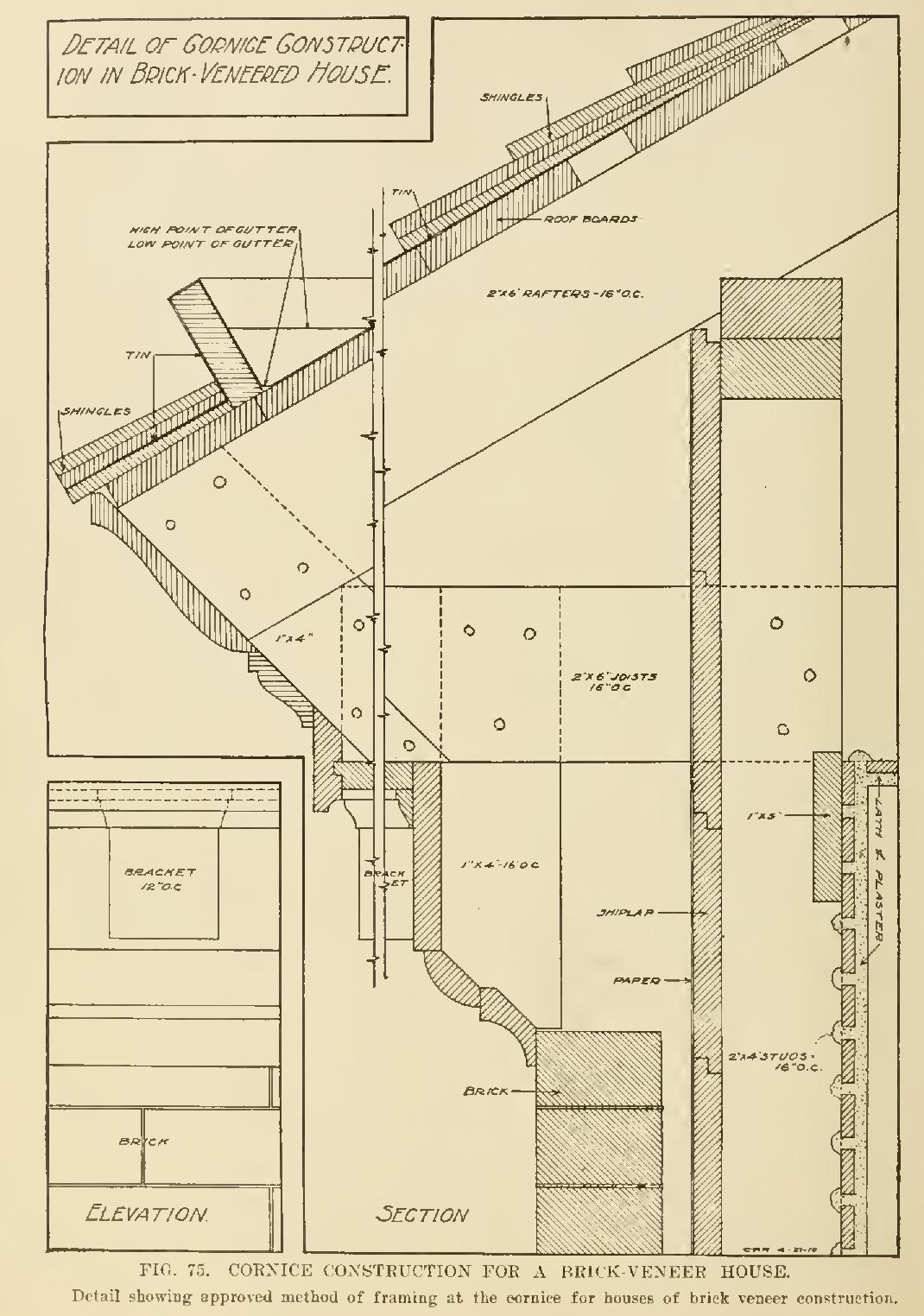

The hollow space serves a double purpose, as it affords a dead air-space, and at the same time allows some leeway in correcting unevermess in the framework. It is also a good idea to cut-in pieces between the joist and studding at the different floors, so as to cut off the circulation in case of fire, as well as prevent the movements of the ever pesky mouse.

The anchoring of the brickwork to the sheathing should be done by stapling wire to the sheathing opposite the studding and about every sixth course apart. The wire should be left loose enough to reach out half the width of the brick, and to be well bedded into the mortar joint. No. 11 wire should be used.

Comparative Cost of Veneer and Solid Brick Construction.The question of comparative costs is one which the contractor or builder often has to face; and, unless experience has given him the desired knowledge, he is often troubled as to how to proceed in the matter. As an example, we shall show an approximate method of determining the difference in cost between a houSe in brick veneer construction, and the same size of house in solid brick.

On accomat of the roof, foundations, floors, windows, doors, all interior finish, etc., being practically the same in each house, we shall confine ourselves to a comparison of the costs of the walls in each form of construction.

The difference in cost of plain wall construction for the two forms of construction is approximately as follows: Brick veneer (Based on cost of face brick at $21.00 per 1,000) Dimension lumber, S ft. B. III., at 4c. per ft (in wall) $0.32 Sheathing, 10 ft. B. II., at 40. per ft. (in wall) .40 Building paper, put on, per yd. .03 63 face brick, at 31/2c. each (in wall) 2.21 Plastering, three coats, per yd. .26 Total, per sq. yd. $3.22 Solid brick (12-inch wall) 03 face brick, at 3r/c. each (in wall) $2.21 126 common brick, at $14 per 1,000 (in wall) 1.76 Furring walls, per yd. .06 Plastering, three coats, per yd. .26 Total, per yd. $4.20 The above figures will give a fair idea of the comparative wall costs. Of course, the percentage of the total cost of these two houses will not be directly proportional to these above costs, since the latter are only a part of each total. By adding to each one the cost of floors, roof, interior finish, etc., divided by the total number of .square yards of wall surface, we should then be in a position to give a comparative estimate on the total cost of the forms of construction. This percentage of the total cost is often figured as being 13 to 20 per cent greater for solid brick strnetion than for veneer.

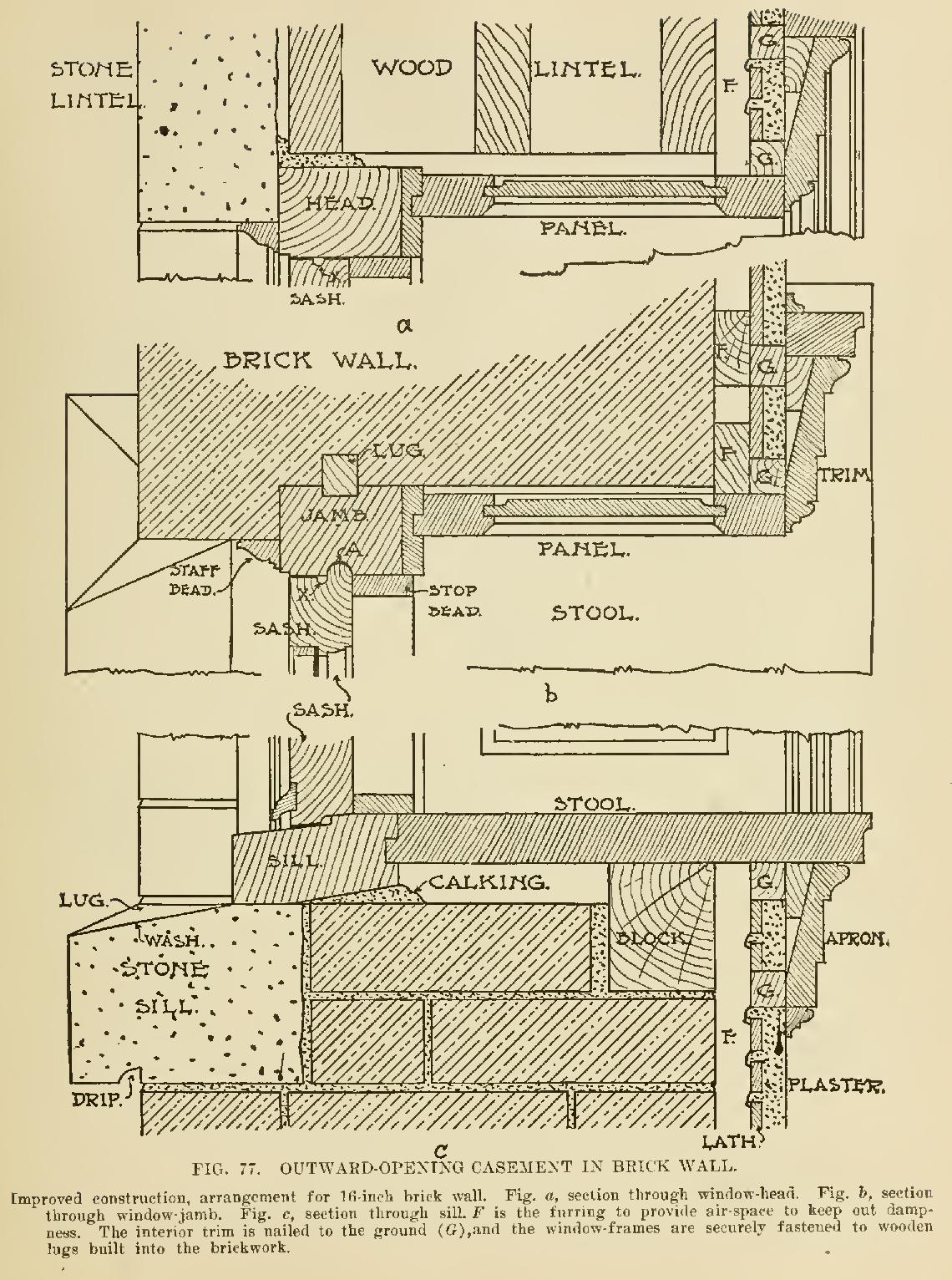

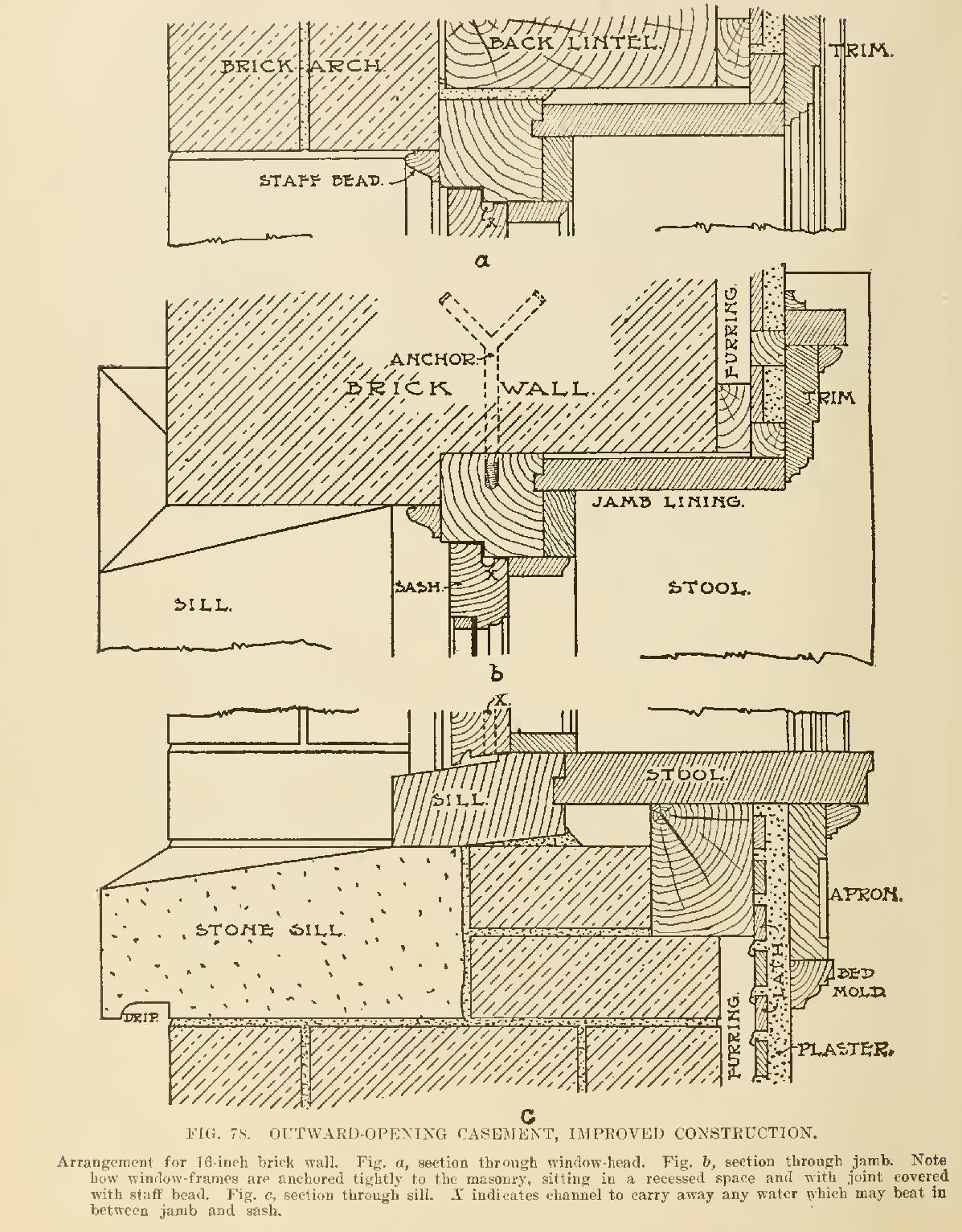

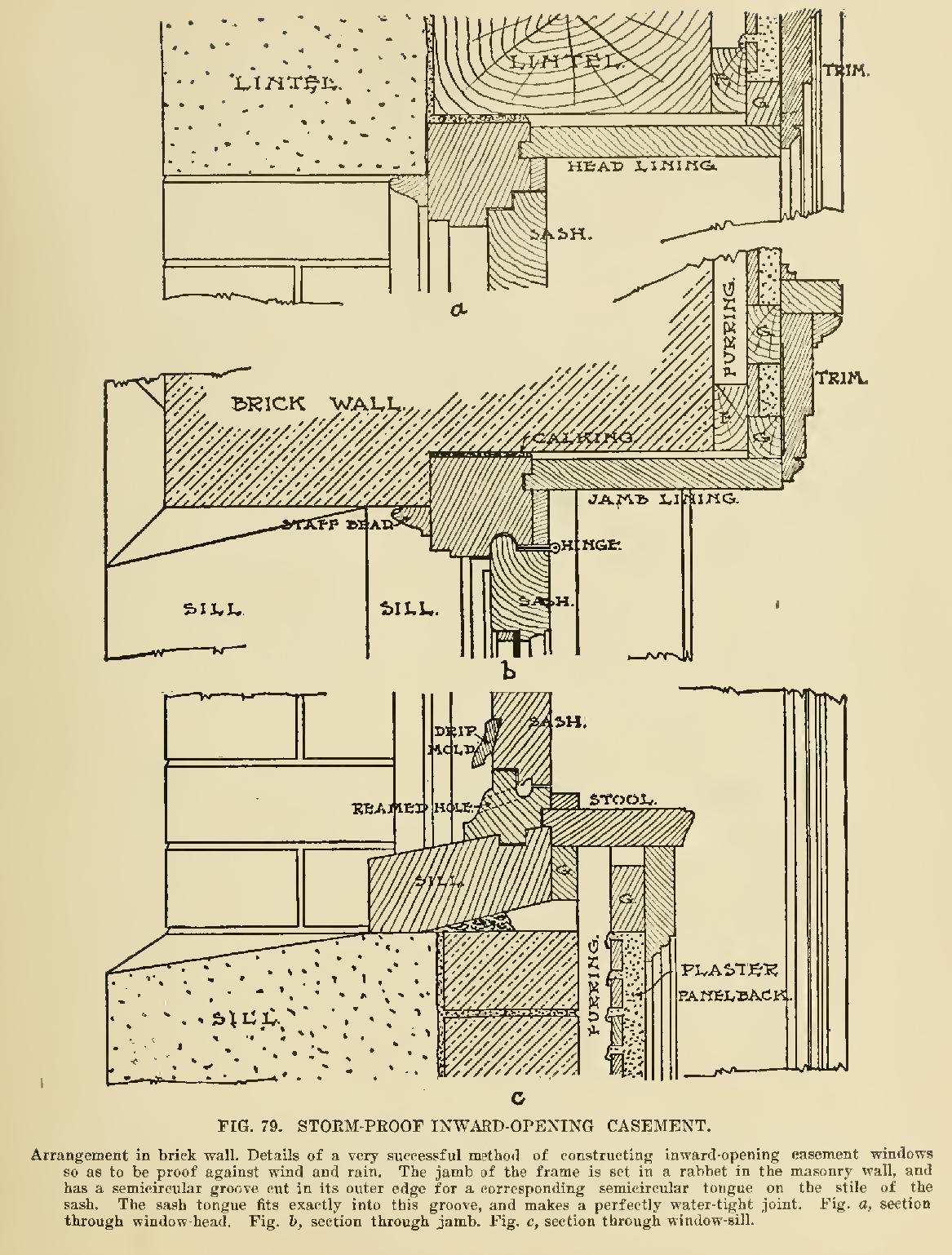

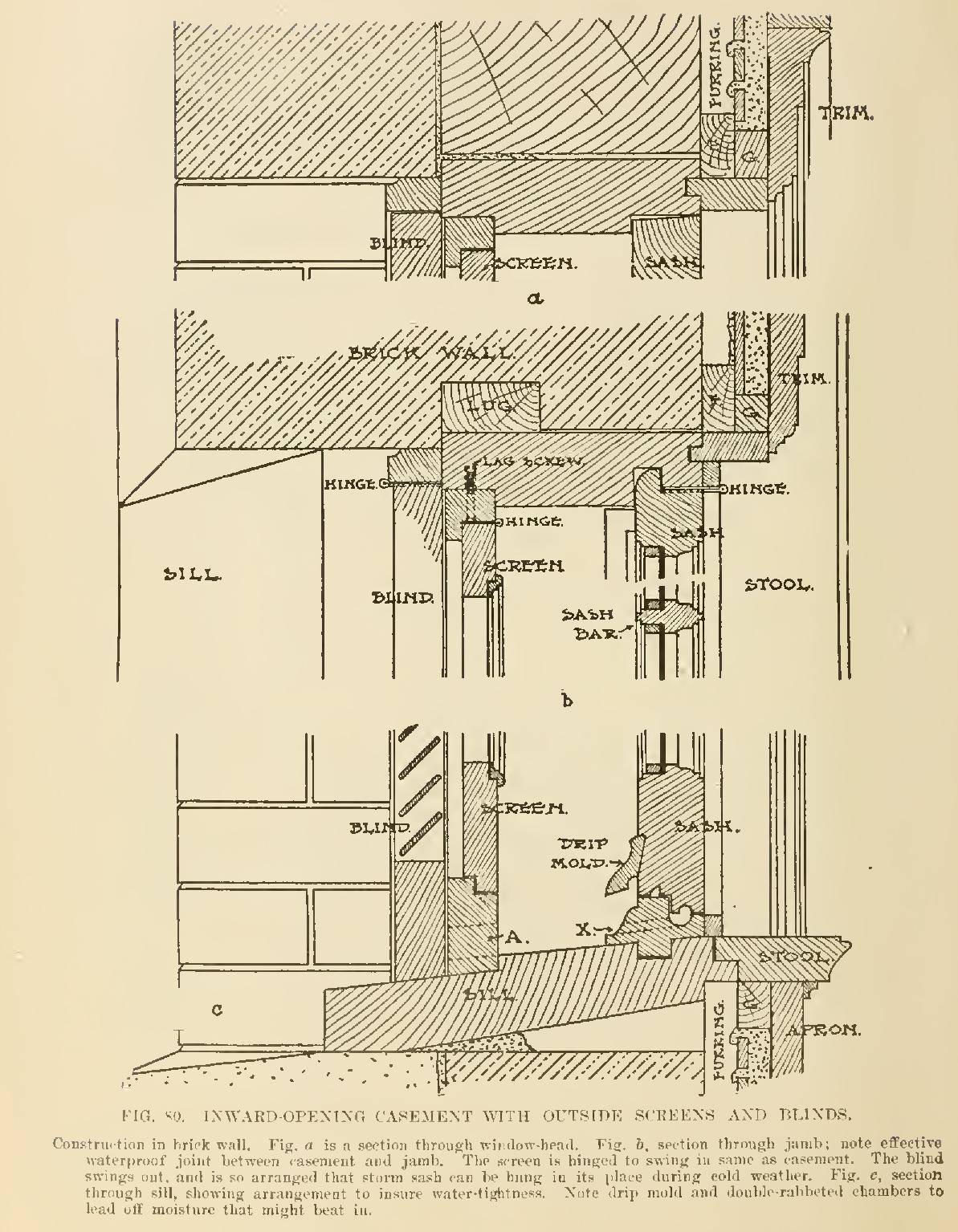

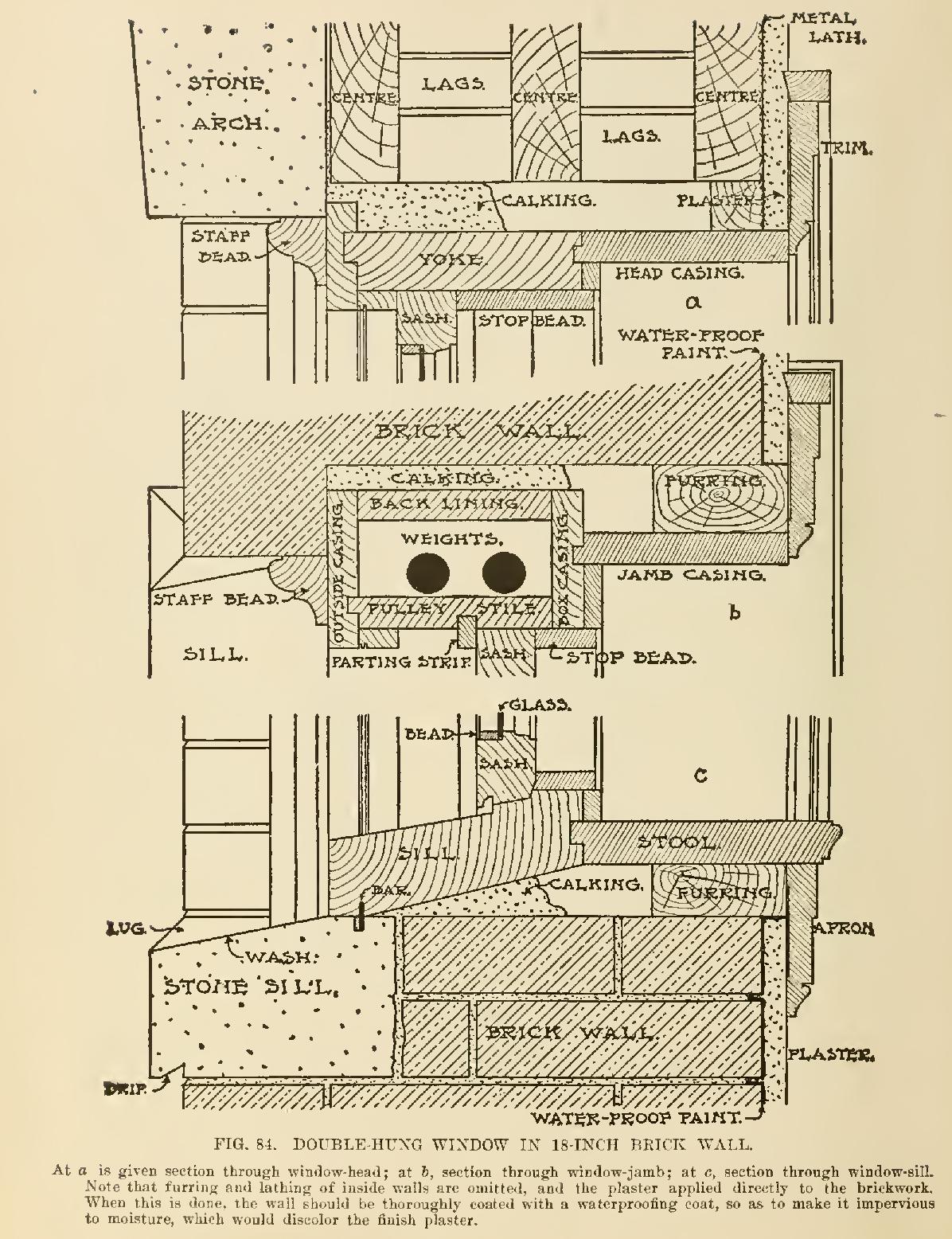

Window-Framing in Brick Walls. How window-frames are set, and the woodwork finish attached in masonry walls, is well illustrated in Fig. 76. It shows a casement window opening outward in a 13-inch brick wall. This type of construction is about the cheapest that can well be employed, excepting of course that the molded work and other features which are provided for appearance only may be greatly shnplified. These features are subject to con

siderable modifications as the taste of the architect or builder dictates.

The window opening is spanned on top by a flat stone arch, the blocks of which are cut with a camber of 1/4 inch and set with a camber of inch to every foot of span. Flat arches set in this manner give a much better effect than when set perfectly flat, inasmuch as the arch appears to sag in the center when the soffit is perfectly straight.

Back of the stone arch, a rowlock arch is turned over a wood seater, and supports the inner two-thirds of the wall if\-er the opening. These rowlock arches are segmental in form, and are built of brick set on edge; and one rowlock is provided for every foot in width of the masonry opening. All rowlocks should start at a brick impost cut to a line corresponding with the radius of the arch; and the key bricks of the lower rings should not be set until the upper rings are ready for their key bricks.

The masonry jamb of the opening is built straight, and the window-frame is secured in place by means of a lug which is left on the jamb of the frame and built into the masonry as the walls are carried up about same. This lug also serves as a wind stop.

The stone sill of the opening is cut so as to lay up accurately with two courses of brickwork, and is tailed into the masonry under each brick impost. The sill is cut with a wash, and has a lug or raised seat at each end to receive the brick imposts. On the under side of the projecting part, a water drip is cut. The stone sill should extend under the wooden sill at least two inches.

At the top, Fig. 76 is a vertical" section showing the construction at the head of the frame. The trim is mitered, put together with slip tongues, and glued. The head lining is tongued into a piece of finishing wood on the inside of the frame head.

Below is a horizontal section showing the construction at the jamb of the frame. The frame is moulded, and, where it abuts the stop bead, a channel is provided to catch any water which may beat in between the sash and frame during stormy weather. This channel conveys the water down, and discharges it on the sill. The trim is molded, built up, and hollow•-backed, and has a feather-edged At the bottom is a vertical section showing the construction at the sill of the frame. The inside stool is tongued into the wooden sill, extended into the room, and provided with brackets. The apron is molded, and has returned ends. A small mold is provided in the angle formed by the intersection of the stool and apron. A water nose is cut on the under side of the bottom rail of sash.