Open-Hearth Process

OPEN-HEARTH PROCESS As soon as the Bessemer process attained a production stage it was found that the mild steels intermediate in carbon content, strength and ductility between carbon-free wrought iron on the one hand and high carbon crucible steel on the other, were most useful materials for machinery and engineering struc tures. These mild steels were really new materials, never before procurable in quantity, and inventors attempted to make them in ways which would not infringe the Bessemer patents. An insuperable difficulty was the inability of any fur. nace, even when burning high volatile coal under forced draft, to melt them. As in the puddling process, when the refining reached a certain stage, the metal became a pasty sponge. This obstacle was met by Sir William Siemens, who resurrected a for gotten proposal to regenerate some of the waste heat (see RE GENERATIVE FURNACE). He passed the smoke through brick chequer-work; after the passages had thus been highly heated, air for combustion of the coal was drawn through the chamber. This pre-heated air had the effect of increasing the flame tempera ture materially. Using a furnace with such a device Emile and Pierre Martin made steel at Sireuil, France in 1864, by melting a good grade of pig iron, then adding some selected wrought iron scrap which alloyed with the pig iron, continuing these additions until the carbon content was reduced to the desired percentage mainly by dilution (the Martin pig and scrap process). William Siemens (q.v.) and his brother Friedrich found it necessary to erect an experimental furnace plant in Birmingham to develop the application of their ideas in the steel industry. By 1868 the principal features of the modern open-hearth process were there developed; namely, gaseous fuel, regenerative chequer-work for pre-heating both air and gas, a thin furnace roof of silica brick and the method of refining pig iron by ore or iron oxide (the Sie mens pig and ore process). These entire furnaces, hearth, side walls and roof were made of highly siliceous refractories; the only slags which would not corrode these contain an excess of silica—so-called acid slags. Not until Thomas had shown how to remove phosphorus by a basic, high lime slag in the basic lined converter did it occur to anyone to make an open-hearth furnace Furnace Auxiliaries.—The essential furnace is often dwarfed by the auxiliaries found necessary for rapid and economical production. (See fig. 3 ; also REGENERATIVE FURNACE.) In the first place adequate fuel must be provided; consequently alongside is another building containing gas producers (q.v.) of the continuous type. A series of such producers in operation discharge gas into one main pipe from which it is drawn to the furnaces as needed. The producer house must have therefore adequate coal handling machinery; a plant with 10 6o-ton fur naces would use 40o tons of coal a day, with means for hauling or sluicing the ashes away, and boilers for raising steam to blow into the producers. Gas producers are usually found as standby equipment, even where other fuels are used, such as mixtures of blast furnace gas, by-product coke oven gas, natural gas, tar, and oil. Next a stock of adequate raw material is neces sary. If open-hearth and blast furnaces are within the same fence, melted pig iron (hot metal) will be used. That requires a mixer for intermediate storage. Otherwise an ample stock of iron in pigs is required. Furthermore a big tonnage of steel scrap of various kinds is used—the proportions of pig iron and scrap charged into steel making furnaces now depends solely upon the relative availability and cost of these two materials. Scrap must be segregated as to nature and approximate analysis; big shears and drop balls (skull crackers) are necessary for cutting and breaking unwieldy pieces ; travelling cranes and lifting mag nets are installed for economical handling of this material. Bins and stockpiles must be provided for the various special metals used for alloying or degasifying the hot steel, for the limestone, fluorspar and other fluxes, for the silica, chrome, magnesite and other fire brick to repair the furnace, for the dolomite or silica rock used for making the bottoms. In basic open-hearth plants an auxiliary building is necessary for grinding, calcining and storing the dolomite continually needed for repairing the furnace bottom and side walls (banks). Spiegeleisen, if used for a de oxidizer, must be melted in a cupola or electric furnace.

Means must be provided for introducing the fuel into the furnace, and reversing the flow of flame at frequent intervals. This requires proper valves in the flues, with an appropriate series of interlocking operating devices. Latter-day trends in furnace design call for much shorter and more direct flues than shown in the cross sectional view, and the use of water cooled gate valves offering no obstruction to gas flow when open. Waste heat boilers are also quite frequently placed between regenera tors and chimney, together with fans to pull the hot gases through them. A most interesting device is installed to charge solid mate rial through the doors into the furnace itself. By this means long delays between heats to refill the furnace are avoided, together with much exhausting labour. All solid materials are now loaded into charging boxes, cast steel trays about 24 in. wide and deep and about 4 ft. long, thus holding at least a ton of the bulkiest steel scrap. A complete charge for a furnace is assembled into or 5o such boxes, placed on a train of small flat cars, and moved to a track running close to the furnace doors. On a wide gauge track alongside, the charging machine operates. Its ram engages an end socket on the box and is locked in. The ram then lifts the loaded box off the car, moves it forward through the open door into the furnace, slews it to either side and tips it upside down, discharging its contents in the correct place. These motions are then repeated in the reverse order. When the empty box is on the car, the charging machine moves sidewise, taking with it the entire train of loaded cars until the next full box is spotted directly in front of the proper door. This is then picked up, thrust into the furnace, and dumped. In this manner a 6o ton furnace can be loaded in less than an hour. Equipment must also be installed to pour the finished steel into ingot moulds, but this is an operation which, both in the principles involved, and in practice, is similar to casting a Bessemer heat, and will be described later.

Open-hearth Steel from Cold Metal.

The basic open hearth process (1938) makes by far the most steel. Many steel making furnaces are distant from blast furnaces, so they operate entirely on cold stock, and as noted, any proportion of pig and scrap may be charged, as economics require. This process as commonly practiced in a stationary furnace and its elementary chemistry are here briefly explained. After a furnace has been tapped and the bottom and banks repaired charging is begun. Plate scrap, if available. is spread out to protect the bottom, followed by several tons of limestone, depending upon the impurities to be removed from the pig and scrap. The furnace is then filled as full as possible, with scrap, pig iron and some iron ore ; the doors are then closed, the flame given an excess of air and melting begins; as the mass melts and settles, the balance of the cold metal is added. Melting pig iron will trickle down over the white hot steel, still solid. Silicon and manganese in the pig iron droplets oxidize by the excess oxygen in the furnace atmos phere, and join with the iron oxide forming on the white hot steel and some of the lime on the bottom or furnace wall forming a slag. In four to five hours the molten metal is virtually free from silicon, and much manganese has also gone into the slag. Vigorous stirring is necessary as chemical reactions only occur at the surfaces where metal and slag are in mutual contact. This is effected principally by gases rising from the limestone, and some two hours after the metal is fluid it continues to break up, thus The gas coming to the surface in big bubbles causes a character istic boil. The lime also floats up, joining the slag as a base, not only releasing some of the iron oxide contained therein for refining reactions, such as 2P+5Fe0 = but also maintaining the basic slag necessary to dissolve and hold this phosphorus oxide. When the lime is all up further boiling in the bath is due to the chemical reaction between iron oxide and carbon (which has been going on continually but its mechanical effect somewhat overshadowed by the lime boil).

The iron oxide is dissolved by the metal from the slag. Bubbles of carbon monoxide gas evolved continue to keep the metal and slag in motion. The active refining reagent in the open-hearth furnace is the same as in the Bessemer and the earlier refining processes, namely iron oxide, but its origin is different. In the open-hearth process iron oxide is formed by oxidation of the steel during melting, picked up from the rusty scrap, and added as desired to the slag in the form of ore. During the late refining period, the furnaceman frequently takes a spoonful of metal from the bath, pours test ingots and breaks them, judging from the frac ture the content in phosphorus and carbon. It is necessary to regulate the proceedings so that phosphorus in the metal shall be down to the desired minimum some time before the carbon is down. This relative elimination can be controlled by adjusting the temperature (reversing the flow of gases more frequently increases the heat), changing the slag by adding either lime or ore, increas ing its fluidity by adding fluorspar (CaF) or increasing the carbon by adding some low-phosphorus pig iron. In about three hours the

carbon boil should subside, the bath should be low in phosphorus, and the slag essentially a high lime silicate—to hold the phos phorus; the furnace is then driven hard to increase the metal's temperature sufficiently for casting. The slag and the metal have been slowly losing iron oxide and carbon respectively by mutual interaction, and the metal gives up considerable gas held in solu tion. Since 193o much attention has been given to the relation ship between composition and viscosity of the slag existing in the refining stages and the quality of the finished steel. Slag composition is rapidly estimated on the furnace floor by pouring a small "pancake" of slag in a standardized manner and examin ing its surface, colour and fracture. Its viscosity is measured by the distance the slag flows down a pipe-stem mould. Likewise car bon in the steel may be closely estimated by rapid magnetic tests; the rate of carbon drop is also an indicator of the state of oxida tion in the heat. High grade steels are deoxidized by the con trolled slag in the furnace, after which further deoxidizing sub stances like ferromanganese or ferro-silicon may be added to the metal bath, followed by various alloying elements like chromium if an alloy steel is to be made. When the word is given, the furnace crew thrusts a long heavy bar through an opening in the centre door, across the furnace into the bath; several battering-ram thrusts break through the plugged tap hole, and white-hot metal rushes down the spout into a ladle set be neath. This ladle is just large enough to hold the steel; slag which follows after overflows into a pit or slag ladle alongside.

Use of Molten Pig.

Various methods deviate from the above routine and have been devised to adapt the open-hearth process to the economic conditions to be met by the steel-maker, espe cially as to the relative amount of scrap steel and molten pig iron available. These range from processes for handling a prepond erance of scrap and a minor amount of molten pig iron (as is usual in America) to the Talbot process described below for handling up to 8o% hot metal (as is practiced in England, 1939).

In American stationary furnaces of, say, 'co tons capacity the limestone and scrap are charged as indicated above and heated strongly until well melted. During this time the slag forms from oxidized iron and calcined lime. Within two hours all but the heaviest scrap has melted and molten pig iron is poured in. A rapid reaction starts between the iron oxide in slag and melted scrap and the carbon, phosphorus, and silicon in the molten pig iron. Carbon oxides boiling up through the slag cause it to froth and swell and much of this "flush slag" flows off through a hole in the back of the furnace well above the normal shore line. This slag carries a little sulphur, and much of the silicon, phosphorus and manganese in the pig iron, and the amount of finishing slag is correspondingly reduced.

Continuous Steel Making.

Benjamin Talbot first built furnaces for continuous production of steel at Pencoyd, Pa., in 1899, although the Talbot process is more popular in England (1939). Furnaces are of large capacity-200 to 30o tons of metal —and are mounted like a mixer on trunnions; they can be tilted forward and slag skimmed or metal poured through a spout, normally far above the liquid bath. Most of the finishing slag and about 1 o tons of steel from the previous heat are retained in the furnace and on this is charged enough burnt lime and ore so the first slag can be removed when the metal is 0.30% carbon above that desired. After heating the slag and furnace for 2 hours scrap as available is charged, heated another 2 hours, and about three-quarters of the required molten pig iron is poured in. Re action is vigorous for about 4 hours, and then the remainder of the hot metal is added. The bath quickly comes to a good boil and the slag is carefully skimmed off 1 hour later. This slag carries most of the phosphorus; it may analyze 17% P205 and is a valuable by-product. The finishing slag is then made up of lime and scale (iron oxide) and the bath worked until carbon, sulphur, and phosphorus in the metal are reduced to the required point, taking about 3 hours, whereupon ferromanganese is added and the steel is poured into waiting ladles. The analysis can be "caught on the run," and held for adjustments, alloying, or mak ing up a second refining slag. The process, therefore, in addition to consuming large proportions of hot metal, is able to produce quality steels of varying specifications at will, thus being a proto type of the electric furnace, to be described later.

Duplex Processes.

Other means of speeding the rather delib erate open-hearth reactions are used extensively, perhaps the most important being a combination of acid Bessemer and basic open hearth. This enables the steel-makers to start with a high sulphur ore, smelting it to a high silicon, low sulphur pig iron, blowing the silicon and carbon out in a converter, and transferring the molten steel to a large tilting furnace where the phosphorus, oxide and gases are eliminated. In American practice 250-ton tilting fur naces are used ; 5o tons of molten steel are reserved in the hearth, a highly basic combination of ore and lime is charged, melted, and about iso tons of blown metal poured in. When the temperature and slag are correctly adjusted, a ladle of basic pig iron from a mixer is charged. A strong carbon boil ensues immediately, and the slag foams up and overflows, carrying much of the phosphorus and some sulphur. When the first reaction quiets down, a second ladle of pig iron causes it to resume, and drives out the rest of the phosphorus. The slag is then skimmed off, enough pig iron is added to bring the carbon to the desired percentage, and the metal finished and superheated for pouring. From such a fur nace, 200 tons of steel can be taken every 3 or 4 hours.

Duplex processes of the sort described but using two open hearth furnaces originated in Germany and are used for irons somewhat too low in phosphorus for the basic converter. In the first furnace, run at a rather low temperature, the phosphorus and silicon are eliminated into a lime slag rich enough for use as a fertilizer. The furnace is tapped, the slag separated, and the metal introduced into another and hotter furnace, wherein awaits a proper slag for rapid carbon elimination. This is called the Ber trand-Thiel process ; the Hoesch modification recharges the partly purified metal back into the furnace from which it has just been drained. Super-refining molten basic steel in an electric furnace is another variety of duplexing which has been practised in Amer ica; by eliminating sulphur and oxidizing particles, good steel is made, but the difficulty of co-ordinating operations to avoid idle stand-by of costly furnaces has prevented the wider adoption of duplex processes.

Acid Steel.

Furnaces made with siliceous bottoms and banks, the descendants of the original open-hearth furnaces, still exist in considerable number. They make steel under slags which are essentially mixtures of iron, manganese and silicon oxides, having well over 5o% of the latter, and are so quite acid in nature. Such acid steel has an enviable reputation for quality, but since the furnace reactions remove neither sulphur nor phosphorus, the raw materials and fuel must be selected with much more care.

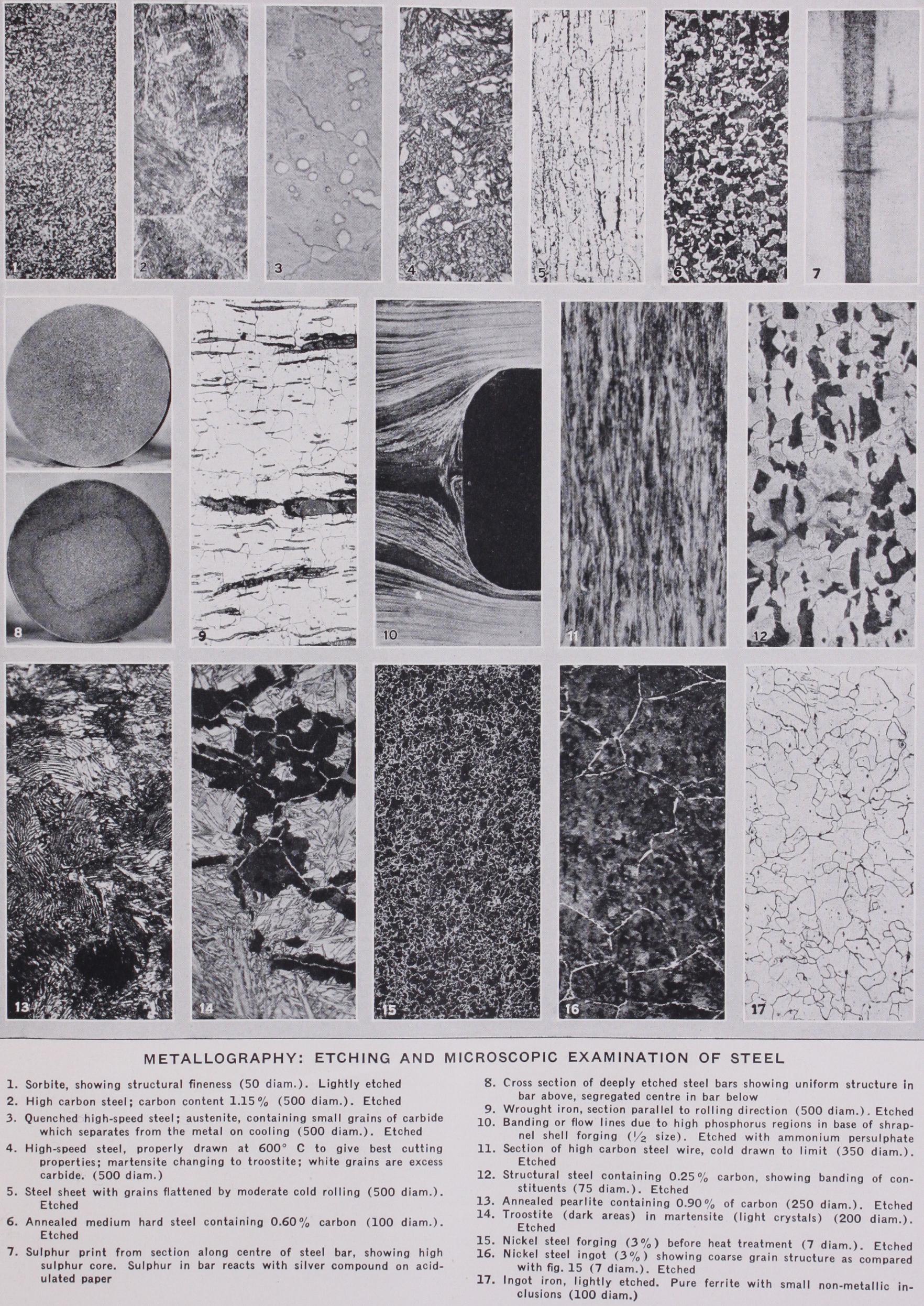

Pig and scrap, as available, are charged cold into the furnace, which has a higher roof to withstand the higher refining tempera ture; during melting, nine-tenths of the manganese and silicon are oxidized, and join with the rust and burned iron to 'form a slag. Carbon is eliminated slowly by reaction with the iron oxide in the slag ; a little ore is added some two hours after the charge is well melted to keep this reaction going until the residual car bon in the metal equals that required in the steel being made. Temperature is driven higher and higher. Toward the end of this refining period—which may require seven hours—some man ganese and silicon re-enters the metal, reduced from the slag by reversible chemical reactions, and are very effective in removing oxygen and other dissolved gases. At the end the metal is slowly losing carbon but gaining manganese and silicon. However, man ganese is still too low for most steel specifications, so an appro priate amount of ferro-manganese is added some 20 min. before tapping. A complete cycle of operations may require up to 16 hours when making steels for ordnance. The superiority of acid open-hearth steel is due to the better grade of raw material used, the small amount of slag formed (perhaps 7% of the metal), the more deliberate working of the heat enabling the furnaceman to bring his metal to the right analysis without making large addi tions of alloys, and the ability to eliminate gases and non-metallic impurities from a super-heated fluid metal while it is still in the furnace.