Grinding-Machines

GRINDING-MACHINES. This important group of ma chine-tools comprises designs for grinding practically every shape in metal work, including cylindrical (both external and internal), parallel and tapered forms, plane faces, curved and irregular out lines, and difficult forms such as gear teeth and screw threads. That extremely fine quantities of metal can be removed, is proved by the micrometer devices used for adjusting the wheel, which register to one ten-thousandth part of an inch. Emery and corundum wheels, formerly the only kinds of abrasive devices available, are now largely supplanted by the artificial products of the electric furnace, which offers great choice of fine or coarse wheels. Some of the finest work is performed in the grinding out of small holes, for which the spindles carrying the tiny wheels can be run at so,000 revolutions per minute without undue friction and heating.

In most grinding machines, it is usual to give mechanical guid ance to the work or to the wheel, in order to produce true surfaces, the work being supported upon a flat rest, and manoeuvred by the hands to produce flat faces or curves. Disc grinders form an important class, used for finishing all sorts of nuts, levers, span ners and numerous objects having flat or curved surfaces; abrasive cloth is cemented to a steel disc, which remains always flat, and is run safely at a high speed without need for a safety guard. The pieces of work are held by the hand on a flat rest (which can be tilted for bevel grinding), and are rocked to and fro across the disc by the oscillation of the arm on a supporting bar. Double disc grinders have two discs set face to f ace, the articles being passed in between them to have each face ground off parallel and simultaneously. Many machines have the disc hori zontal, in which case the work is laid on and allowed to grind itself by the pressure of gravity. If extra finish is desired, ground work is polished by machines carrying bobs or buffs charged with fine abrasive powder. Also for this work an endless band is run over pulleys and the objects to be polished are held against it by the operator.

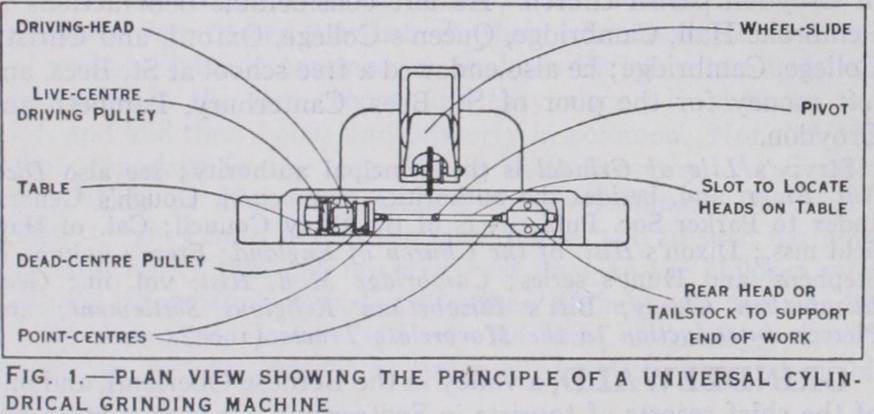

The first attempts at mechanical guidance were developed in the lathe, the slide-rest being fitted with an emery wheel instead of a steel cutting tool. This led to the design of grinding-ma chines built on the same principle, but with proper protection of the bearings and slides, the fine grit and the water applied to cool the work being very destructive to the running surfaces. There are now two distinct kinds of machine, the plain and the universal. The latter will undertake a more extensive range of operations than the former, and has a pair of heads fitted upon a table which can be swivelled on a stud (fig. I) ; graduations at the end of the table indicate the desired amount of swivel. The work has coun tersinks drilled in its ends, to rest on the point-centres, and is driven by a clamp or dog secured to it by a screw, and rotated by a pin standing out from the dead-centre pulley. Neither centre revolves in this method, and the most accurate results are obtained by the absence of any minute adverse influences from the driving spindle, which might cause eccentric running. Shafts being ground must be supported at the back in opposition to the pressure of the grinding wheel, otherwise vibrations develop. Steadies are em ployed, with wood, steel, or bronze shoes making contact with a portion of the curve. For grinding the faces of discs, and inside surfaces, a chuck is substituted for the dead-centre pulley, and the live-centre pulley then does the driving of the spindle with the chuck. Short tapers are ground by swivelling the driving head or the wheel slide.

When the table feeds to and fro for the successive cuts of the wheel on a long shaft, an automatic feed device sets the wheel in deeper at each pass. This traverse motion is eliminated in wide wheel or plunge-cut grinding, a trued wheel, sometimes many inches in width, being fed directly against the revolving piece, and completing the outline without any lateral pass. A great many pins, bolts, short shafts, etc., for motor work are ground thus. Crankshafts are finished with great accuracy on modifications of the plain grinder, the crank being chucked so that its main journal bearings revolve in an orbit, and the crank-pins run con centrically. Cams are ground with the help of a master-cam which causes a movement between wheel and cam to evolve the con tour. Modifications of the cylindrical grinding machine are con structed for tool and cutter sharpening, numerous special fittings being utilized to sharpen drills, counterbores, saws, milling-cutters and various blades and knives. An exception to the usual prac tice of supporting cylindrical work upon point centres is met with in the centreless grinders, which finish all sorts of pins, studs, rollers, etc., of moderate length, by a peculiar means of guidance between two wheels.

Internal Grinding.

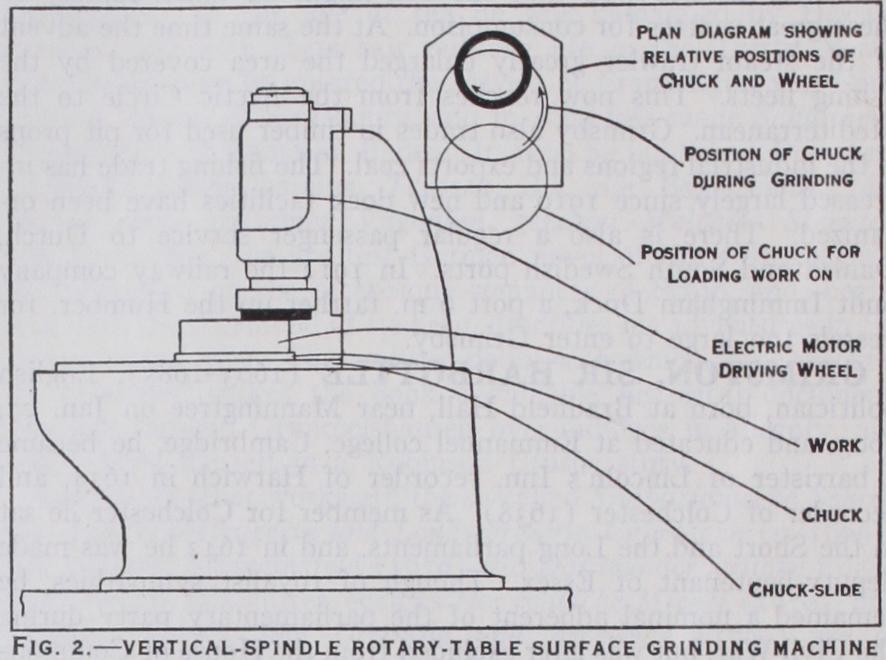

These deal specially with the various bushes, rings, collars and other pieces needing internal trueing. Hardened gear wheels are also trued in the bore, to make sure that the teeth will run truly. One type of internal grinding machine has a driving head with a chuck to hold and revolve the work at a moderate speed, while the small wheel revolving at high speed is passed in by a slide from end to end of the hole. Diameter control is exercised by a transverse adjustment of the slide. When it is not feasible to rotate the work, as is the case with many cylinder and pump castings, a planetary head is used. This has the grinding spindle contained within a drum, which can be driven round at relatively low speed, and the grinding spindle may be set anywhere from a concentric position to the full radius of the hole. (See CYLINDER.) These machines are built in both horizontal and vertical types; the latter shape is chosen for grinding out the holes in locomotive and other rods, duplex machines finishing both ends of a rod at once. The radial slot in a link can also be ground by means of a swinging arm pivoted from a centre a suitable distance away.Flat grinding is performed on several types of machines. In the rotary table design a vertical spindle usually has a chuck, on which the articles are held by clamps or by magnetism, and an edge wheel travels across. Sometimes a cup- or ring-wheel is brought down by a slide from above. The larger machines of this class assume the shape of fig. 2, but the rotating table is mounted in a slide, to enable the work to be loaded on to the chuck in the out position (see the plan) and then slide up to the working position. An alternative to the rotary table is a long rectangular one sliding straight under the wheel; or such a table may have two magnetic rotary chucks, one being under the wheel in action, while the other is free, and being cleaned off and re loaded in readiness for another transfer under the wheel. The machine is thus always in continuous operation.

Long and bulky specimens are often ground on a plainer ma chine with long table feeding between two uprights. A cross rail on these, adjustable for height, carries the grinding-wheel slide and this may be fed across the rail to cover the whole width of the table. The horizontal face grinding-machine is another design which has a long table on which big castings can be secured. The wheel is large and grinds over the complete area of the work exposed to it. Such wheels are not made as a solid big ring, which is expensive and liable to contain flaws; a circle of blocks or segments is gripped in the body. Any fracture can be remedied cheaply by the substitution of a new segment or two.

The finest method of finishing gear teeth and screw threads is by grinding. In the case of the former a thin flat-faced wheel is accurately controlled so as to move round a true curve, thereby generating the shape on each flank of each tooth in turn. Or a form wheel passes across and grinds the adjacent flanks simul taneously. The shape of the wheel is given by a diamond under control of mechanism which ensures the maintenance of an ac curate curve at all times. Screw thread flanks are ground with a carefully trued wheel, guided by a machine which eliminates small errors present in the screw, as previously cut in the lathe or arising from the hardening process. (F. H.)